A kind of recycled wear-resistant deformed aluminum alloy and its preparation method

A technology of aluminum alloy and aluminum alloy sheet, which is applied in the field of regenerated wear-resistant deformed aluminum alloy and its preparation, can solve the problems that it is difficult to take into account the wear resistance and hot cracking tendency of 6000 series aluminum alloy, and the hardness and wear resistance are low. Significant aging strengthening effect, improved mechanical properties, and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

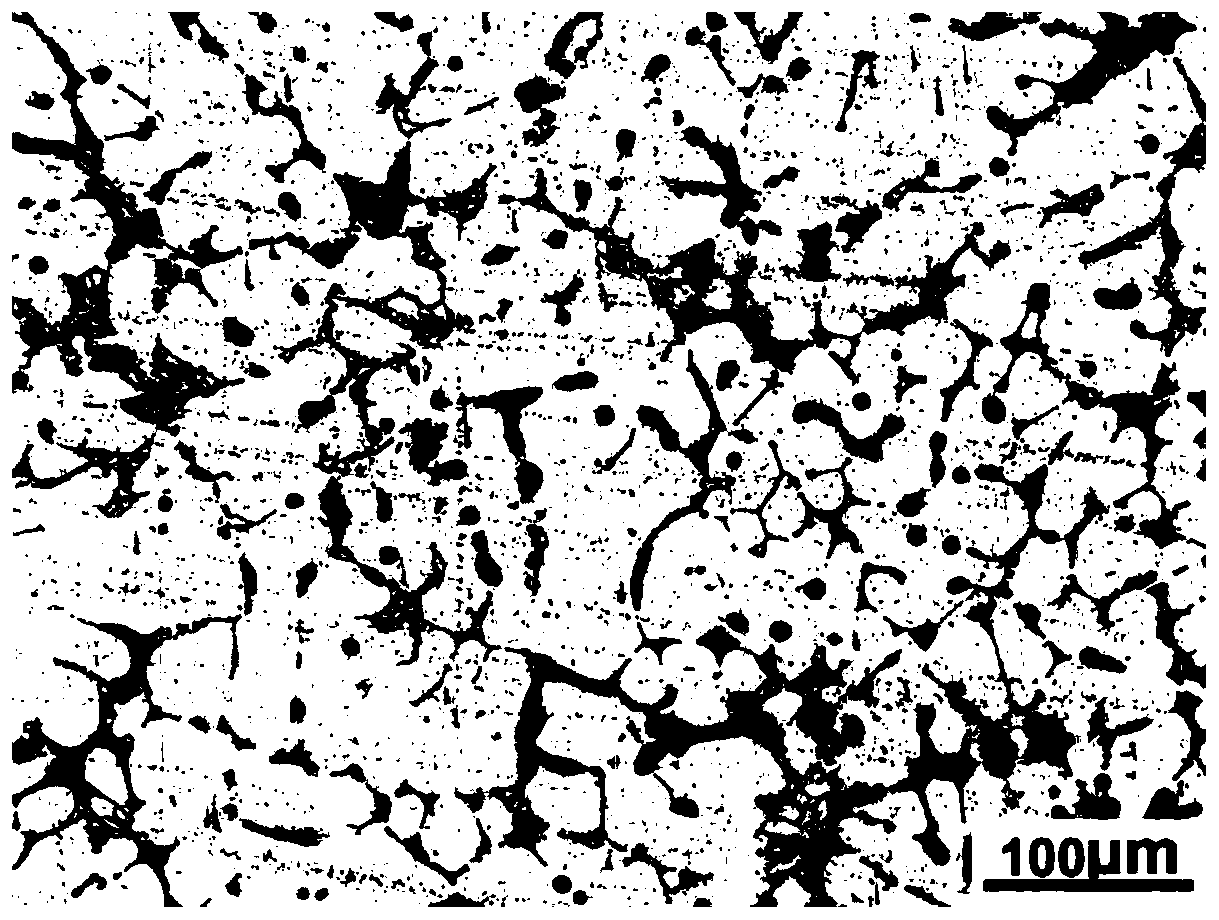

[0059] In this example, on the basis of comparative examples, the components of the 6000-series secondary aluminum alloy melts are controlled, and the raw materials used for the control include: Al-20%Mn, Al-50%Mg, Al-10%RE and Al-10 %Sr master alloy, wherein RE is a mixed rare earth containing Ce and La (Ce / La mass ratio is 6 / 4). The composition and mass percentage of the alloy are: Fe: 1.1%, Si: 0.8%, Mn: 0.8%, Mg: 1.2%, Cu: 0.7%, Zn: 0.25%, RE: 0.2%, Sr: 0.05%, Yu The amount is Al.

