An optimization method for buoyancy block configuration of deepwater drilling riser system based on genetic algorithm

A configuration optimization and genetic algorithm technology, applied in the field of offshore oil and gas engineering, can solve the problems of complicated riser operation process, prolonged operation time, and aggravated vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] combined with Figure 1-6 , to further describe the present invention.

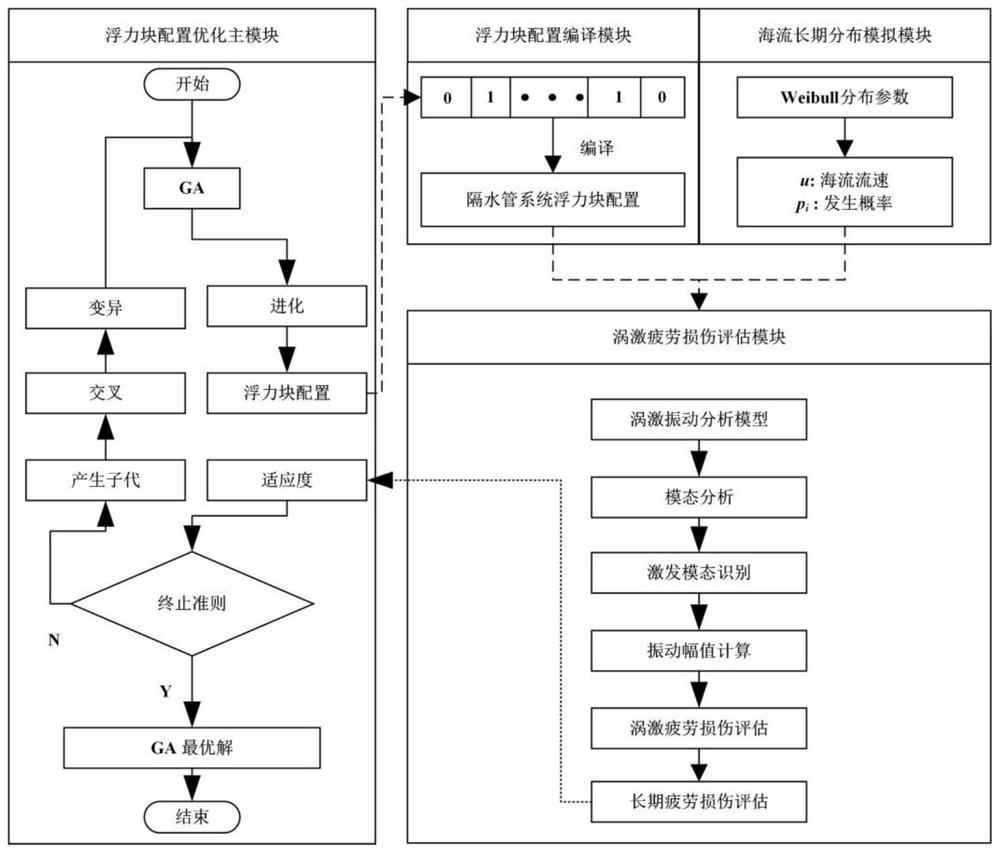

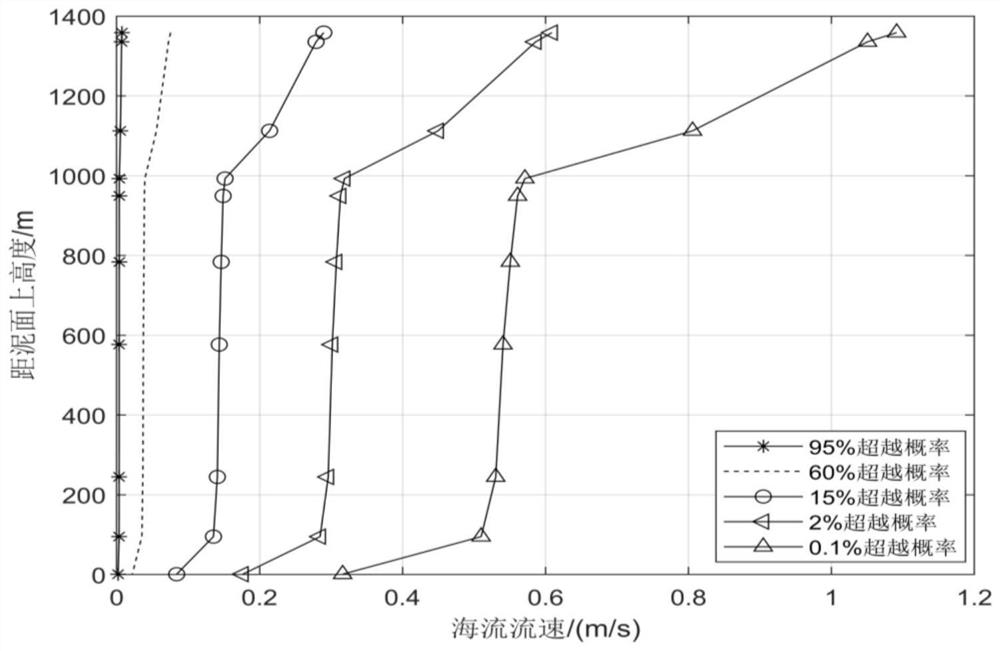

[0038] An intelligent optimization method for buoyancy block configuration of deepwater drilling riser system based on vortex-induced suppression, the specific implementation plan is as attached figure 1 As shown, the whole