Broadband electrostatic micro-energy collector and collection system, and preparation method of collector

A collection system and micro-energy technology, applied in induction generators and other directions, can solve the problems of large vibrator mass of energy harvester, narrow energy collection frequency range, and unadjustable resonance frequency, achieving adjustable resonance frequency and wide application range. , the effect of easy miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

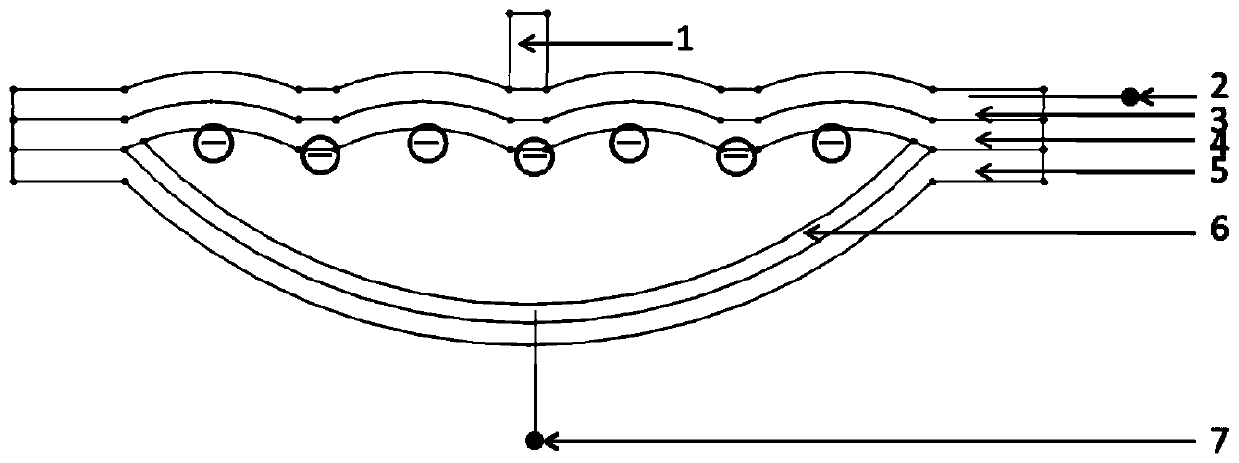

[0049] A broadband electrostatic micro-energy harvester, such as figure 1 As shown, the upper electrode 3, the high elastic polymer film 4, the lower electrode 6 and the bracket 5 are arranged in sequence, and the mass 1 fixedly bonded to the middle position of the upper electrode 3, and the upper electrode lead 2 connected to the upper electrode 3 and the lower electrode lead 7 connected to the lower electrode 6; the upper electrode 3 and the high elastic polymer film 4 are bonded and connected; the middle part of the support 5 is provided with a groove in the direction away from the high elastic polymer film 4, and the groove is an arc shaped groove; the two ends of the bracket 5 are attached to the high elastic polymer film 4; the lower electrode 6 is attached to the inside of the groove; a cavity is formed between the lower electrode 6 and the high elastic polymer film 4.

[0050]The specific materials and processing methods of each part in this embodiment are: one side su...

