High-resistivity recycled concrete and preparing method thereof

A technology of recycled concrete and high resistivity, which is applied in the field of building materials to achieve the effects of cost saving, high porosity and improved resistivity

Inactive Publication Date: 2019-07-30

JIANGSU CHENGGONG CONSTR TECH +1

View PDF4 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] In order to solve the technical problem of how to improve the resistivity of concrete and improve the recycling rate of resources, a kind of recycled concrete with high resistivity is provided

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

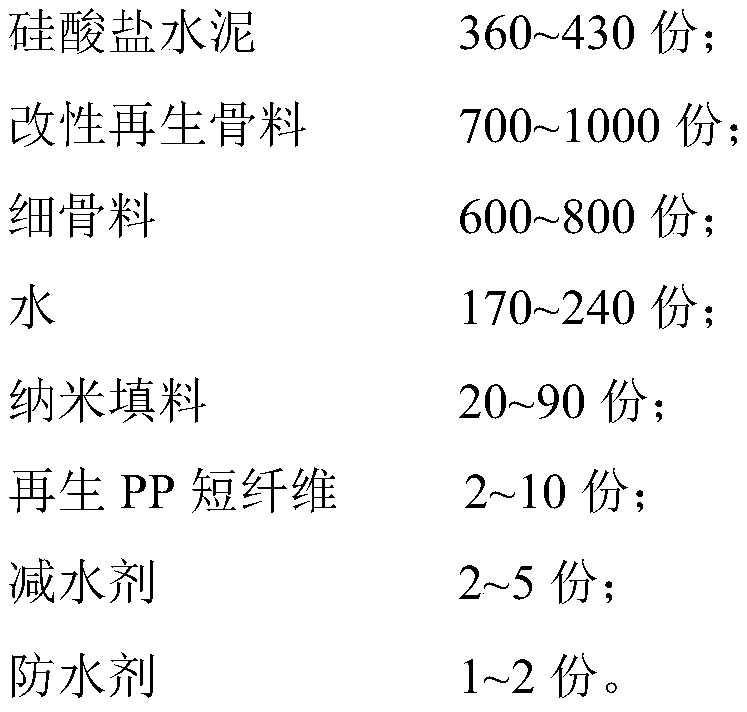

[0027] The high resistivity recycled concrete of the present embodiment comprises the following raw materials in parts by weight:

[0028]

[0029]

Embodiment 2

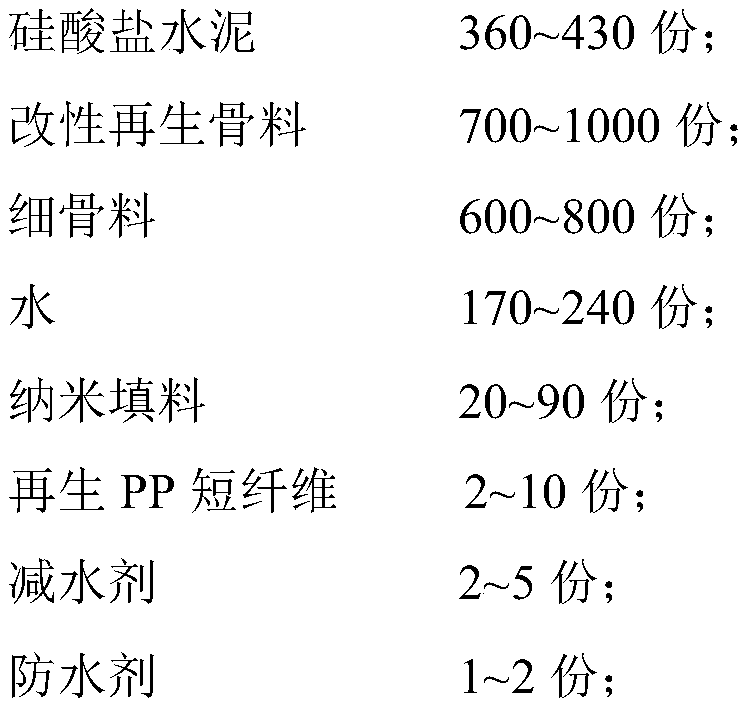

[0031] The high resistivity recycled concrete of the present embodiment comprises the following raw materials in parts by weight:

[0032]

Embodiment 3

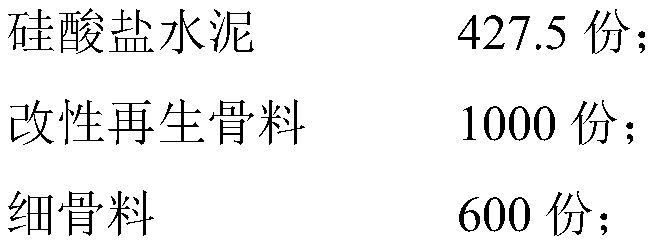

[0034] The high resistivity recycled concrete of the present embodiment comprises the following raw materials in parts by weight:

[0035]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides high-resistivity recycled concrete and a preparing method thereof. By preparing recycled aggregates and recycled PP short staples from solid waste, the disposal problem of concrete waste and PP waste is solved, resources can be better recovered and sufficiently used, and cost is saved. The recycled aggregates have low water absorptivity after being modified, nanometer fillerwith a certain length-diameter ratio has an adsorption effect on gaps in the recycled aggregates, and the resistivity of the recycled concrete can be further improved. The recycled PP short staples make great contributions to improving the resistivity of the recycled concrete. The recycled concrete has high resistivity, the chloride ion content is smaller than 0.1% when the resistivity is 20 Kohmcm or above, the compressive strength can reach 50 MPa or above, the strength of the recycled concrete is ensured, high resistivity is realized, and meanwhile the later-period maintenance cost of subway projects and large power plant projects is greatly reduced.

Description

technical field [0001] The invention relates to the field of building materials, in particular to a high-resistivity recycled concrete and a preparation method thereof. Background technique [0002] Concrete is a building material with a long history of development. Because of its good performance, it has been widely used in various structural projects. [0003] As social development promotes the process of urbanization, population migration to cities is accelerated. This makes the traffic in the city very congested, and the existing traffic facilities are unable to bear the excessive flow of people. In order to alleviate the traffic pressure in cities, various cities have begun to intensify their efforts to build subway facilities. Usually when the subway is running, it is difficult to completely insulate it from the ground. Some current will flow from the track to the nearby ballast bed or the soil in the surrounding area to form an electric field. Due to the potential ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B28/04C04B111/92

CPCC04B28/04C04B2111/92C04B2201/50C04B18/16C04B14/068C04B14/102C04B16/0633C04B2103/302C04B2103/65

Inventor 史贵才丁川黄小红操林海

Owner JIANGSU CHENGGONG CONSTR TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com