Sludge centrifugal dewatering equipment and using method

A centrifugal dehydration and sludge technology, applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc., can solve the problems of long treatment cycle, difficult to move, complicated equipment, etc., to facilitate replacement and maintenance, speed up Water filtration process, the effect of improving feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

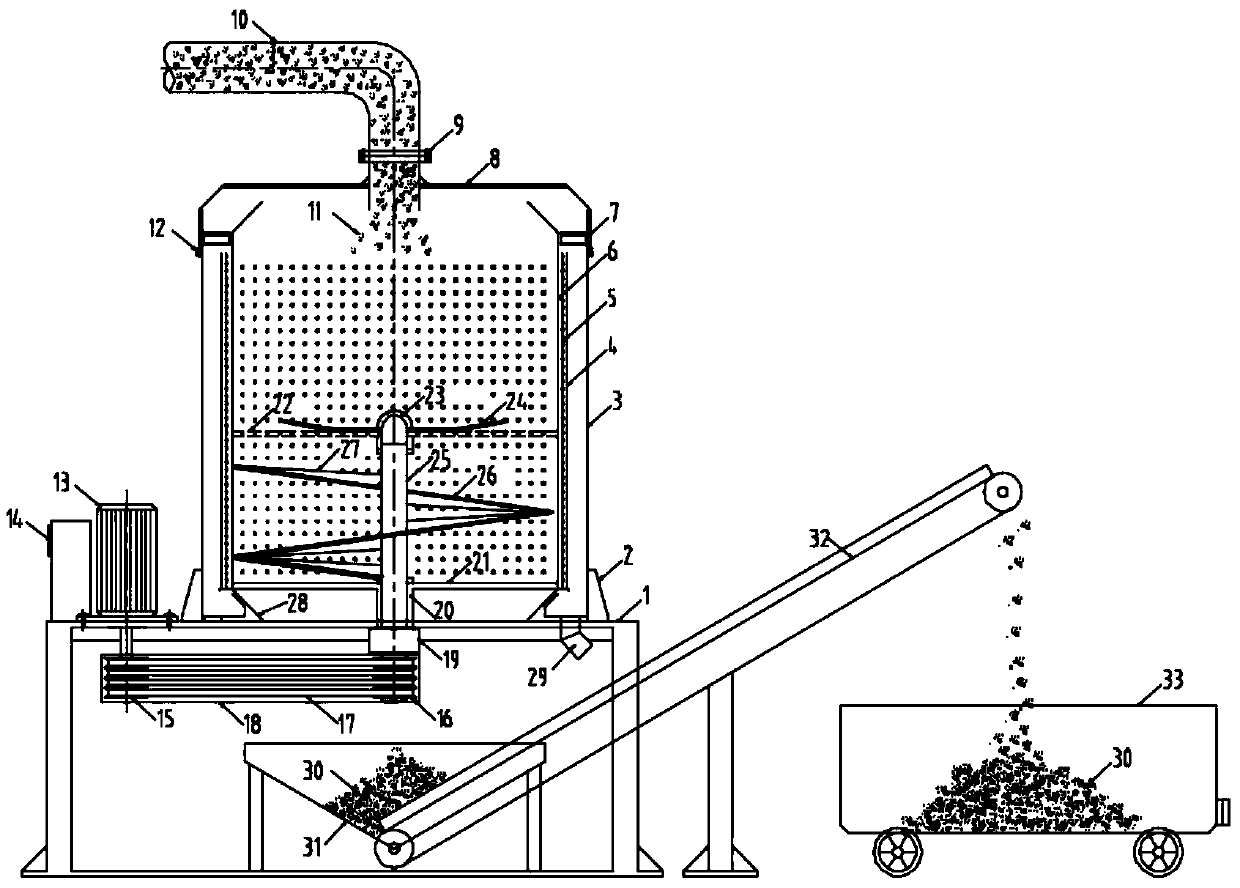

[0036] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, they are only examples, and at the same time, the advantages of the present invention will become clearer and easier to understand.

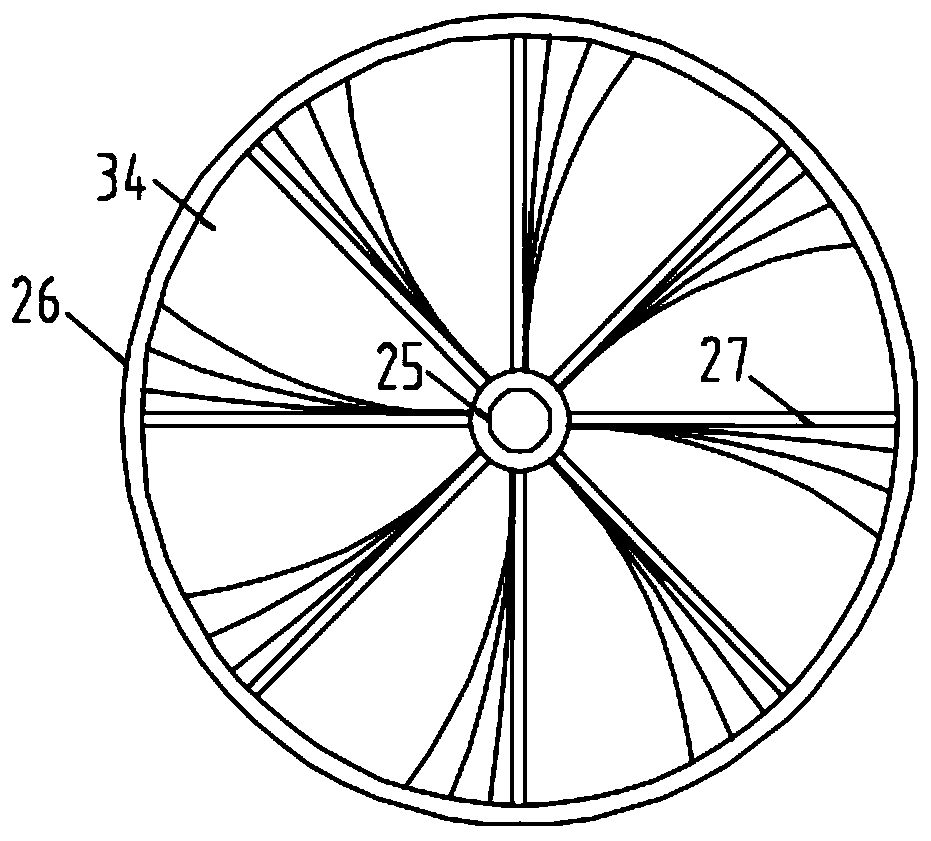

[0037] refer to Figure 1-2Shown: a sludge centrifugal dewatering equipment, which includes a machine base 1, a fixed ring 2, a water collection bucket 3, an outer filter bucket 4, a middle geotechnical filter 5, an inner filter bucket 6, a balance ring 7, a top cover 8, Flange 9, imported pumping steel pipe 10, dredging material 11, lock 12, motor 13, control cabinet 14, drive wheel 15, transmission wheel 16, transmission belt 17, transmission protection cover 18, electromagnetic clutch 19, filter bucket shaft 20. Lower connecting rod 21, upper connecting rod 22, spherical steel cover 23, tray 24, spiral scraper shaft 25, spiral scraper 26, spiral co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com