Cylindrical container and method for producing same

A manufacturing method and tubular technology, applied in containers, rigid containers, packaging, etc., can solve the problems of poor appearance, wrinkles, etc., and achieve the effects of efficient manufacturing, smooth external insertion, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0051] Hereinafter, the first embodiment of the present invention will be described in detail with reference to the drawings. In addition, this invention is not limited to the following embodiment, and is interpreted.

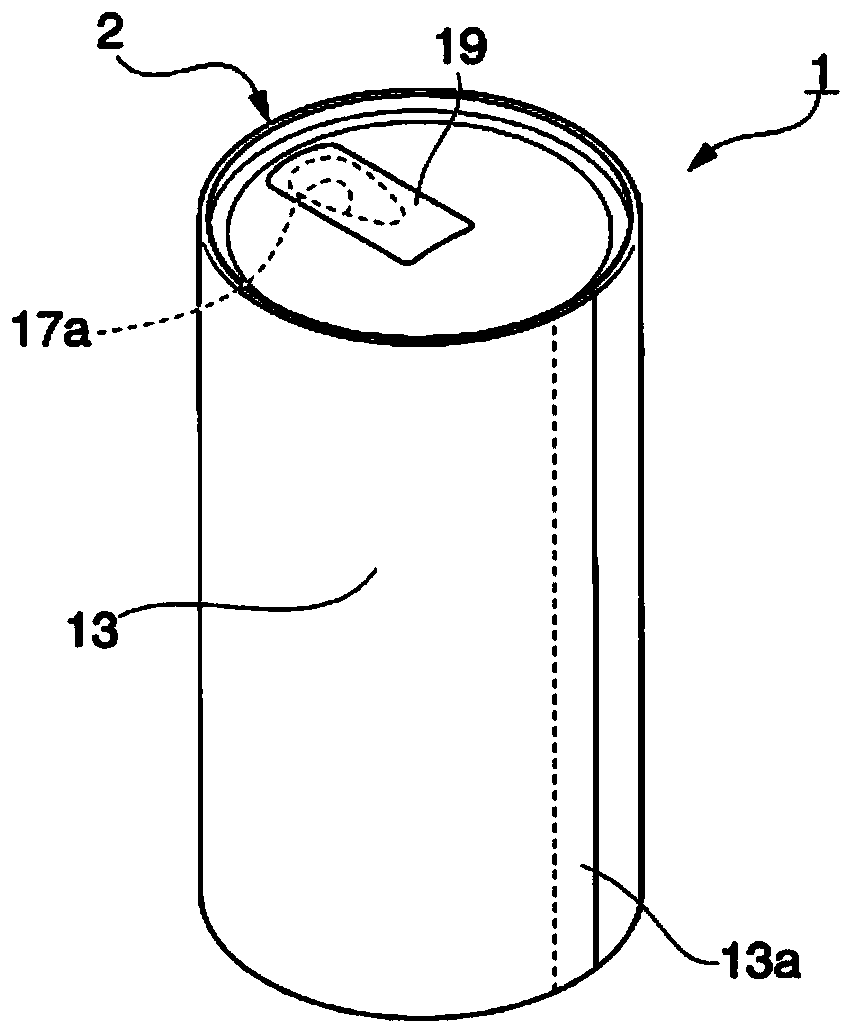

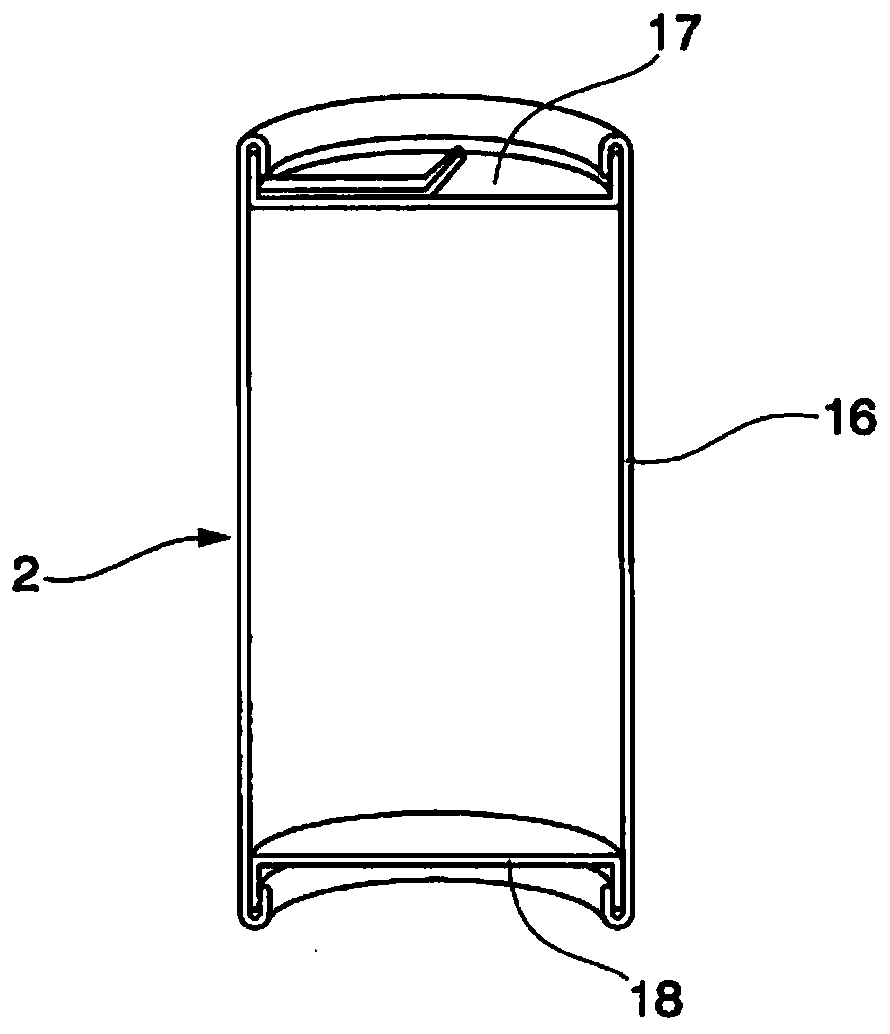

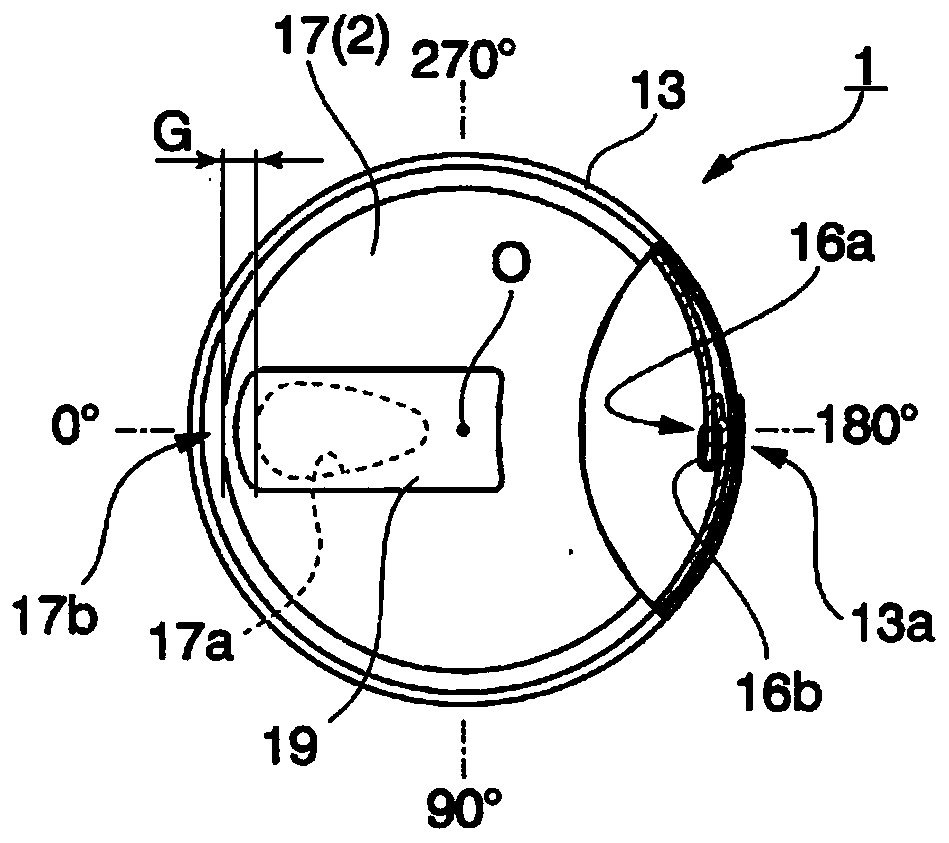

[0052] figure 1 It is a perspective view showing the cylindrical container of this embodiment. figure 2 It is a longitudinal sectional view of the cylindrical container of this embodiment. In addition, image 3 It is a partial cross-sectional plan view of the cylindrical container of the present embodiment viewed from above, Figure 4 It is a schematic cross-sectional view showing an example of the laminated material constituting the main body of the cylindrical container. In the present embodiment, the plan view refers to a view viewed from the direction of the central axis O of the main body, which will be described later.

[0053] Such as figure 1 As shown, the cylindrical container 1 has: a cylindrical container main body 2 having a cylindrical main body por...

no. 2 approach

[0089] Next, the second embodiment of the present invention will be described. The second embodiment of the present invention does not use the hot-melt adhesive 21 and holds the main body portion 16 and the cylindrical shrink film 13. In addition, this invention is not limited to the following embodiment, and is interpreted.

