Method for improving adhesion between wood and paint film

A paint film adhesion and wood technology, applied in wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of affecting the surface paint film adhesion, shortening the service life of wood, and heavy texture, so as to achieve mechanical properties without damage, Enhanced adhesion and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

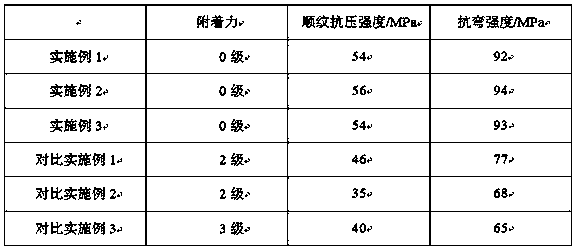

Examples

Embodiment 1

[0016] A method for improving the adhesion between wood and paint film, including the following steps:

[0017] (1) Put the wood into a sealed device, and pass hydrogen into it. When the pressure reaches 0.5MPa, stop the flow, keep the pressure treatment for 20min, then pump to vacuum -0.08MPa, after 30min of vacuum treatment, pass into it Argon gas, until the pressure is 1.2MPa, keep the pressure for 40min, vacuum again to -0.08MPa, keep for 20min, and return to normal pressure;

[0018] (2) Use a modifier to coat the wood obtained in step (1), put it into the sealing device after coating, repeat the operation and treatment steps of step (1) again, and finally return to normal pressure;

[0019] (3) Put the wood obtained in step (2) into a 62°C water bath to soak for 2 hours, then take it out and soak it in an acetic acid solution again, keep it for 35 hours, and then dry it with supercritical carbon dioxide fluid; the concentration of the acetic acid solution is 8%;

[0020] (4) Tre...

Embodiment 2

[0023] A method for improving the adhesion between wood and paint film, including the following steps:

[0024] (1) Put the wood into a sealed device, and pass hydrogen into it. When the pressure reaches 0.7MPa, stop the flow, keep the pressure for 25min, then vacuum to -0.085MPa, after 40min of vacuum treatment, pass into it Argon gas, until the pressure is 1.3MPa, hold the pressure for 50min, vacuum again to -0.085MPa, hold for 25min, and return to normal pressure;

[0025] (2) Use a modifier to coat the wood obtained in step (1), put it into the sealing device after coating, repeat the operation and treatment steps of step (1) again, and finally return to normal pressure;

[0026] (3) Put the wood obtained in step (2) into a 63°C water bath to soak for 3 hours, then take it out and soak it in an acetic acid solution again for 38 hours, and then dry it with supercritical carbon dioxide fluid; the concentration of the acetic acid solution is 9%.

[0027] (4) Treat the wood obtained i...

Embodiment 3

[0030] A method for improving the adhesion between wood and paint film, including the following steps:

[0031] (1) Put the wood into a sealed device, and pass hydrogen gas into it. When the pressure reaches 0.8MPa, stop the gas flow, keep the pressure for 30min, then vacuum to -0.09MPa, and pass it into the vacuum after 50min Argon gas, until the pressure is 1.5MPa, hold the pressure for 60min, vacuum again to -0.09MPa, hold for 30min, and return to normal pressure;

[0032] (2) Use a modifier to coat the wood obtained in step (1), put it into the sealing device after coating, repeat the operation and treatment steps of step (1) again, and finally return to normal pressure;

[0033] (3) Put the wood obtained in step (2) into a 65°C water bath to soak for 3 hours, then take it out and soak it in an acetic acid solution again for 39 hours, and then dry it with supercritical carbon dioxide fluid; the concentration of the acetic acid solution is 10%.

[0034] (4) Treat the wood obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com