Polyalkylene carbonate-based resin film

A polyalkylene carbonate and alkylene carbonate technology, applied in the field of resin films, can solve problems such as cost increase, and achieve the effects of improving mechanical properties, excellent compatibility, and excellent elongation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] The preparation method of the polyketone resin is not particularly limited, for example, the polyketone resin is prepared by reacting carbon monoxide with a compound containing an unsaturated double bond. More recently, it can be prepared in the form of alternating copolymers in which repeat units consisting of carbon monoxide and at least one or more ethylenically unsaturated hydrocarbons are linked alternately.

[0077] The melt index (MI) of the polyketone resin may be 3-8, preferably 5-7. When the above range is satisfied, the compatibility with polyalkylene carbonate is excellent, and the processability of the film can be improved.

[0078] Preferably, the polyketone resin is an aliphatic polyketone containing ethylene, propylene, isopropylene or butylene units. It is more preferred to use the form of copolymers or terpolymers containing at least one of these repeating units.

[0079] In addition, the polyketone resin may have a weight average molecular weight of...

preparation Embodiment 1

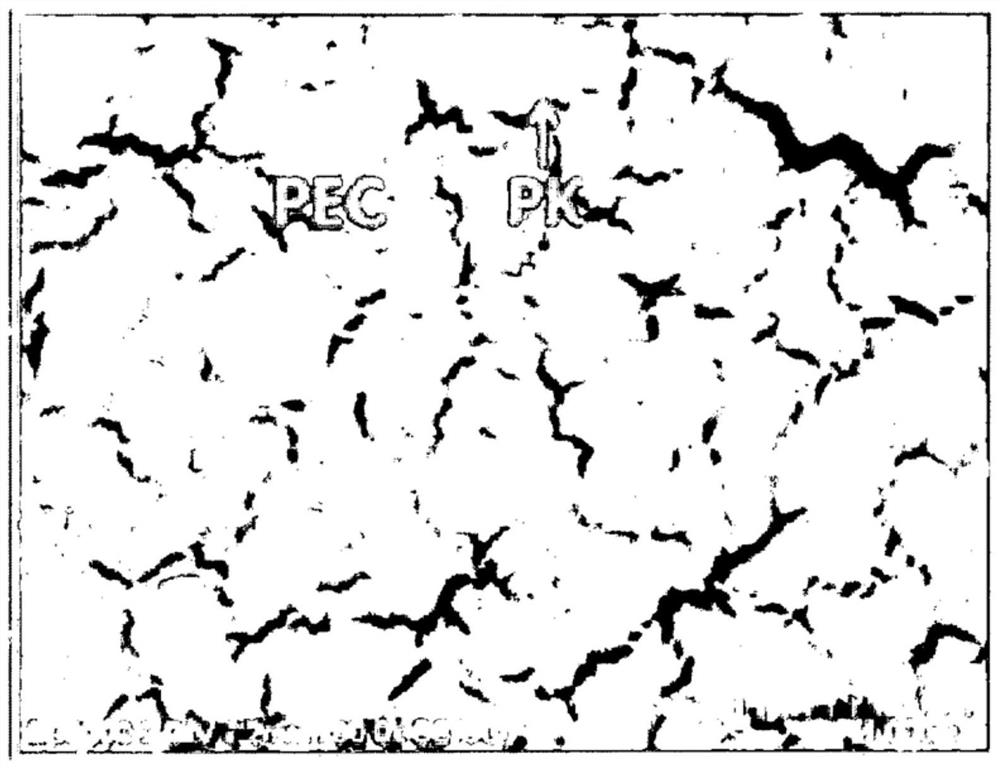

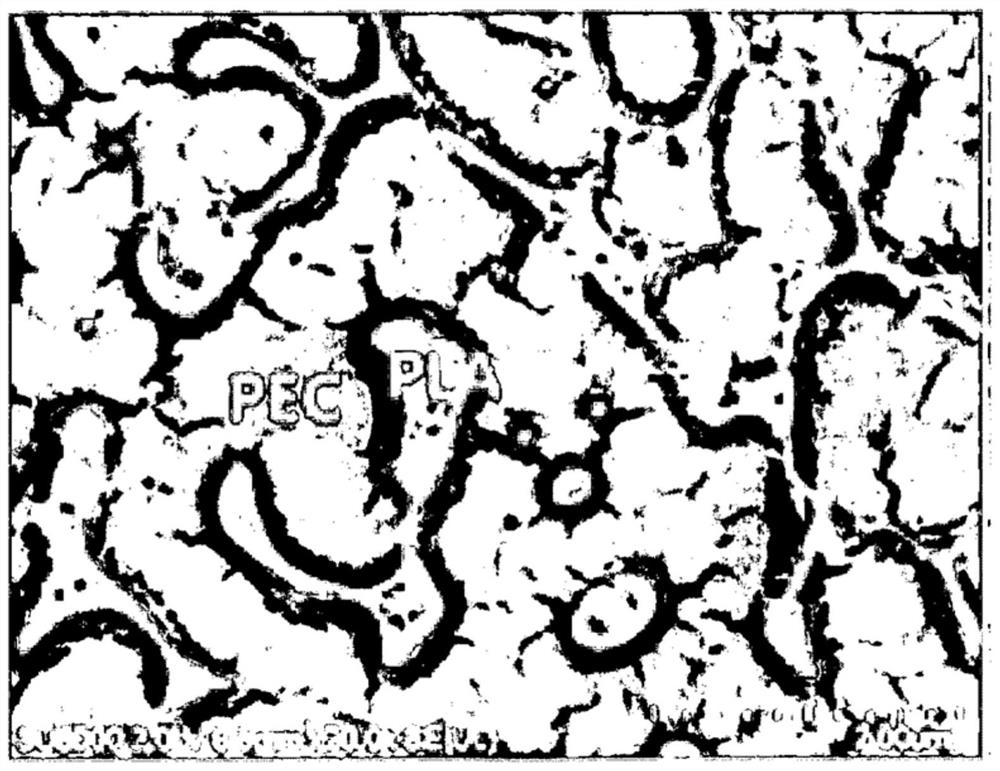

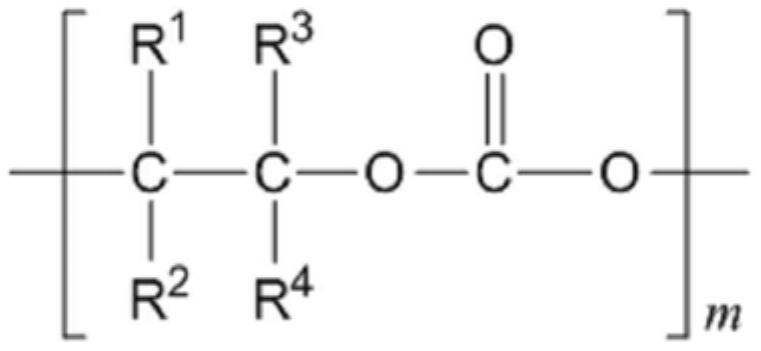

[0092] Preparation Example 1: Preparation of Polyalkylene Carbonate Resin (A1, PEC)

[0093] Polyethylene carbonate resins were prepared by copolymerizing ethylene oxide and carbon dioxide using a diethylzinc catalyst as follows (Journal of Polymer Science B 1969, 7, 287; Journal of Controlled release 1997, 49, 263).

[0094] 1 g of dry diethylzinc catalyst and 10 mL of dioxane solvent were introduced into an autoclave reactor equipped with a stirrer, and then 0.1 g of diluted purified water was added to 5 mL of dioxane solvent while stirring slowly. Subsequently, carbon dioxide was charged into the reactor to a pressure of about 10 atm, and then the solution was stirred at 120° C. for 1 hour. Then, 10 g of purified ethylene oxide was added, carbon dioxide was charged again to a pressure of about 50 atm, and then the temperature was adjusted to 60° C. and the reaction was carried out for about 48 hours. After the reaction, unreacted ethylene oxide was removed under low pres...

preparation Embodiment 2

[0096] Preparation Example 2: Preparation of Polyketone Resin (B1, PK)

[0097] Polyketone (Hyosung, M620A) pellets were used, and the MI of the ketone resin was 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com