Sewage pipeline inspection well desilting device and method

A technology for sewage pipelines and dredging devices, which is applied in water supply devices, waterway systems, buildings, etc., can solve the problems of large equipment obstructing traffic, large area of silt suction trucks, harsh environment, etc., to achieve rapid automatic silt salvage, convenient The effect of bagged transportation and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

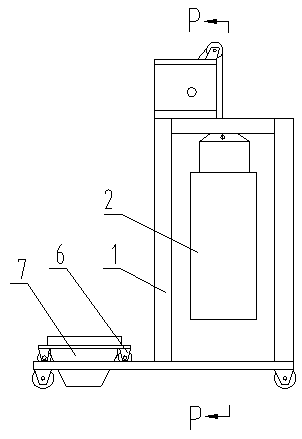

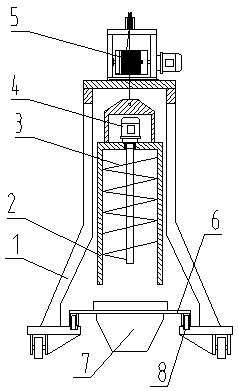

[0020] Such as figure 1 and figure 2 Shown is an embodiment of the dredging device for inspection wells of sewage pipelines of the present invention, comprising a frame 1, a hoist 5 installed above the frame 1, a bucket 2 lifted by the hoist 5, a spiral blade 3 installed in the bucket 2, and the bucket The mouth of the bucket 2 is downward, and the spiral blade 3 is driven by a motor 4 installed on the top of the bucket 2.

[0021] Rollers are installed on the bottom of the frame 1 to facilitate the movement of the device.

[0022] Also includes the shuttle car 6, the guide rail 8 for the shuttle car 6 is set on the bottom of the frame 1, the shuttle car 6 is equipped with a feed bin 7, after the bucket 2 is lifted by the hoist 5, the feed bin 7 can run to the bucket 2 with the shuttle car 6 Directly below.

[0023] The motor 4 is equipped with a torque measuring device and a control device. When the torque exceeds a set value, the motor stops automatically to prevent the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com