[0060] The smelting and preparation process of the alloy in this embodiment includes the following steps: smelting of scrap aluminum alloy, alloy composition adjustment, casting molding, homogenization heat treatment, rolling molding and solution aging treatment. Compared with the comparative example, the alloy composition adjustment is increased. The specific process and process parameters are as follows:

[0061] (1) Waste miscellaneous aluminum alloy smelting: Sorting, weighing, melting, ...

Embodiment 2

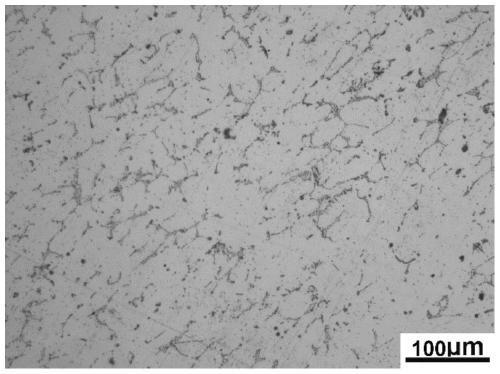

[0079] In this example, 6000x scrap aluminum alloy products are mainly selected for smelting, and the composition of the melt is adjusted. The raw materials used for adjustment include: Al-20%Mn, Al-50%Mg, Al-10%RE and Al-10% Sr master alloy. The composition and mass percentage of the alloy are: Fe: 1.2%, Si: 0.6%, Mn: 1.0%, Mg: 1.5%, Cu: 0.3%, Zn: 0.1%, RE: 0.1%, Sr: 0.08%, Yu The amount is Al.

[0080] The melting and preparation process of the alloy in this embodiment is the same as that in Embodiment 1. The different specific process parameters are different. The specific process and process parameters are as follows:

[0081] (1) Waste miscellaneous aluminum alloy smelting: Sorting, weighing, melting, and then performing melt refining treatment for 6000 series waste miscellaneous aluminum alloy products. Refining and slag removal were carried out by adding refining agent and slag removal agent by nitrogen injection method, the treatment temperature was controlled at 6...

Embodiment 3

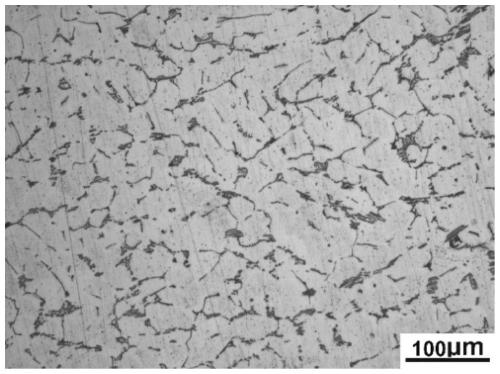

[0090] In this embodiment, 6000 series waste aluminum alloy products are mainly selected for smelting, and the composition of the melt is adjusted, and the raw materials used for the adjustment are the same as those in Embodiment 1. The composition and mass percentage of the alloy are: Fe: 0.8%, Si: 1.0%, Mn: 0.6%, Mg: 1.0%, Cu: 0.7%, Zn: 0.3%, RE: 0.4%, Sr: 0.03%, Yu The amount is Al.

[0091] The melting and preparation process of the alloy in this embodiment is the same as that in Embodiment 1. The different specific process parameters are different. The specific process and process parameters are as follows:

[0092] (1) Waste miscellaneous aluminum alloy smelting: Sorting, weighing, melting, and then performing melt refining treatment for 6000 series waste miscellaneous aluminum alloy products. Refining and slag removal were carried out by adding refining agent and slag removal agent by nitrogen injection method, the treatment temperature was controlled at 720°C, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com