Embodiment 2

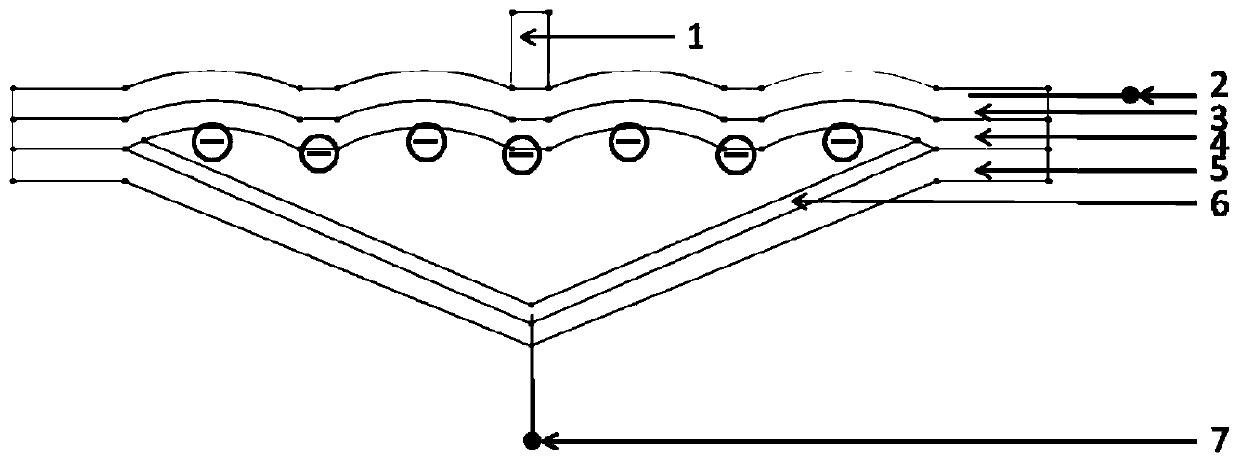

[0058] A broadband electrostatic micro-energy harvester, such as figure 2 As shown, the upper electrode 3, the high elastic polymer film 4, the lower electrode 6 and the bracket 5 are arranged in sequence, and the mass 1 fixedly bonded to the middle position of the upper electrode 3, and the upper electrode lead 2 connected to the upper electrode 3 and the lower electrode lead 7 connected to the lower electrode 6; the upper electrode 3 and the high elastic polymer film 4 are bonded and connected; the middle part of the bracket 5 is provided with a groove in the direction away from the high elastic polymer film 4, and the groove is triangular The groove; the two ends of the bracket 5 are attached and connected with the high elastic polymer film 4; the lower electrode 6 is attached inside the groove; a cavity is formed between the lower electrode 6 and the high elastic polymer film 4.

[0059] The specific materials and processing methods of each part in this embodiment are: on...

Embodiment 3

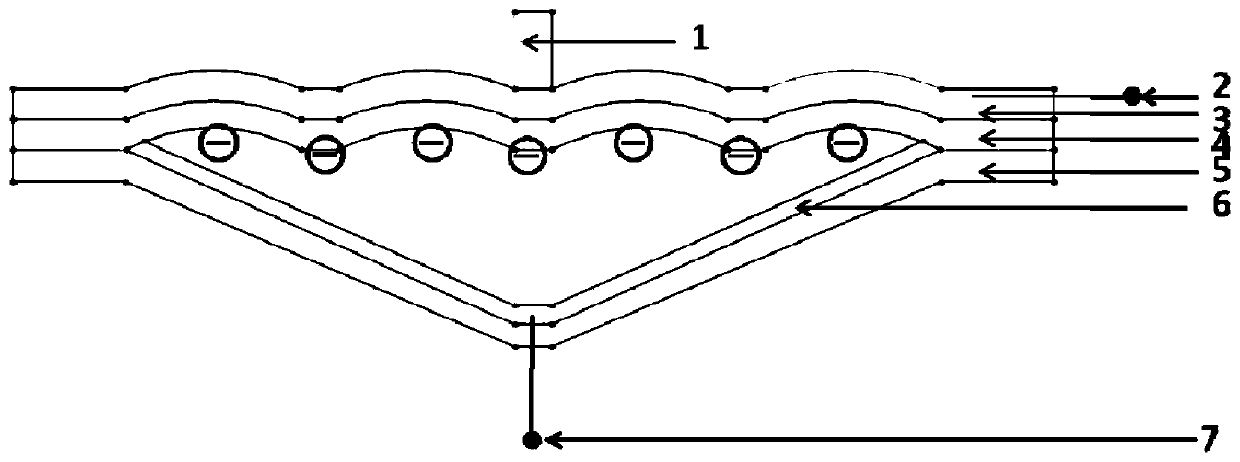

[0067] A broadband electrostatic micro-energy harvester, such as image 3 As shown, the upper electrode 3, the high elastic polymer film 4, the lower electrode 6 and the bracket 5 are arranged in sequence, and the mass 1 fixedly bonded to the middle position of the upper electrode 3, and the upper electrode lead 2 connected to the upper electrode 3 and the lower electrode lead 7 connected to the lower electrode 6; the upper electrode 3 and the high elastic polymer film 4 are bonded and connected; the middle part of the bracket 5 is provided with a groove in the direction away from the high elastic polymer film 4, and the groove is trapezoidal The groove; the two ends of the bracket 5 are attached and connected with the high elastic polymer film 4; the lower electrode 6 is attached inside the groove; a cavity is formed between the lower electrode 6 and the high elastic polymer film 4.

[0068] The specific materials and processing methods of each part in this embodiment are: on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com