Friction experiment device for friction performance test of cutting tool coating

A friction performance and experimental device technology, applied in the direction of measuring devices, testing wear resistance, strength characteristics, etc., can solve the problems of difficult management of devices, limited friction duration, inability to provide tribological phenomena, etc., to achieve non-deformation and high rigidity , to achieve the effect of heavy load friction experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention is described in detail below in conjunction with accompanying drawing description:

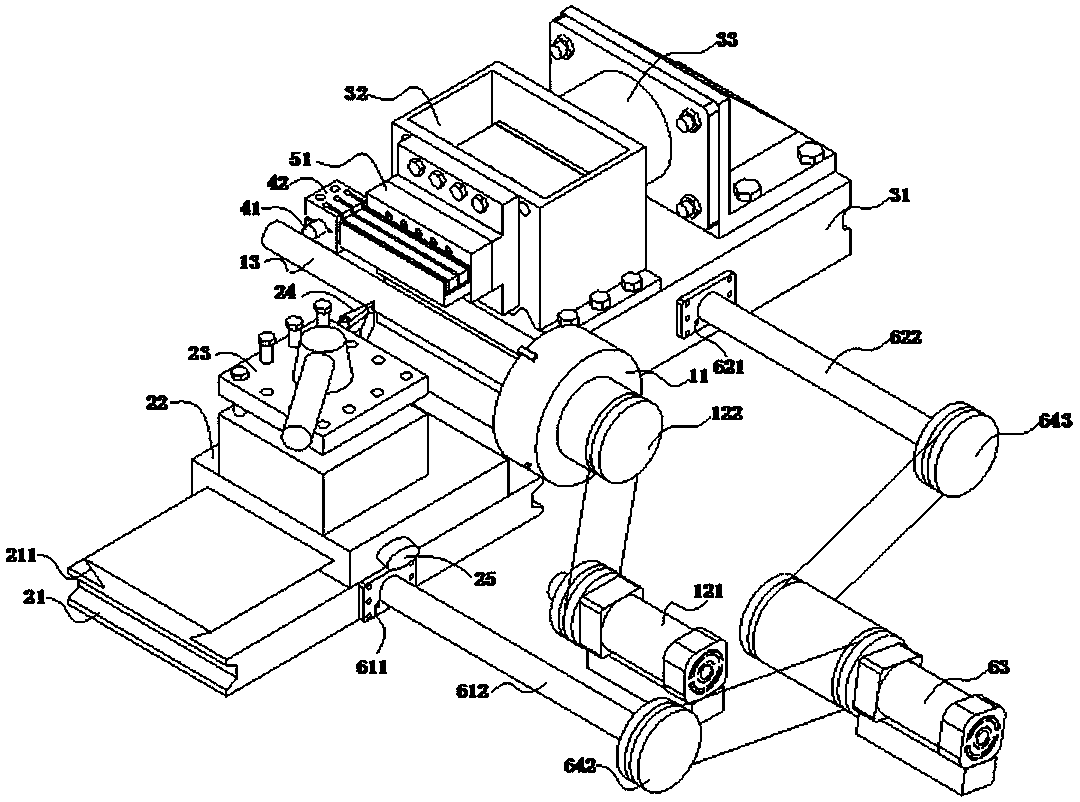

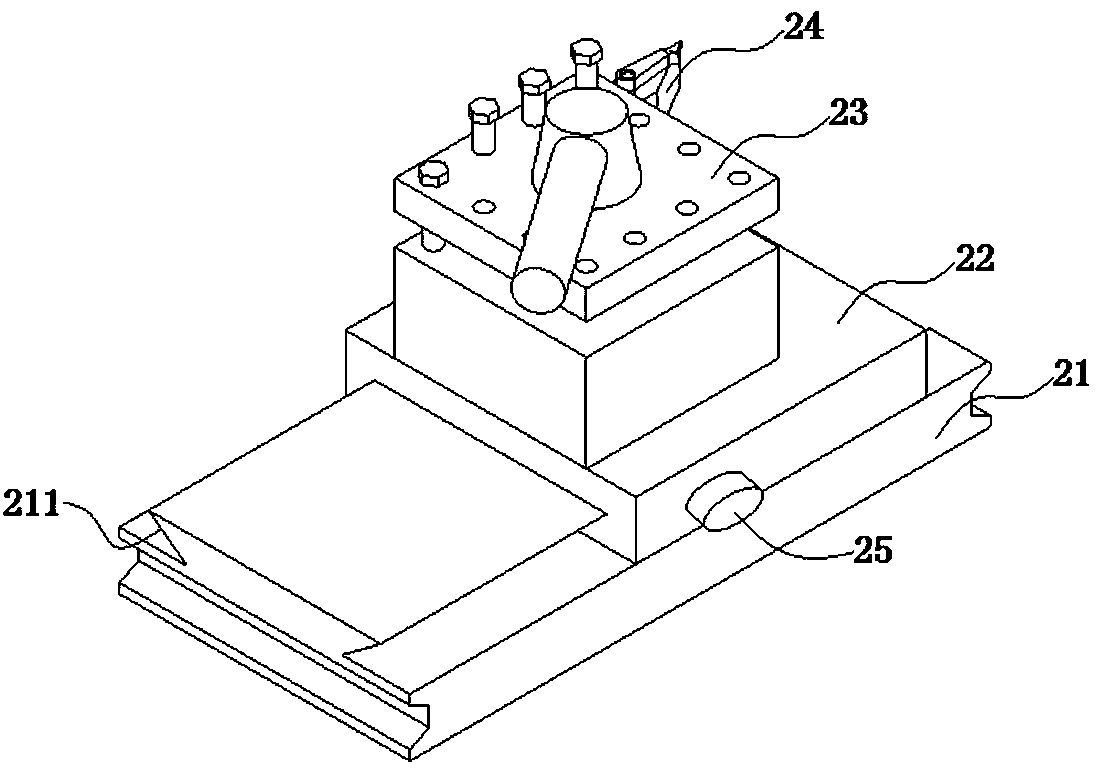

[0045] Such as figure 1As shown, the present invention includes a rotary fixing mechanism for providing rotational power for the