Parallel and continuous preparation method for biodegradable resin

A technology of biodegradable resin and ester compound, applied in the field of polymer polymer resin, can solve the problems of sustainable development of human beings that affect the environment, difficult to decompose, etc., and achieve significant environmental and social benefits, good economic benefits, and flexible and diverse products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

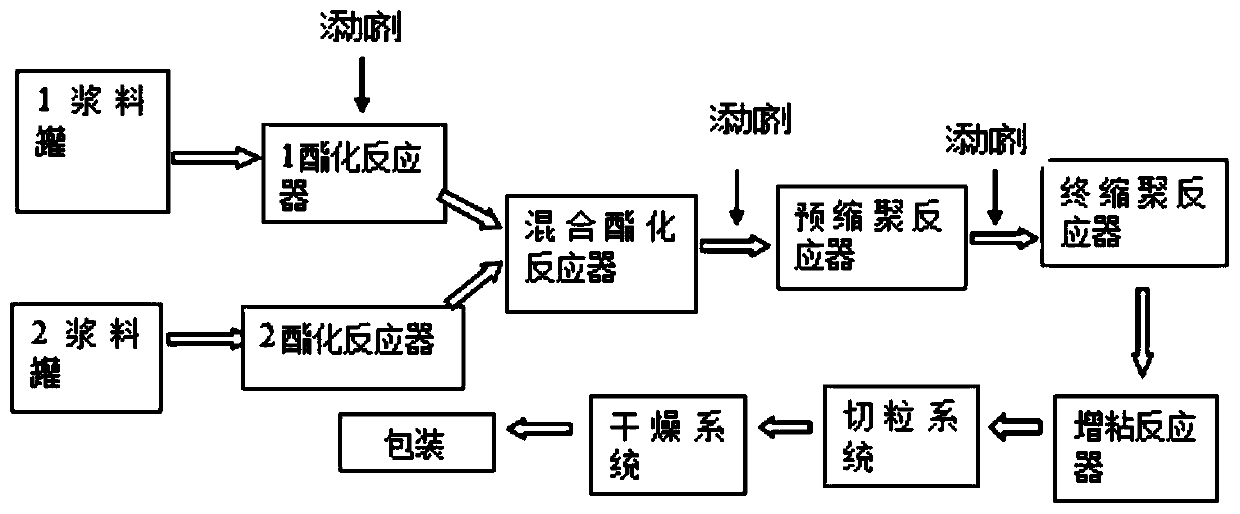

[0037] Such as figure 1 As shown, a method for preparing biodegradable resins in parallel, in which terephthalic acid (PTA) and 1,4-butanediol are prepared in a slurry tank at a molar ratio of 1:1.6 to make a slurry, which is passed through a delivery pump Send it into an esterification reactor at a flow rate of 681kg / H for esterification. The esterification temperature is controlled at 235°C and the pressure is controlled at an absolute pressure of 75kPa. During the esterification, 0.2kg of tetrabutyl titanate is continuously added to carry out The esterification reaction rate reaches over 92%;

[0038] In addition, at the same time, adipic acid and 1,4-butanediol are prepared into a slurry in the 2 slurry tank at a molar ratio of 1:1.4, which is sent to the 2 esterification reaction by a delivery pump at a flow rate of 745kg / H The esterification is carried out in the vessel, the esterification temperature is controlled at 180°C, the pressure is controlled at an absolute pre...

Embodiment 2

[0044] Such as figure 1 As shown, a method for preparing biodegradable resins in parallel, in which terephthalic acid (PTA) and 1,4-butanediol are prepared in a slurry tank at a molar ratio of 1:1.6 to prepare a slurry, which is passed through a delivery pump Send it into an esterification reactor at a flow rate of 650kg / H for esterification. The esterification temperature is controlled at 235°C and the pressure is controlled at an absolute pressure of 75kPa. During the esterification, 0.2kg of tetrabutyl titanate is continuously added to carry out The esterification reaction rate reaches over 92%;

[0045] In addition, at the same time, succinic acid and 1,4-butanediol are prepared into a slurry in the 2 slurry tank at a molar ratio of 1:1.6, which is sent to the 2 esterification reaction by a delivery pump at a flow rate of 800kg / H Esterification is carried out in the vessel, the esterification temperature is controlled at 145°C, the pressure is controlled at an absolute pr...

Embodiment 3

[0051] Such as figure 1 As shown, a method for preparing biodegradable resins in parallel and continuously, succinic acid (SA) and 1,4-butanediol are prepared into a slurry in a slurry tank at a molar ratio of 1:1.6, and the slurry is fed through a delivery pump to The flow rate of 1000kg / H is sent to 1 esterification reactor for esterification. The esterification temperature is controlled at 145°C and the pressure is controlled at an absolute pressure of 75kPa. During the esterification, 0.2kg of tetrabutyl titanate is continuously added to perform esterification. The chemical reaction rate reaches more than 92%;

[0052] In addition, at the same time, adipic acid and 1,4-butanediol are prepared into a slurry in the 2 slurry tank at a molar ratio of 1:1.4, which is sent to the 2 esterification reaction at a flow rate of 350kg / H through a delivery pump. Esterification is carried out in the vessel, the esterification temperature is controlled at 180°C, the pressure is controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com