A kind of nitrogen/sulfur co-doped porous cellulose adsorbent and preparation method and application

A porous cellulose and co-doping technology, applied in the field of water treatment, can solve the problems of hexavalent chromium adsorption capacity, selectivity and affinity to be further improved, and achieve excellent adsorption rate, wide range of sources, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

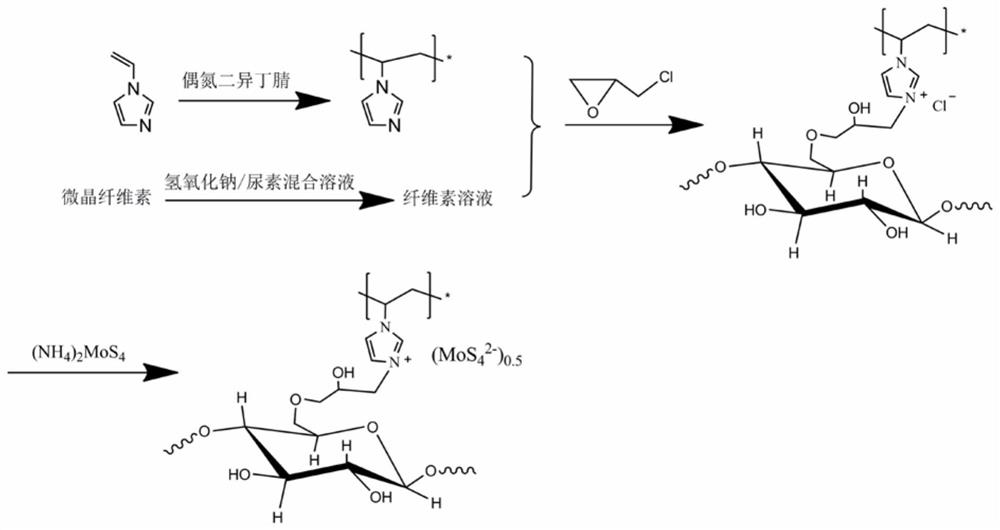

[0041] (1) Preparation of polyvinylimidazole: 10 parts by volume of vinylimidazole, 0.2 parts by mass of azobisisobutyronitrile, and 55 parts by volume of toluene were reacted at 70° C. for 4 hours to obtain white polyvinylimidazole powder.

[0042] (2) After adding 0.125 parts by mass of polyvinylimidazole to 15 parts by volume of 28wt% urea solution for dissolution, add 13 parts by mass of 4wt% cellulose solution (7wt% sodium hydroxide, 12wt% urea), and stir for 5 hours at room temperature well mixed.

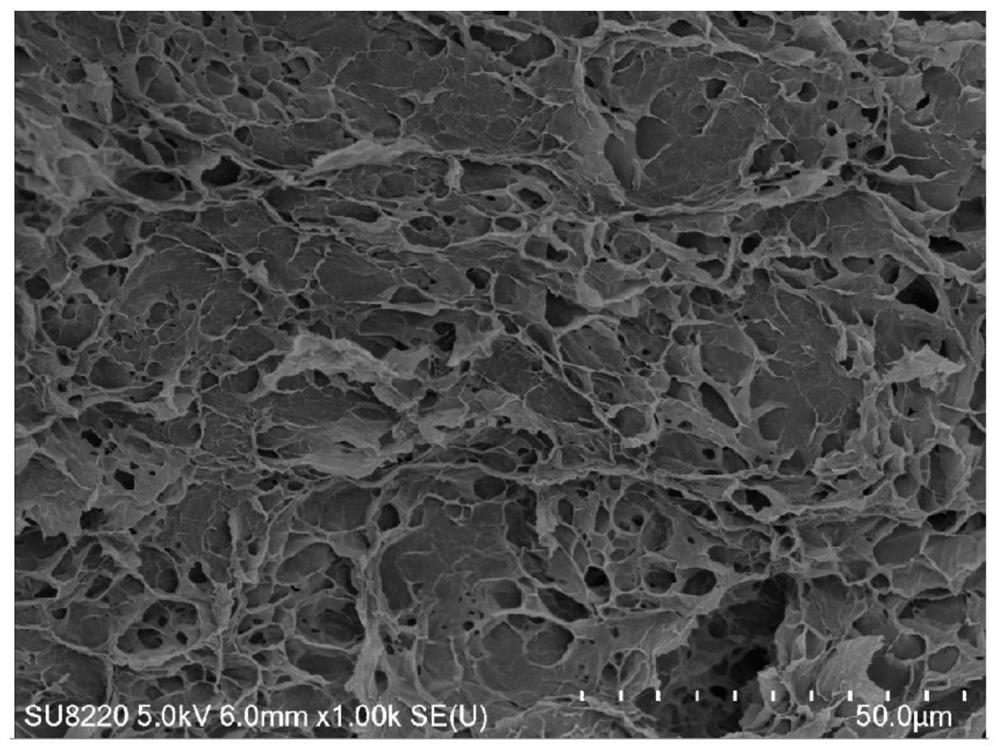

[0043] (3) Add 2 parts by volume of epichlorohydrin to the system of step (2), so that the mass-volume ratio of cellulose, polyvinylimidazole, and epichlorohydrin is 4:1:16, and stir at 0°C for 1 hour , the obtained transparent solution was placed in an oven at 60° C. for 1 h, and the obtained solid sample was washed several times with deionized water and tert-butanol, and then freeze-dried.

[0044] (4) Add 0.1 parts by mass of the solid sample obtained in step (3) into 100...

Embodiment 2

[0047] (1) After adding 0.330 parts by mass of polyvinylimidazole to 15 parts by volume of 28wt% urea solution for dissolution, add 13 parts by mass of 4wt% cellulose solution (7wt% sodium hydroxide, 12wt% urea), and stir for 12 hours at room temperature well mixed.

[0048] (2) Add 2 parts by volume of epichlorohydrin to the system of step (1), so that the mass-volume ratio of cellulose, polyvinylimidazole, and epichlorohydrin is 3:4:12, and stir at 5°C for 2 hours , the obtained transparent solution was placed in an oven at 50° C. for 2 h, and the obtained solid sample was washed several times with deionized water and tert-butanol, and then freeze-dried.

[0049] (3) Add 0.15 parts by mass of the solid sample obtained in step (2) into 100 parts by volume of 0.75 g / L ammonium tetrathiomolybdate solution, and stir at room temperature for 36 hours. After the reaction, the obtained solid sample was washed several times with deionized water, and then vacuum-dried for 24 hours to...

Embodiment 3

[0052] (1) After adding 0.167 parts by mass of polyvinylimidazole to 15 parts by volume of 28wt% urea solution for dissolution, add 25 parts by mass of 2wt% cellulose solution (7wt% sodium hydroxide, 12wt% urea), and stir for 8 hours at room temperature well mixed.

[0053] (2) Take 2 parts by volume of epichlorohydrin and add it to the system of step (1), so that the mass volume ratio of cellulose, polyvinylimidazole, and epichlorohydrin is 3:2:12, after stirring for 3 hours at 0°C , the obtained transparent solution was placed in an oven at 70° C. for 4 h, and the obtained solid sample was washed several times with deionized water and tert-butanol, and then freeze-dried.

[0054] (3) Add 0.2 parts by mass of the solid sample obtained in step (2) into 100 parts by volume of 0.75 g / L ammonium tetrathiomolybdate solution, and stir at room temperature for 48 hours. After the reaction, the obtained solid sample was washed several times with deionized water, and then freeze-dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com