Environmentally friendly and long-life gasoline engine oil and its production process

A gasoline engine oil and production process technology, applied in the field of gasoline engine oil, can solve problems such as excessive heat, shorten oil life, increase oil viscosity and total acid value sludge, achieve simple production process, ensure extreme performance, and increase mileage and durability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

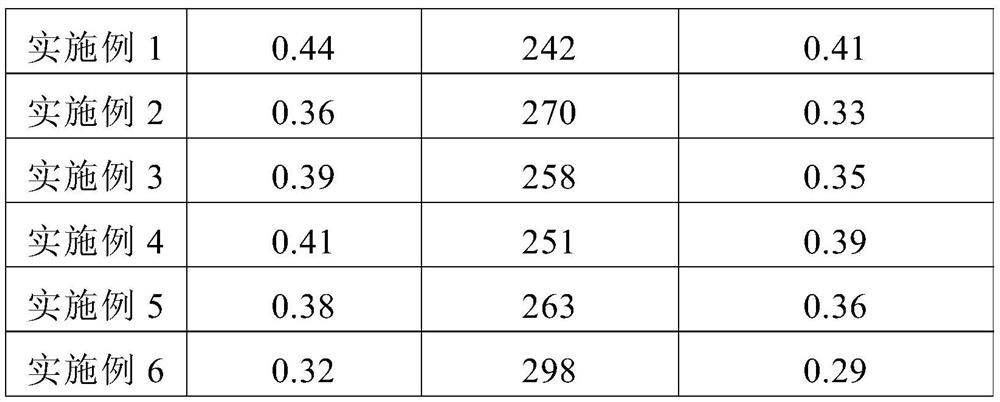

Examples

Embodiment 1

[0028] The production technology of environment-friendly long-life gasoline engine oil comprises the following steps:

[0029](1) Take 20 parts by weight of polyalphaolefin base oil, 45 parts by weight of 150N base oil, and 35 parts by weight of 100N base oil at a speed of 300r / min and stir for 20min to obtain a mixed base oil;

[0030] (2) Heat the mixed base oil to 70°C, add 9 parts by weight of viscosity index improver, 7.2 parts by weight of detergent and dispersant, 0.5 part by weight of pour point depressant, 0.9 part by weight of antioxidant, 1 part by weight of antiwear agent, 0.3 The parts by weight of the antifoaming agent were stirred for 40 minutes at a speed of 300 r / min to obtain an environmentally friendly long-life gasoline engine oil.

[0031] The viscosity index improver is a hydrogenated styrene diene copolymer.

[0032] The detergent and dispersant is borated polyisobutylene bis-succinimide.

[0033] The antioxidant is prepared by mixing 2,6-di-tert-butyl...

Embodiment 2

[0038] The production technology of environment-friendly long-life gasoline engine oil comprises the following steps:

[0039] (1) Take 20 parts by weight of polyalphaolefin base oil, 45 parts by weight of 150N base oil, and 35 parts by weight of 100N base oil at a speed of 300r / min and stir for 20min to obtain a mixed base oil;

[0040] (2) Heat the mixed base oil to 70°C, add 9 parts by weight of viscosity index improver, 7.2 parts by weight of detergent and dispersant, 2 parts by weight of functionalized silica, 0.5 parts by weight of pour point depressant, and 0.9 parts by weight of antioxidant , 1 part by weight of anti-wear agent, 0.3 part by weight of defoamer and stirring for 40 min with a rotating speed of 300 r / min to obtain an environmentally friendly long-life gasoline engine oil.

[0041] The viscosity index improver is a hydrogenated styrene diene copolymer.

[0042] The detergent and dispersant is borated polyisobutylene bis-succinimide.

[0043] The functiona...

Embodiment 3

[0049] The production technology of environment-friendly long-life gasoline engine oil comprises the following steps:

[0050] (1) Take 20 parts by weight of polyalphaolefin base oil, 45 parts by weight of 150N base oil, and 35 parts by weight of 100N base oil at a speed of 300r / min and stir for 20min to obtain a mixed base oil;

[0051] (2) Heat the mixed base oil to 70°C, add 9 parts by weight of viscosity index improver, 7.2 parts by weight of detergent and dispersant, 2 parts by weight of functionalized silica, 0.5 parts by weight of pour point depressant, and 0.9 parts by weight of antioxidant , 1 part by weight of anti-wear agent, 0.3 part by weight of defoamer and stirring for 40 min with a rotating speed of 300 r / min to obtain an environmentally friendly long-life gasoline engine oil.

[0052] The viscosity index improver is a hydrogenated styrene diene copolymer.

[0053] The detergent and dispersant is borated polyisobutylene bis-succinimide.

[0054] The functiona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com