High strength thin steel sheet having excellent plating and elongation property and the method for manufacturing the same

A high-strength, thin steel plate technology, applied in the field of deep-drawn thin steel plates, can solve problems such as damage to the properties of plated steel plates, and achieve the effects of excellent plating properties, improved deep drawability, and excellent elongation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0080] The present invention will now be described in more detail with reference to the following examples. These examples are provided only to illustrate the present invention and should not be construed as limiting the scope and spirit of the present invention.

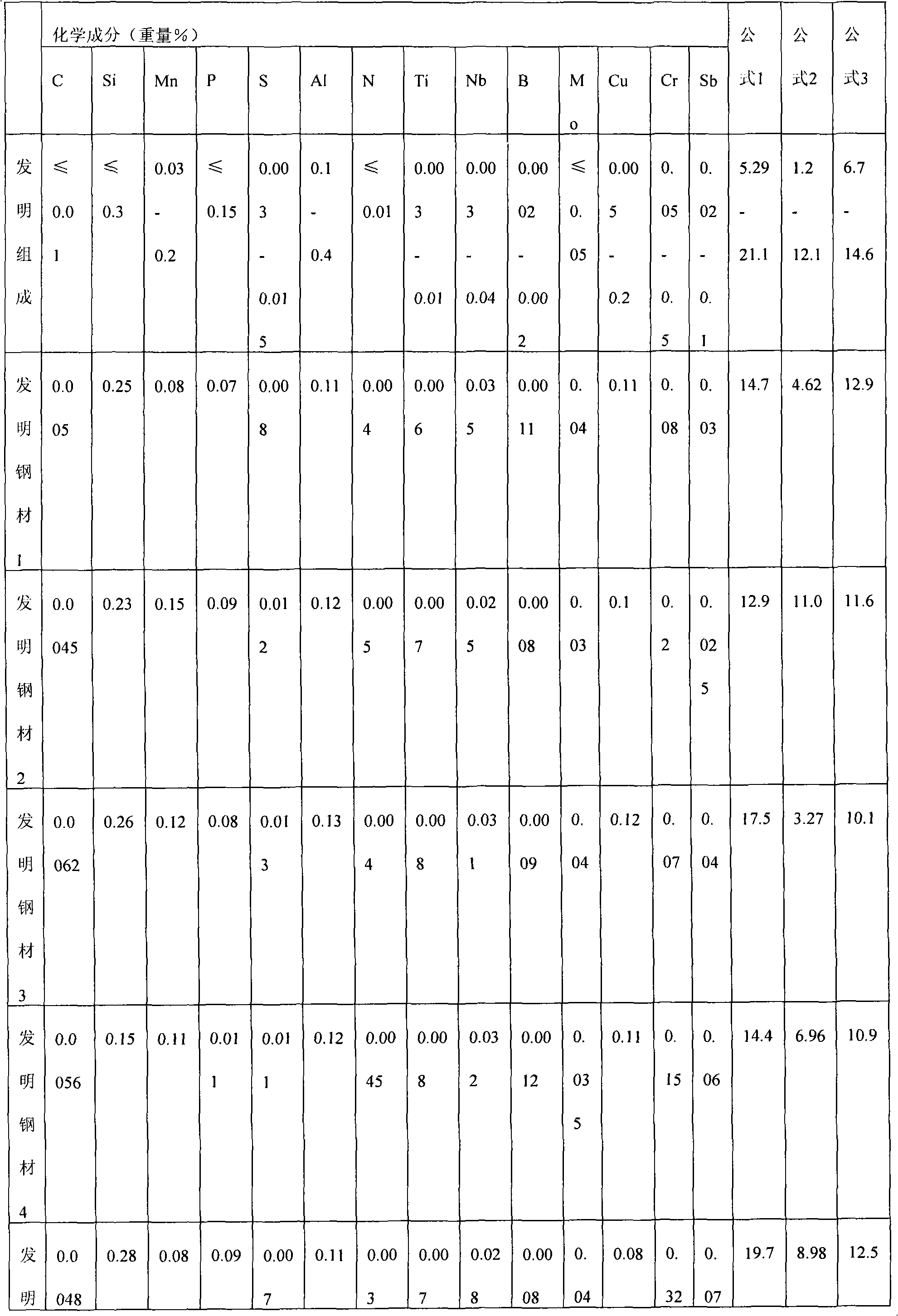

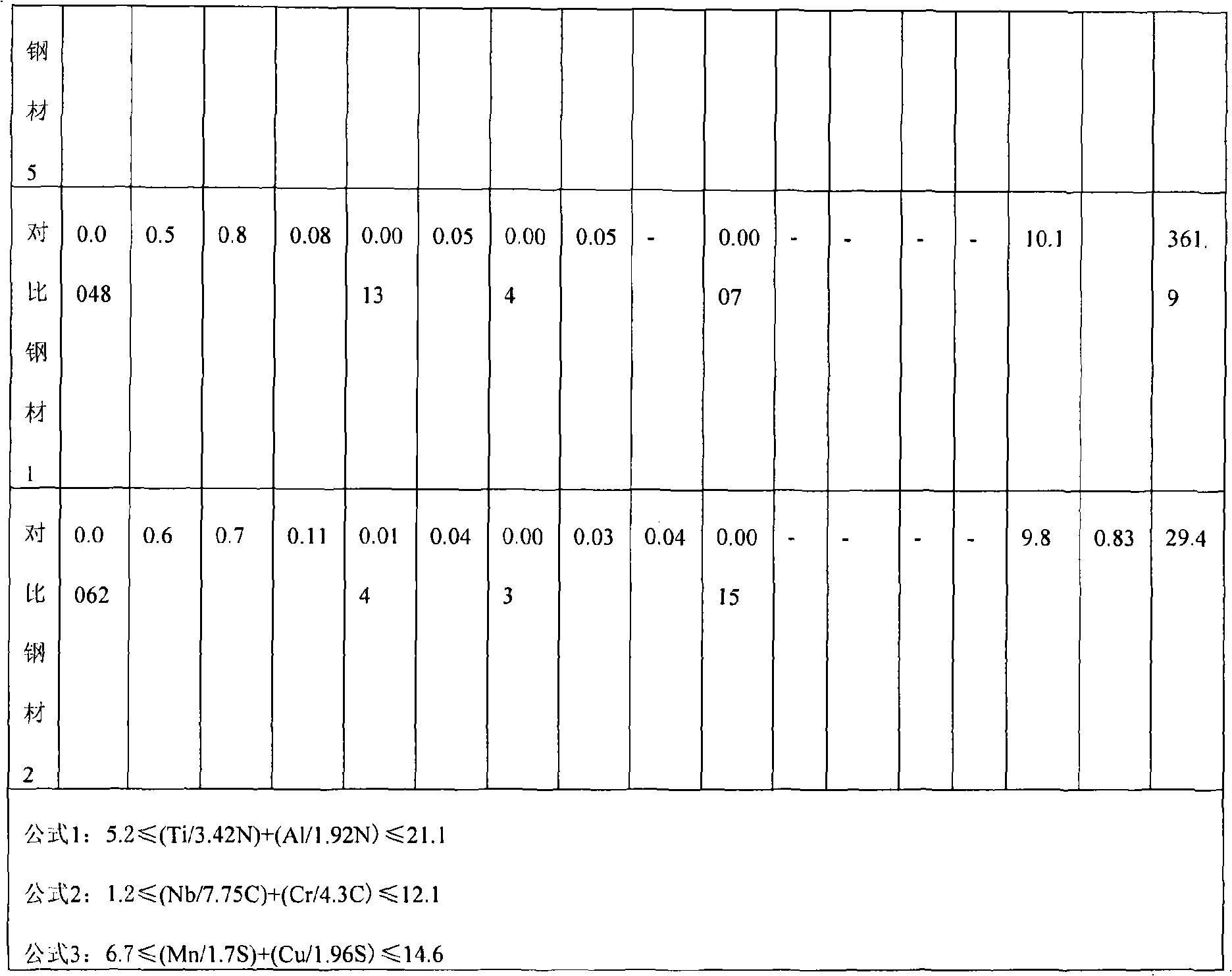

Embodiment

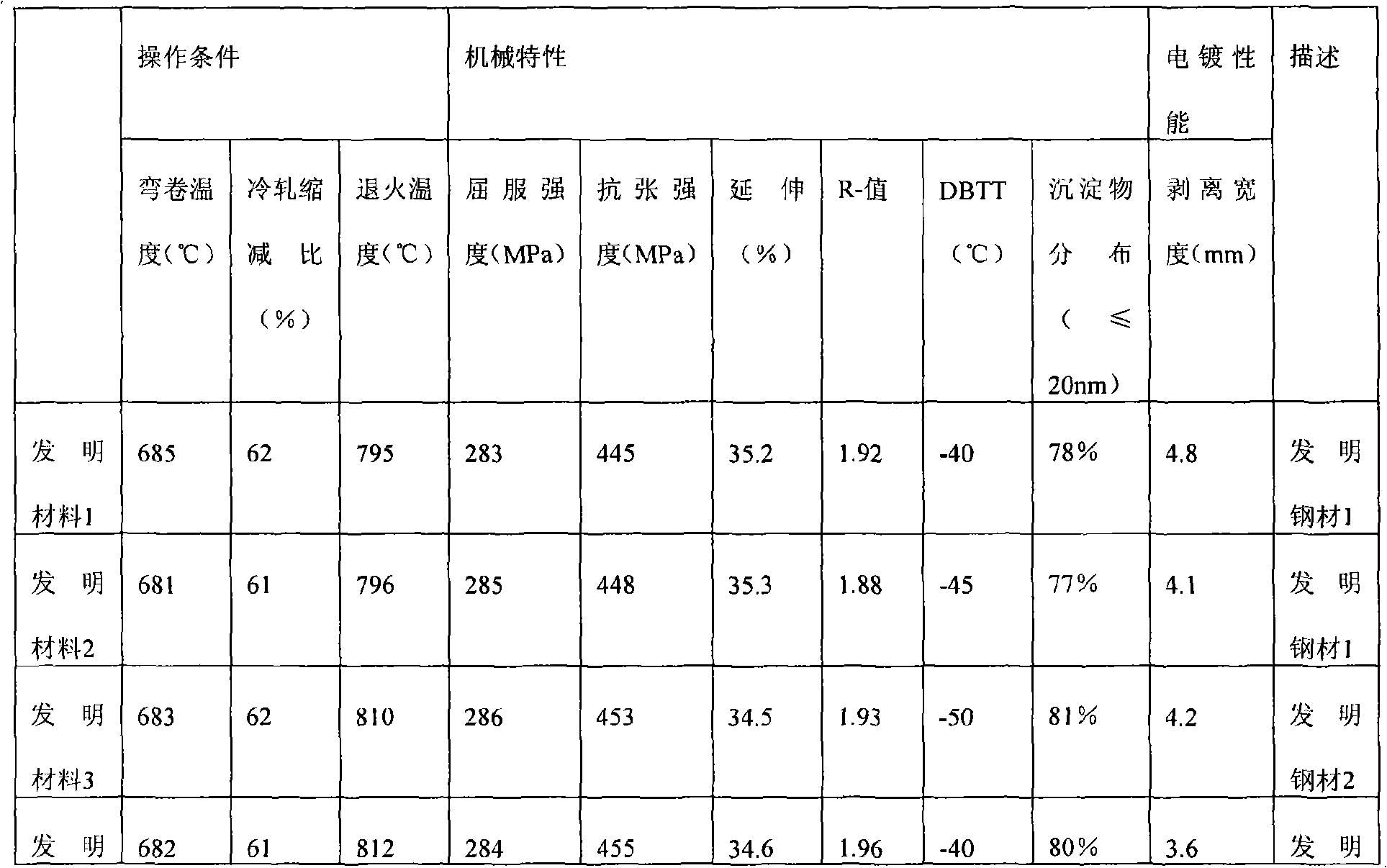

[0082] Thick steel plates having the steel composition shown in Table 1 below were reheated at 1200°C, and at 910°C (higher than Ar 3 Transformation point) hot finish rolling. Then, the hot-rolled steel sheets were bent under the production conditions shown in Table 2 below, and then cold-rolled. At the continuous annealing temperature given in Table 2, the cold-rolled steel sheet was heated to the crack temperature at a rate of 10° C. / second and held at this temperature for 40 seconds.

[0083] For the inspection of mechanical properties, the annealed steel sheets obtained as above were treated as standard test specimens in accordance with the ASTM E-8 standard. The yield strength, tensile strength, elongation (property) and plastic anisotropy coefficient (r m value) and plane anisotropy coefficient (△r value).

[0084] In this paper, r is calculated by the following equation m value and △r value:

[0085] r m =(r 0 +2r 45 + r 90 ) / 4;

[0086] △r=(r 0 +2r 45 ten r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com