Refrigerator odor-removing composition and preparation method thereof

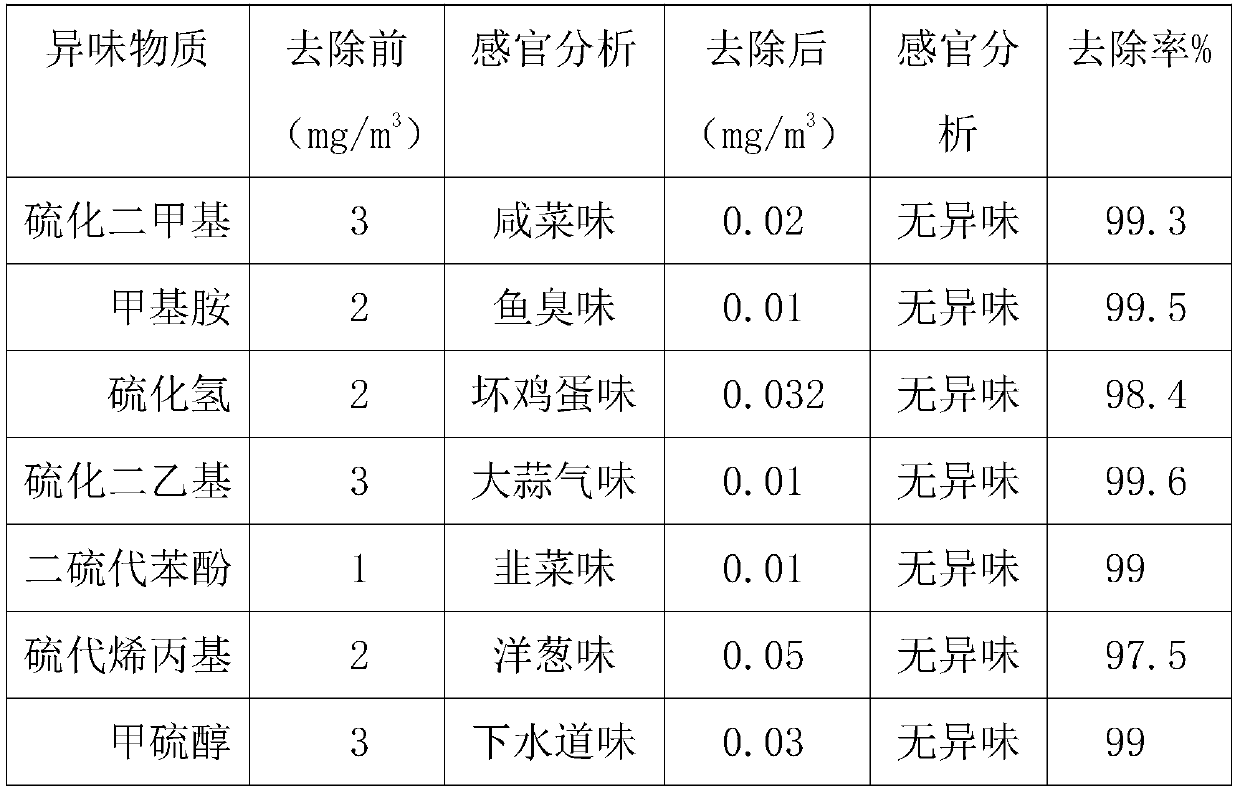

A composition and peculiar smell technology, applied in the field of kitchen and bathroom products, can solve the problems of bad smell, peculiar smell, influence on sensory perception and safety of stored food, etc., and achieve the effects of simple method, elimination of peculiar smell, and good effect of removing peculiar smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A preparation method of a refrigerator odor removal composition, the preparation method of the refrigerator odor removal composition is:

[0037] Step 1: Raw material selection: mix 12-16 parts of mixed rubber, 20-28 parts of basic magnesium hypochlorite, 5-7 parts of composite ceramic powder and 6-8 parts of silicone rubber, and weigh the materials;

[0038] Step 2: Mixing of raw materials: adopt mechanical mixing method, use a double-roller kneader, the motor speed of the two-roller kneader is 3200r / min, the mixing time is 10min, the temperature during mixing is 50℃~70℃, mix evenly After the material, use a pressing plate to repeatedly compress the powder, shape it, and let it stand for 20 minutes for natural cooling;

[0039] Step 3: Adding ingredients: The ingredients are: 20-35 parts of calcium carbonate powder. After weighing the materials, carry out mechanical mixing. The mixing time is 15 minutes. The temperature during mixing is 60°C-80°C. After continuing to ...

Embodiment

[0044] Step 1: Selection of raw materials: Proportioning 16 parts of mixed rubber, 28 parts of basic magnesium hypochlorite, 7 parts of composite ceramic powder and 6 parts of silicone rubber, and weighing the materials;

[0045] Step 2: Mixing of raw materials: adopt mechanical mixing method, use a double-roller mixer, the speed of the motor of the double-roller mixer is 3200r / min, the mixing time is 10min, the temperature during mixing is 65°C, and the material is mixed evenly. Use a pressing plate to repeatedly compress the powder, shape it, and let it stand for 20 minutes for natural cooling;

[0046] Step 3: Adding ingredients: The ingredients are: 31 parts of calcium carbonate powder. After weighing the materials, carry out mechanical mixing. The mixing time is 15 minutes, and the temperature during mixing is 75°C. The generation of white smoke can be stopped, and it is allowed to cool after being tiled again;

[0047] Step 4: Adding auxiliary materials: The auxiliary m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com