A High Frequency Omnidirectional Velocity Geophone

A geophone and speed-type technology, applied in seismic signal receivers, seismology, instruments, etc., can solve the problems of reduced resource utilization, low sensitivity of geophones, scrapping of geophones, etc., to facilitate field construction and reduce The difficulty of construction and the effect of reducing scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

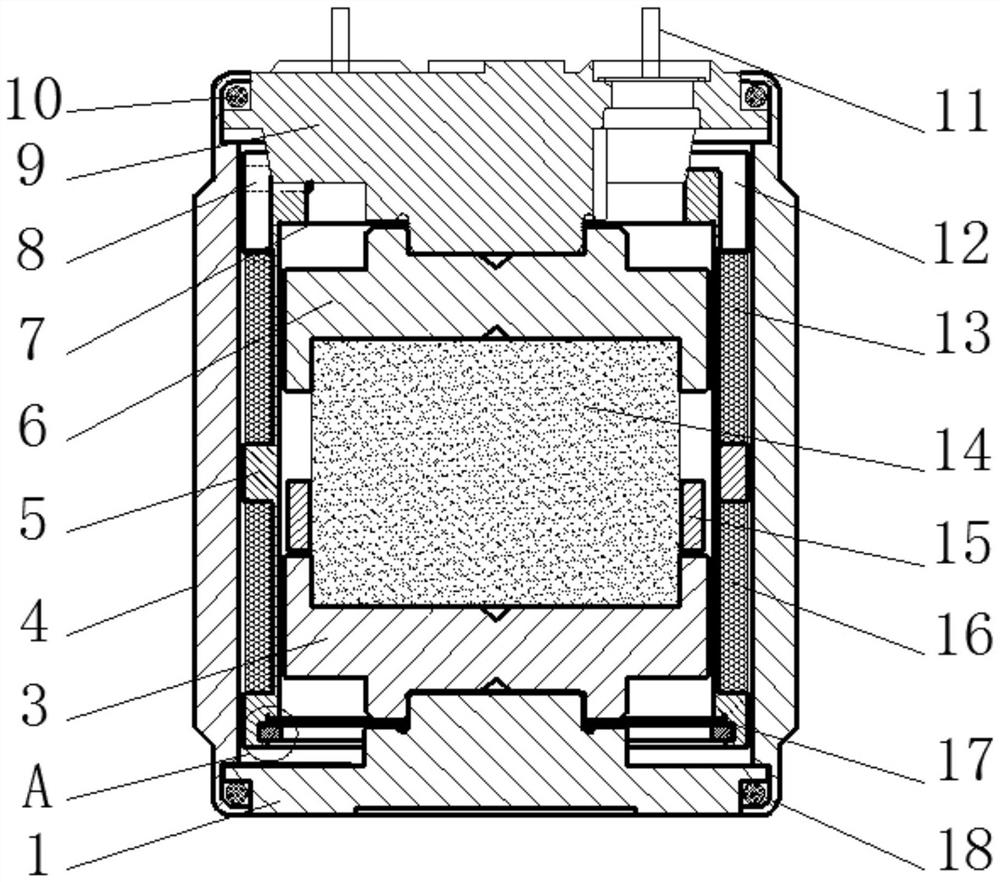

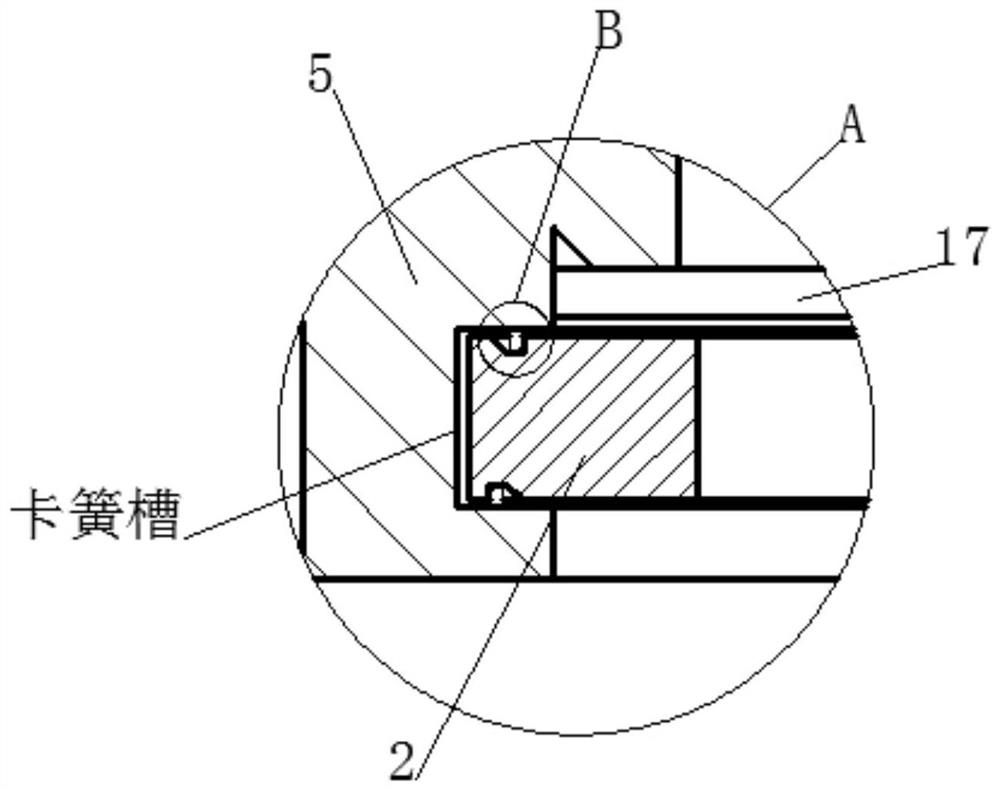

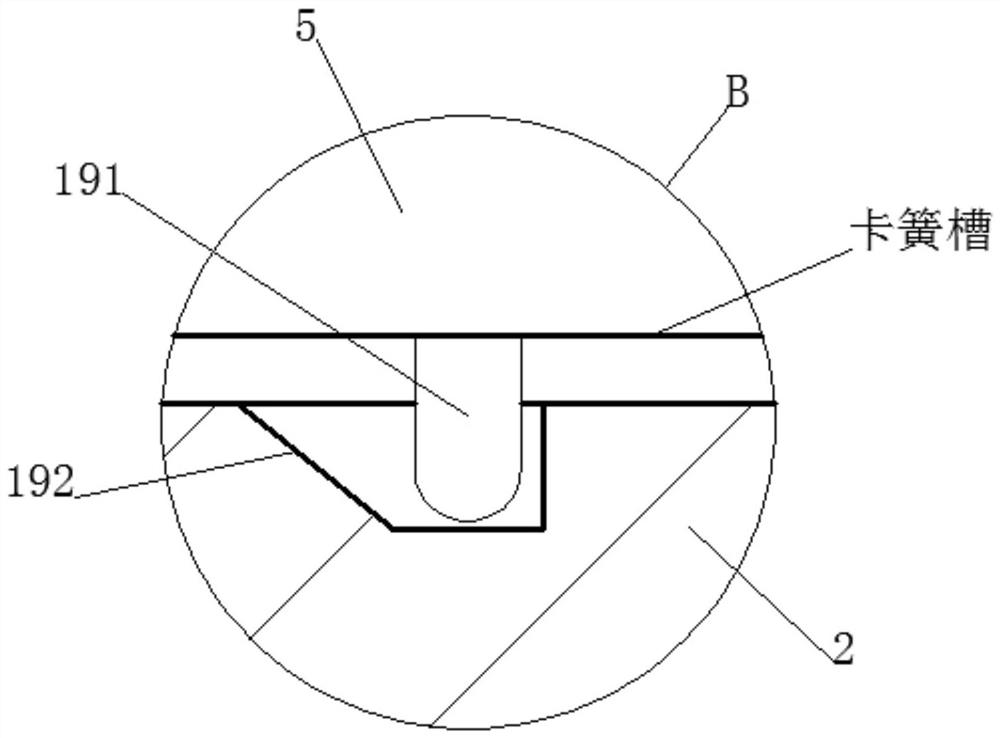

[0040] see figure 1 , a high-frequency omnidirectional velocity geophone, including a shell assembly and a coil assembly, the coil assembly is located in the shell assembly, the shell assembly includes a bottom cover 1, a shell 4 and a top cover 9, and the top cover 9 and the bottom cover 1 are respectively installed in the shell The upper and lower ends of 4, and between the top cover 9, the bottom cover 1 and the casing 4 are respectively provided with an upper sealing ring 10 and a lower sealing ring 18, and the upper sealing ring 10 and the lower sealing ring 18 are used to ensure the tightness in the casing 4 , so that in the process of use, it is difficult for external moisture or some mud and other sundries to enter the casing 4, thereby reducing the influence of moisture or mud and other sundries on the geophone, thereby improving the service life of the geophone An insulator 11 is installed on the upper end of the top cover 9, and the thickness of the casing 4 is grea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com