Vapor plate reinforced server heat dissipation device and method based on thermoelectric refrigeration technology

A technology of thermoelectric refrigeration and heat dissipation device, which is applied in the direction of electrical components, structural parts of electrical equipment, cooling/ventilation/heating transformation, etc. and other problems, to achieve the effect of small occupied volume, fast cooling speed, and reduced thermal conduction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

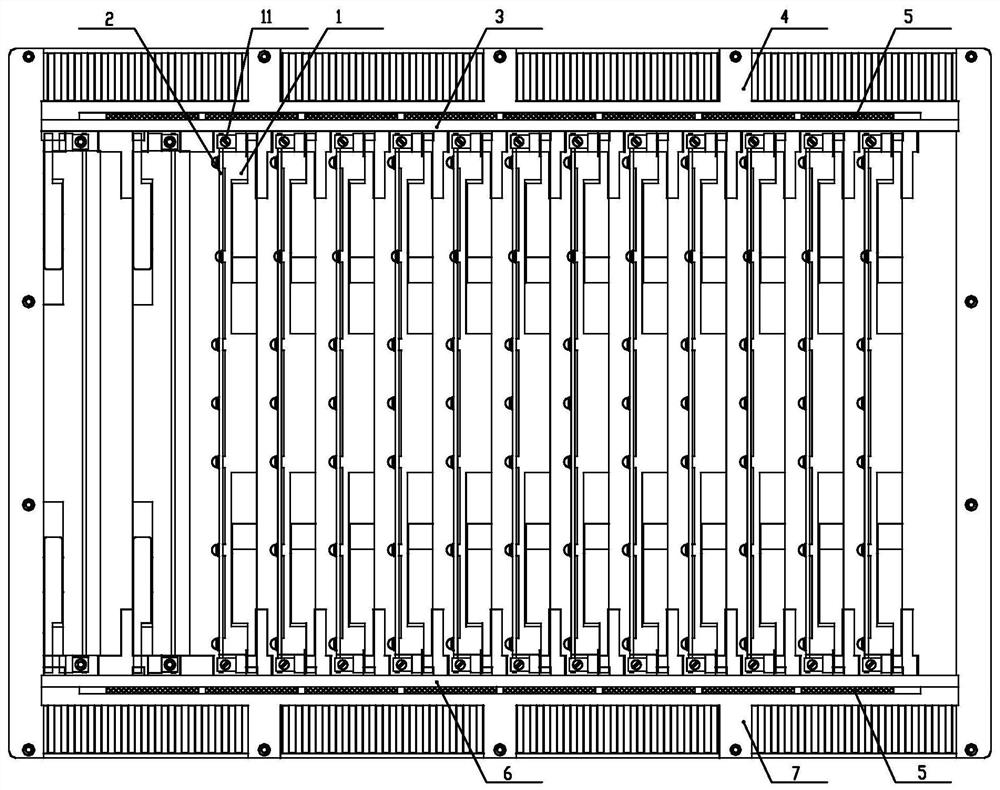

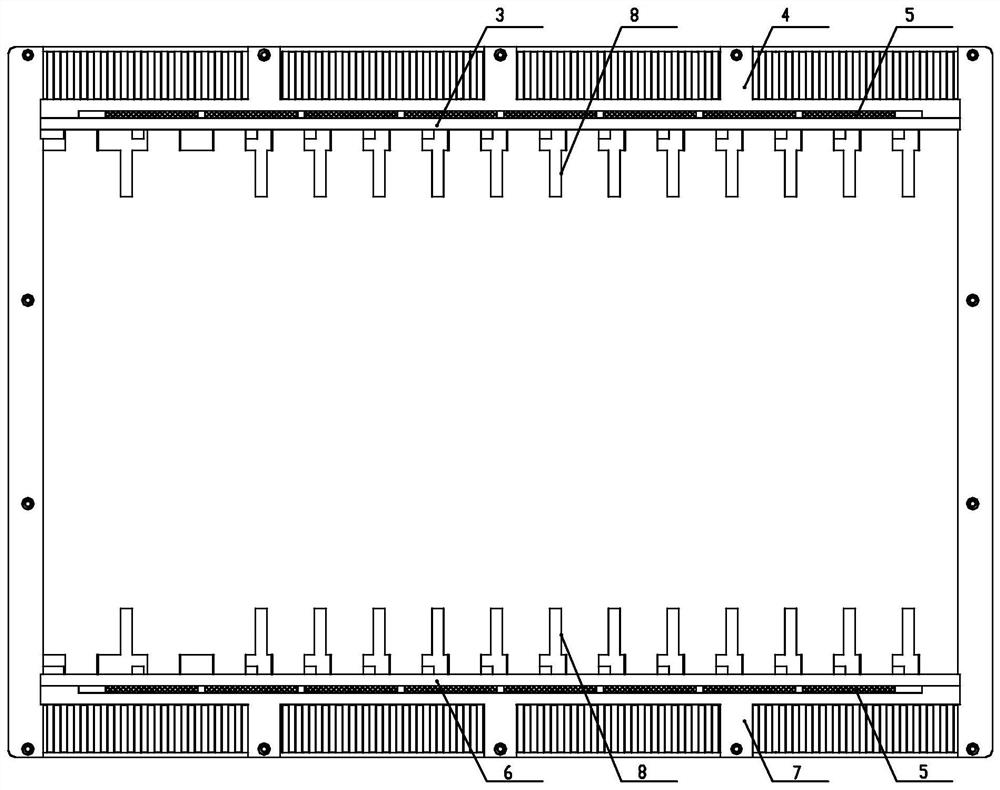

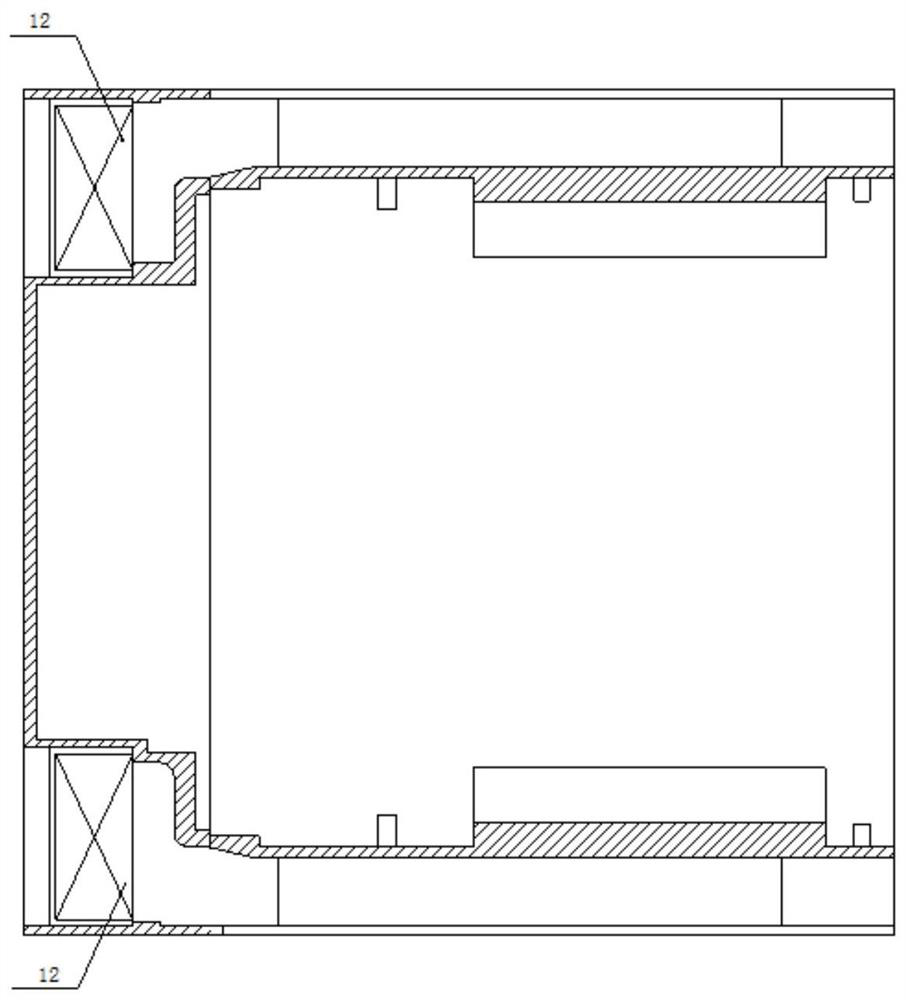

[0039] Such as figure 1 , 2 As shown, the vapor chamber reinforced server based on thermoelectric refrigeration technology includes a vapor chamber cold plate 1, a printed board 2, an upper slot plate 3, a lower slot plate 6, a thermoelectric cooling sheet 5, an upper vapor chamber radiator 4, Lower vapor chamber radiator 7, axial fan 12. The upper and lower slot plates are provided with heat conducting bosses 8, one end of the heat conducting bosses 8 is connected to the upper and lower slot plates, and the other end extends toward the inside of the heat sink; The plate heat conduction boss 8 contacts, the printed board 2 is fixed on the soaking plate cold plate 1, the heat of the heating element on the printed board 2 is conducted to the upper and lower slot plate bosses 8 through the soaking plate cold plate 1, and then the upper , the boss 8 of the lower slot plate is conducted to the thermoelectric cooling sheet 5, and then the thermoelectric cooling sheet 5 is conducte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com