Cleaning device of ultrahigh-voltage tension insulator string

A technology for strain insulator strings and cleaning devices, applied in the direction of insulators, suspension/strain insulators, detergent compositions, etc., can solve the problems of low convenience, safety, and low cleaning efficiency, and achieve manpower saving and automation High, guaranteed cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

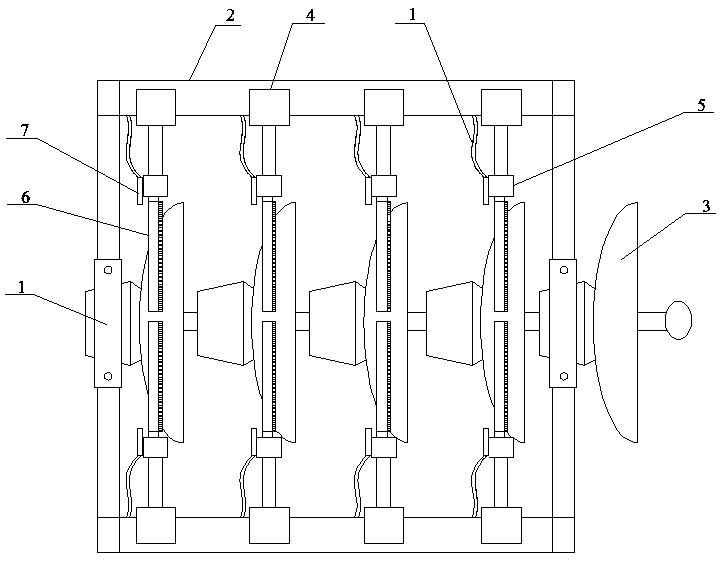

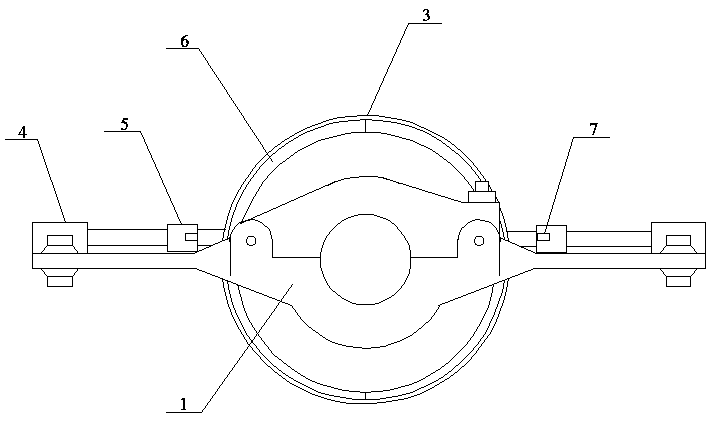

[0026] Such as figure 1 As shown, a UHV tension insulator string cleaning device includes a support mechanism arranged at both ends of the insulator string and a cleaning mechanism arranged on the support mechanism, the support mechanism includes a fixing member 1 and a support rod 2, the The insulator steel caps at the two ends of the insulator string 3 are respectively provided with one said fixing piece 1, and the two ends of the two said fixing pieces 1 are respectively connected by one said support rod 2, and several said support rods 2 are provided with several Described cleaning mechanism.

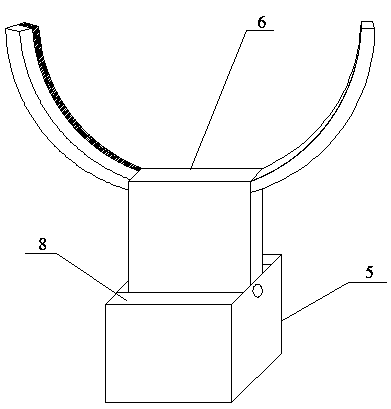

[0027] Specifically, the number of the cleaning mechanism is 4, and the cleaning mechanism includes an electric reciprocating telescopic rod 4, a connecting block 5, a semi-circular cleaning brush 6 and a cleaning nozzle 7, and the electric reciprocating telescopic rod 4 is arranged on the support On the upper side of the rod 2, the semi-circular cleaning brush 6 is arranged on the...

Embodiment 2

[0030] Such as figure 1As shown, a UHV tension insulator string cleaning device includes a support mechanism arranged at both ends of the insulator string and a cleaning mechanism arranged on the support mechanism, the support mechanism includes a fixing member 1 and a support rod 2, the The insulator steel caps at the two ends of the insulator string 3 are respectively provided with one said fixing piece 1, and the two ends of the two said fixing pieces 1 are respectively connected by one said support rod 2, and several said support rods 2 are provided with several Described cleaning mechanism.

[0031] Specifically, the number of the cleaning mechanism is 4, and the cleaning mechanism includes an electric reciprocating telescopic rod 4, a connecting block 5, a semi-circular cleaning brush 6 and a cleaning nozzle 7, and the electric reciprocating telescopic rod 4 is arranged on the support On the upper side of the rod 2, the semi-circular cleaning brush 6 is arranged on the ...

Embodiment 3

[0036] The UHV tension insulator string cleaning device in this embodiment of the present invention is different from Embodiments 1 and 2 in that: one end of the connecting block 5 is provided with an internal thread hole, and the other end is provided with a groove, and a pin is arranged in the groove shaft, the semi-annular cleaning brush is hinged to the pin shaft, and limit blocks are arranged on both sides of the pin shaft;

[0037] The support rod 2 is a hollow rod body, and the support rod 2 is filled with a cleaning agent. A water pump is arranged on the support rod 2. The water pump pumps the cleaning agent and communicates with the cleaning nozzle 7 through a conduit.

[0038] In the UHV strain insulator string cleaning device according to the embodiment of the present invention, the connection block is screwed to the electric reciprocating telescopic rod, and the other end of the connection block is hinged to the semi-circular cleaning brush, so that the semi-circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com