Machine-made sand quality detection equipment and detection method thereof

A technology for testing equipment and machine-made sand, applied to measuring devices, by removing certain components, weighing, instruments, etc., can solve problems such as unreliability, blurred images, and unreliable images, so as to improve reliability and measurement accuracy , The effect of eliminating the difference in test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

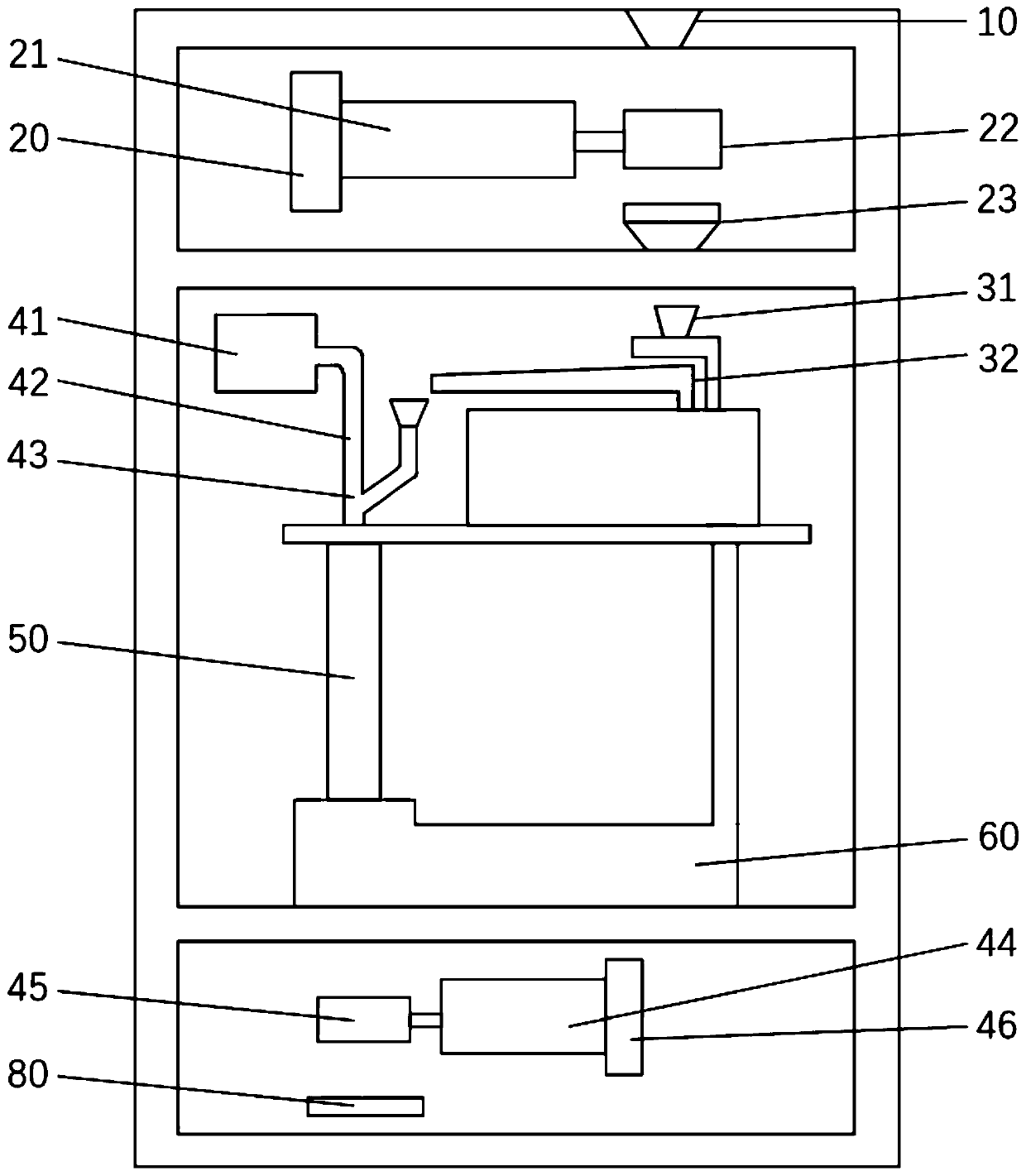

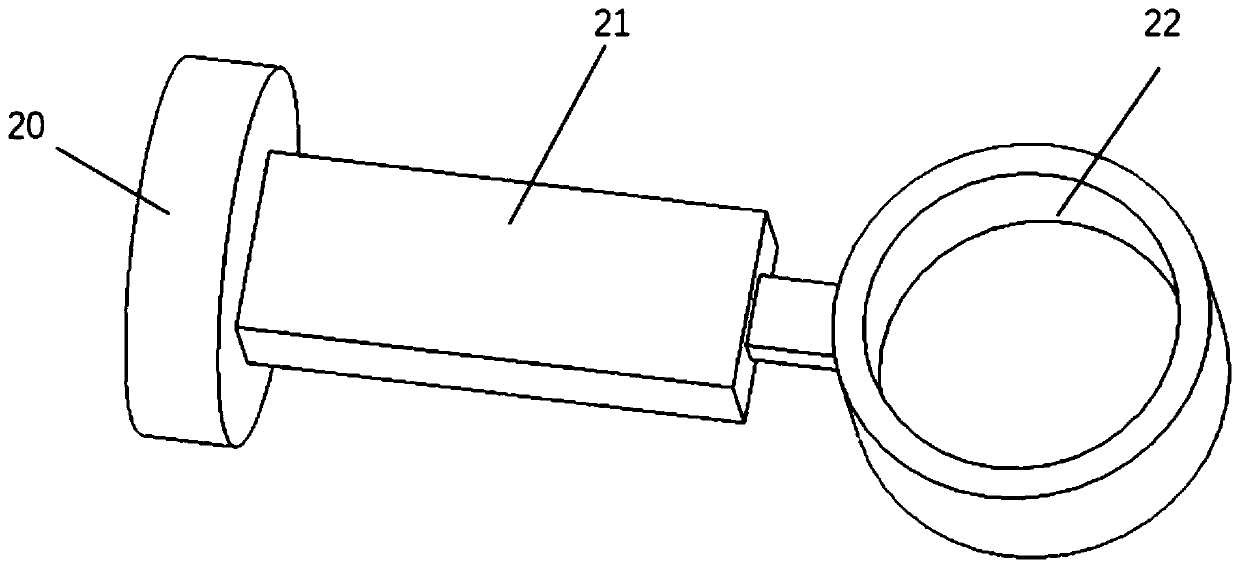

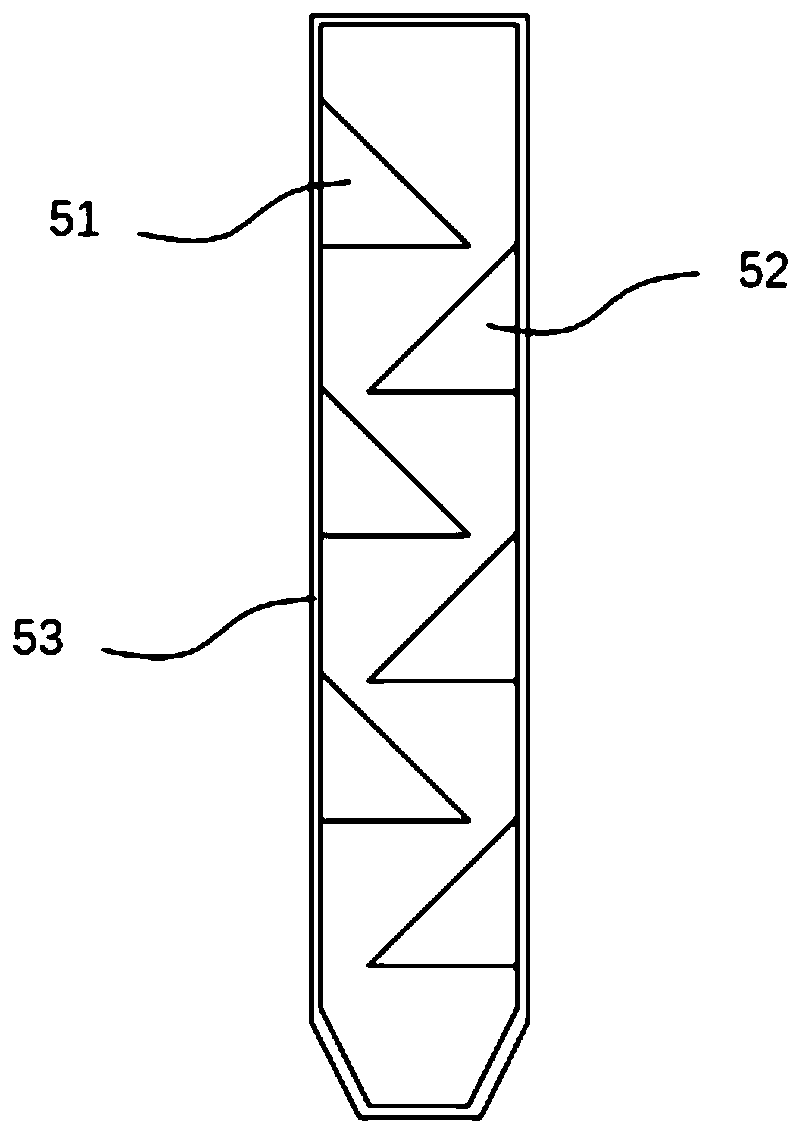

[0074] This specific implementation mode is to realize online detection of various parameters of machine-made sand, improve the precision of machine-made sand detection by image method, and provide a kind of machine-made sand quality detection equipment, such as figure 1 As shown, comprise frame, this frame is provided with feed inlet 10, water content detection device, sampling device, powder content detection device, dispersing device, imaging device and recovery device 80; Among the present embodiment, imaging device comprises The image acquisition device, the image analysis device, and the image analysis device are arranged in the host computer 70 .

[0075] The feed inlet 10 is arranged on the top of the machine frame for feeding machine-made sand. The feeding port 10 sends the machine-made sand into the water content detection device, and is sent to the powder content detection device after passing through the sampling device, and is sent to the image acquisition area of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com