columnar workpiece 13, a cutting mechanism for cutting the surface of the columnar workpiece 13, a pressure regulating mechanism for providing and adjusting the experimental pressure, and a friction mechanism for friction experiments. , a data collection mechanism for data collection and analysis, and a feed action mechanism for providing relative feed movement of the columnar workpiece 13;

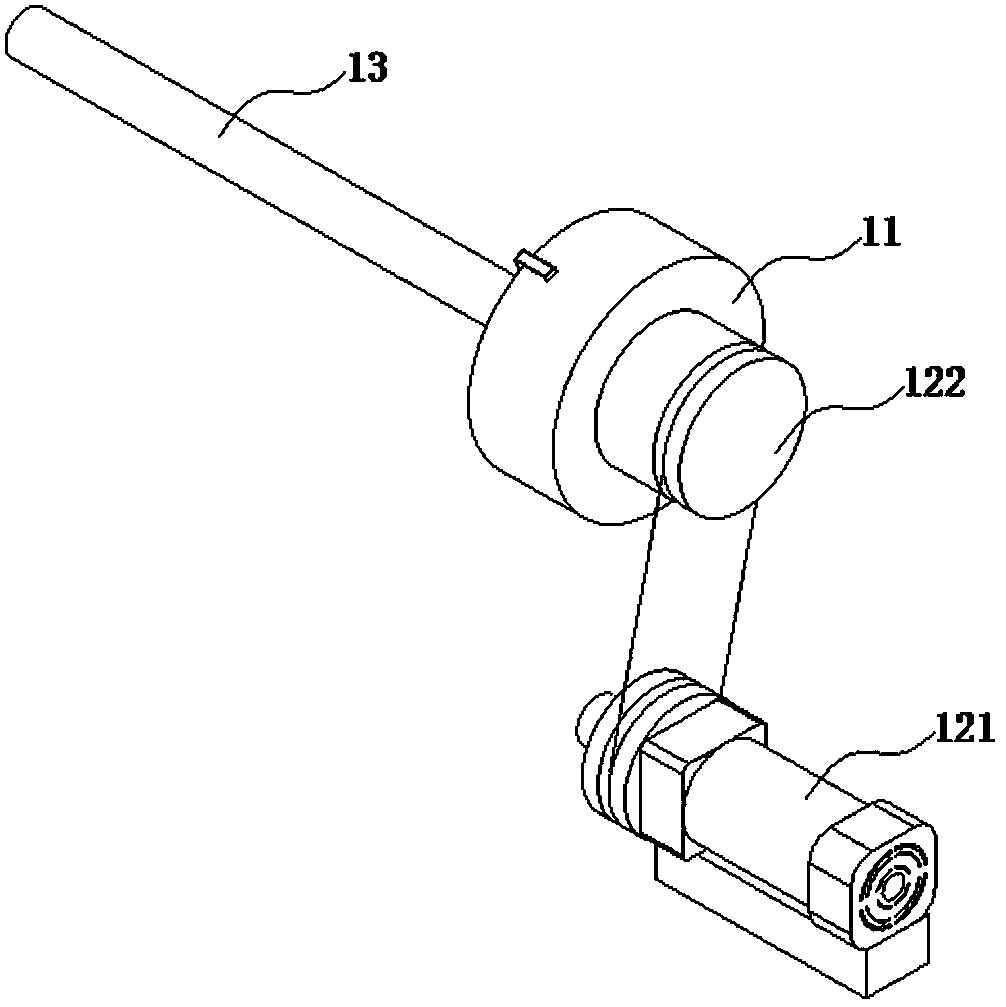

[0046] Such as figure 2 As shown, the rotation fixing mechanism includes a three-jaw chuck 11, a first driving device for driving the three-jaw chuck 11 to rotate in a circumferential direction, and a cylindrical workpiece 13 fixedly installed on the three-jaw chuck 11 and used for friction experiments; The first driving device includes a first dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com