Preparation method of calcium hydroxide powder with high reactivity and high specific surface area

A technology of high specific surface area and calcium hydroxide, applied in the direction of calcium/strontium/barium oxide/hydroxide, etc., can solve the problems of small specific surface area and inability to effectively purify flue gas, and achieve high specific surface area and high reaction Sexuality and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

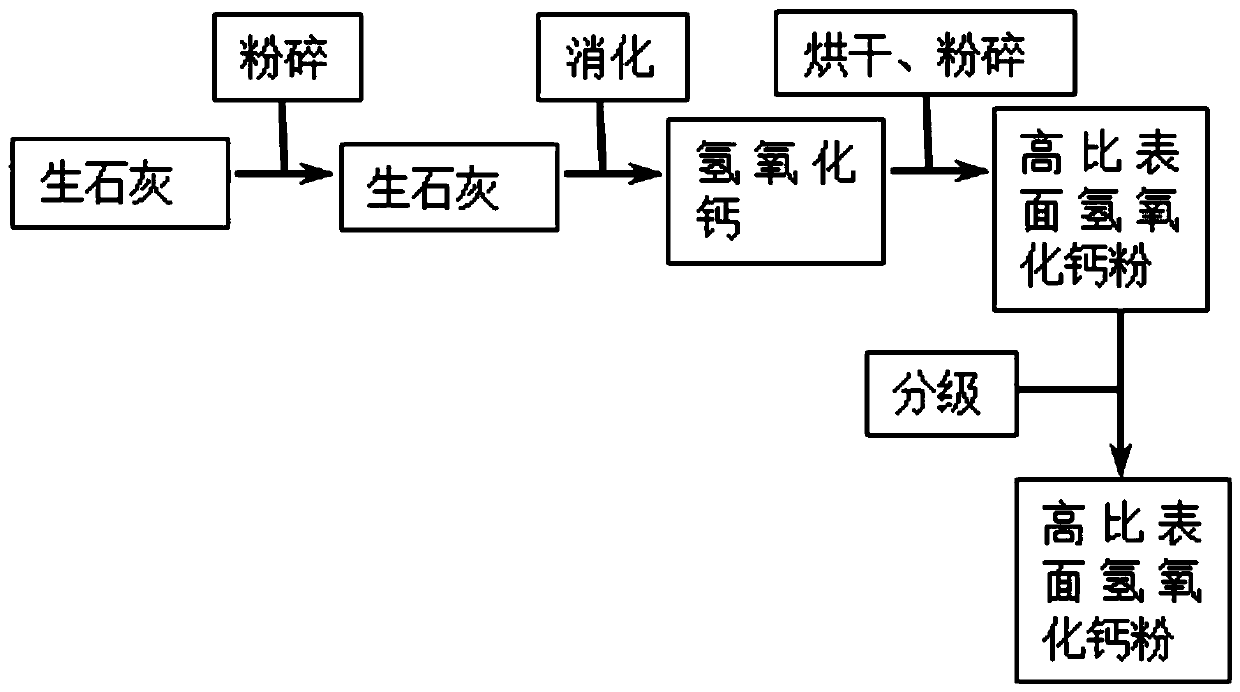

[0021] see figure 1 , a preparation method of calcium hydroxide powder with high reactivity and high specific surface area, comprising the following steps:

[0022] (1) Pulverization: Pulverize the calcined quicklime, and the particle size of the pulverized quicklime is controlled at 300-1000 mesh;

[0023] (2) Digestion: Digest the crushed quicklime; first add 4~7% propylene glycol and 2~4% triethanolamine to the digestion water, and then use a premixed water-material ratio of 0.55~0.70 The machine mixes quicklime and digestion water and enters the digester; the stirring speed of the digester is 700 rpm-800 rpm, the outlet temperature of the digester is 90°C, and the digestion time is 9-12min; The pressure of the cut-off point of the water used is controlled at 2 bar G, and the fluctuation is 0.3 bar; in the digester, lime reacts with water to produce slaked lime, and its chemical equation is below 350°C:

[0024] CaO+H 2 O→Ca(OH) 2 +276 (kcal / kg CaO);

[0025] (3) Dryin...

Embodiment 1

[0030] A preparation method of calcium hydroxide powder with high reactivity and high specific surface area, comprising the following steps:

[0031] (1) Pulverization: Pulverize the calcined quicklime, and the particle size of the pulverized quicklime is controlled at 300-1000 mesh;

[0032] (2) Digestion: Digest the crushed quicklime, and control the content of quicklime for digestion at 91~96%; first add 5.5% propylene glycol and 2.5% triethanolamine to the digestion water, and then use the water-material ratio of 0.6 Ratio, use a pre-mixer to mix quicklime and digestion water, and enter the digester; the stirring speed of the digester is 750 rpm, the outlet temperature of the digester is 90°C, and digest for 10 minutes; the water temperature of the digestion water is controlled at 90°C throughout the process, and the The pressure at the cut-off point is controlled at 2bar G, with a fluctuation of 0.3bar; in the digester, lime reacts with water to produce slaked lime. Below...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com