Ceiling putty leveling troweling machine

A ceiling and plastering machine technology, which is applied in the direction of construction and building construction, can solve the problems of affecting occupational health and safety, increasing the pressure of blood supply, and low accuracy of plastering, so as to improve the efficiency of plastering work and have a high degree of automation , smoothing effect with high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

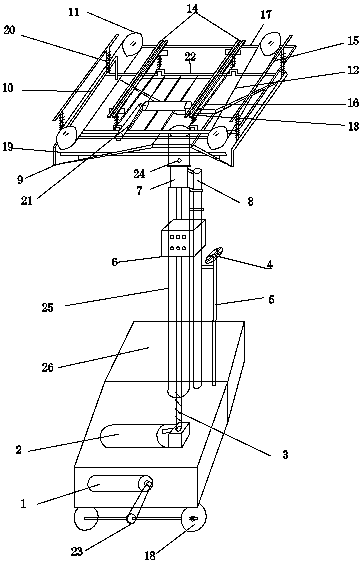

[0008] The structure diagram of the present invention is as figure 1 As shown, the ceiling putty leveling and plastering machine of the present invention includes a lifting motor 2, a screw rod 3, a steering compass 4, a control box 6, a connecting pipe 7, a guide rod 8, a bracket 9, a skeleton 10, and four sprockets 11 , chain 12, scraper driving motor 13, plastering knife track 14, automatic lifting sensor switch 15, sprocket rotating shaft 17, travel switch 24, vertical rod 25, base 26, wherein lifting motor 2 and vertical rod 25 are installed on base 26 and the output shaft of the lifting motor 2 is connected with the screw rod 3, the nut fixed on the vertical rod 25 and the screw rod 3 form a screw transmission pair, the vertical rod 25 is connected with the steering compass 4, and the travel switch 24 is installed on the vertical rod 25 , the bracket 9 is connected to the top of the vertical rod 25, the output shaft of the scraper drive motor 13 is connected with the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com