analysis process mainly includes the main module of buoyancy block configuration optimization, buoyancy block configuration compilation module, long-term ocean current distribution simulation module and vortex induced fatigue damage assessment module.

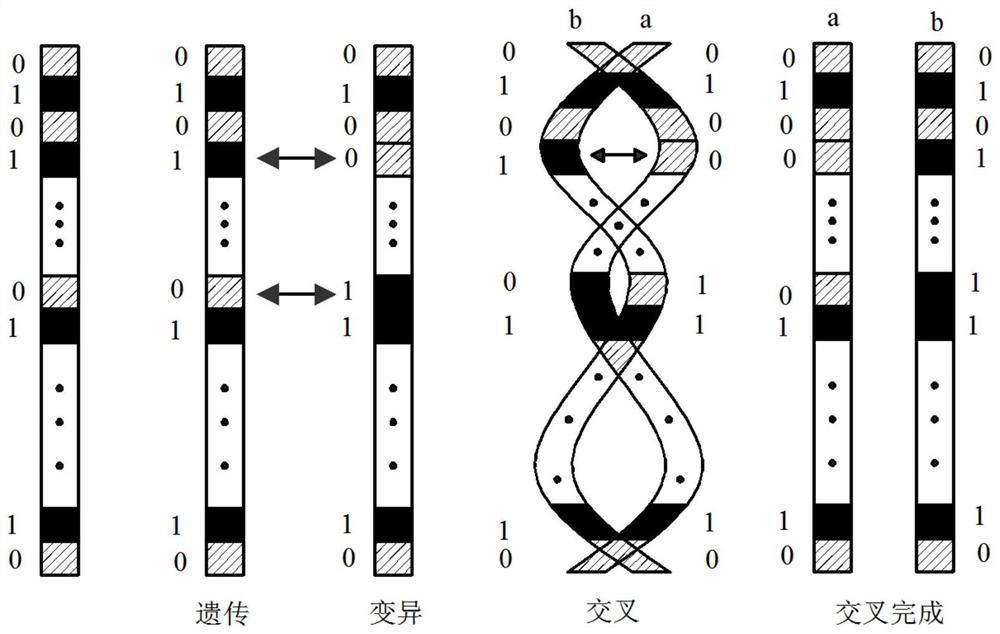

[0039] Module 1: Buoyancy block configuration optimization module, this module is mainly based on genetic algorithm for gene population generation, crossover, mutation and selection of different buoyancy block configurations, as shown in the attached figure 2 It is the inheritance, variation and crossover process of the gene population. Gene 1 represents a single buoyant block, and gene 0 represents a bare single root. Differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com