[0090] The cylindrical container according to this embodiment is different from the first embodiment in that the main body portion 16 and the cylindrical shrink film 13 are not bonded with the hot-melt adhesive 21. Also used in the second embodiment Figure 1 to Figure 4 The structure shown. Regarding the same structure as that of the first embodiment, the description thereof will be omitted.

[0091] As the material of the cylindrical shrink film 13 and the second resin layer 35 of this embodiment, the same materials as those of the first embodiment can be used.

[0092] In this embodiment, the shrinkage temperature of the cylindrical shrink film 13 is high...

Embodiment

[0100] The following shows an example using the method of manufacturing the cylindrical container according to the second embodiment.

[0101]

[0102] The basis weight is 200g / m 2 On the surface of the paper, low-density polyethylene resin (LDPE) was extruded and laminated to a thickness of 50 μm to form the second resin layer. Next, the gas barrier film (barrier layer) in which aluminum oxide is vapor-deposited on a 12μm thick polyethylene terephthalate resin (PET) film and the back of the paper are extruded with LDPE (third resin layer) 45μm After lamination, the LDPE was extrusion-laminated with a thickness of 60 μm as the first resin layer on the opposite side of the paper of the gas barrier film to form a laminate. This laminated body forms a cylindrical container body of Φ48 mm. As the shrink film, use OPS film DXL-270-41S 45μ (trademark registration, made by "Mitsubishi Resin") flexible printed matter, as a solvent for film bonding, use a mixture of ethyl acetate and cyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Coating thickness | aaaaa | aaaaa |

| Shrinkage temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap