Directional emission organic semiconductor light emitting diode array based on metal nano electrodes and preparation thereof

A technology of electroluminescent devices and organic semiconductors, which is applied in the field of OLED arrays, can solve the problems of insufficient attention to the emission directionality of the device, and the failure to obtain optimization effects, etc., and achieve good directional emission characteristics, improved light extraction efficiency, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

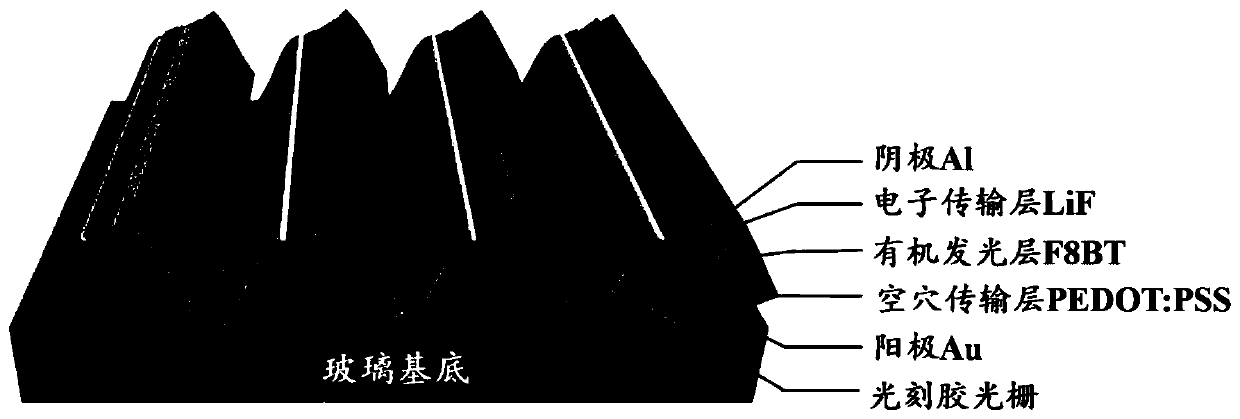

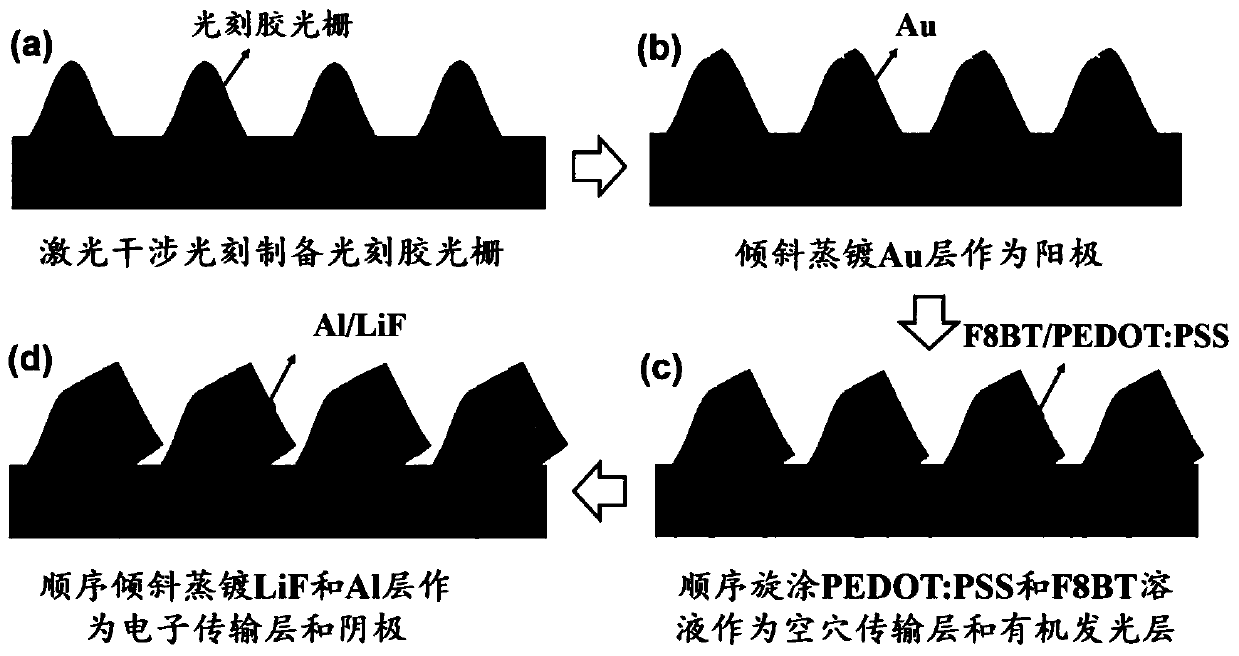

[0022] (1), the selected size is 2×2cm 2 The glass is used as the substrate, and after repeated cleaning, it is etched with high-power oxygen plasma for 5-10 minutes to completely remove the organic matter on the substrate. Then, spin-coat S1805 photoresist on the substrate at a rotational speed of 3000 rpm for 30 seconds. Prepare a photoresist film with a thickness of about 200 nm. The samples were then placed on a heating plate and heated at 110 °C for 90 s. Then use the 343nm laser interference optical path to expose the sample, and after development, a photoresist grating structure with a period of 500nm and a modulation depth of about 180nm can be obtained, such as figure 2 (a).

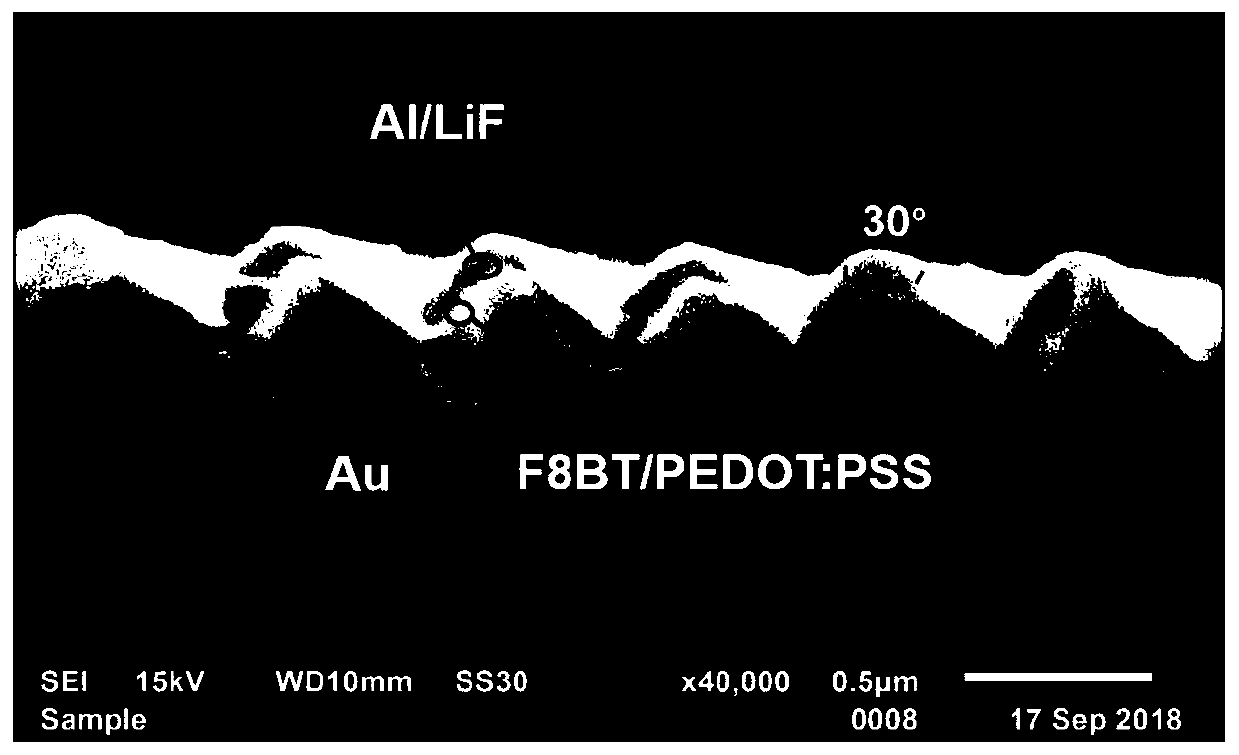

[0023] (2) The grid line of the photoresist grating is used as the template for preparing the nanoscale organic electroluminescent device. Deposit an Au layer on one side of the grating as an anode using oblique evaporation technology, such as figure 2 (b). The thickness of the Au thin f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com