Construction method of ecological concrete protected slope based on vertical drainage channel

An ecological concrete and vertical drainage technology, applied in soil protection, infrastructure engineering, botanical equipment and methods, etc., can solve problems such as landscape, environmental and ecological impacts, threats to the ecological environment, deterioration of water bodies and land environments, etc. Achieve the effect of reducing costs, saving manpower and material resources, and reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

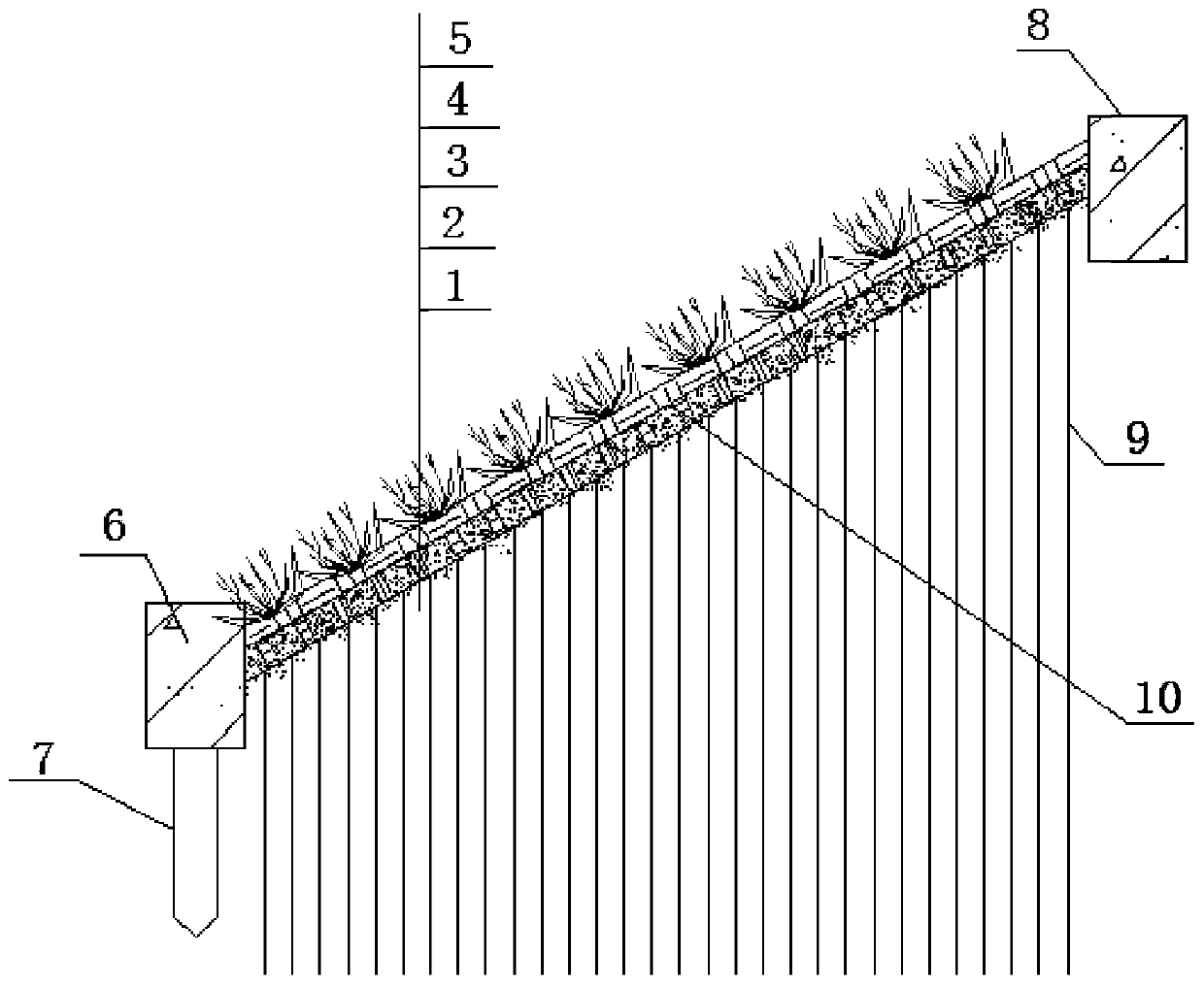

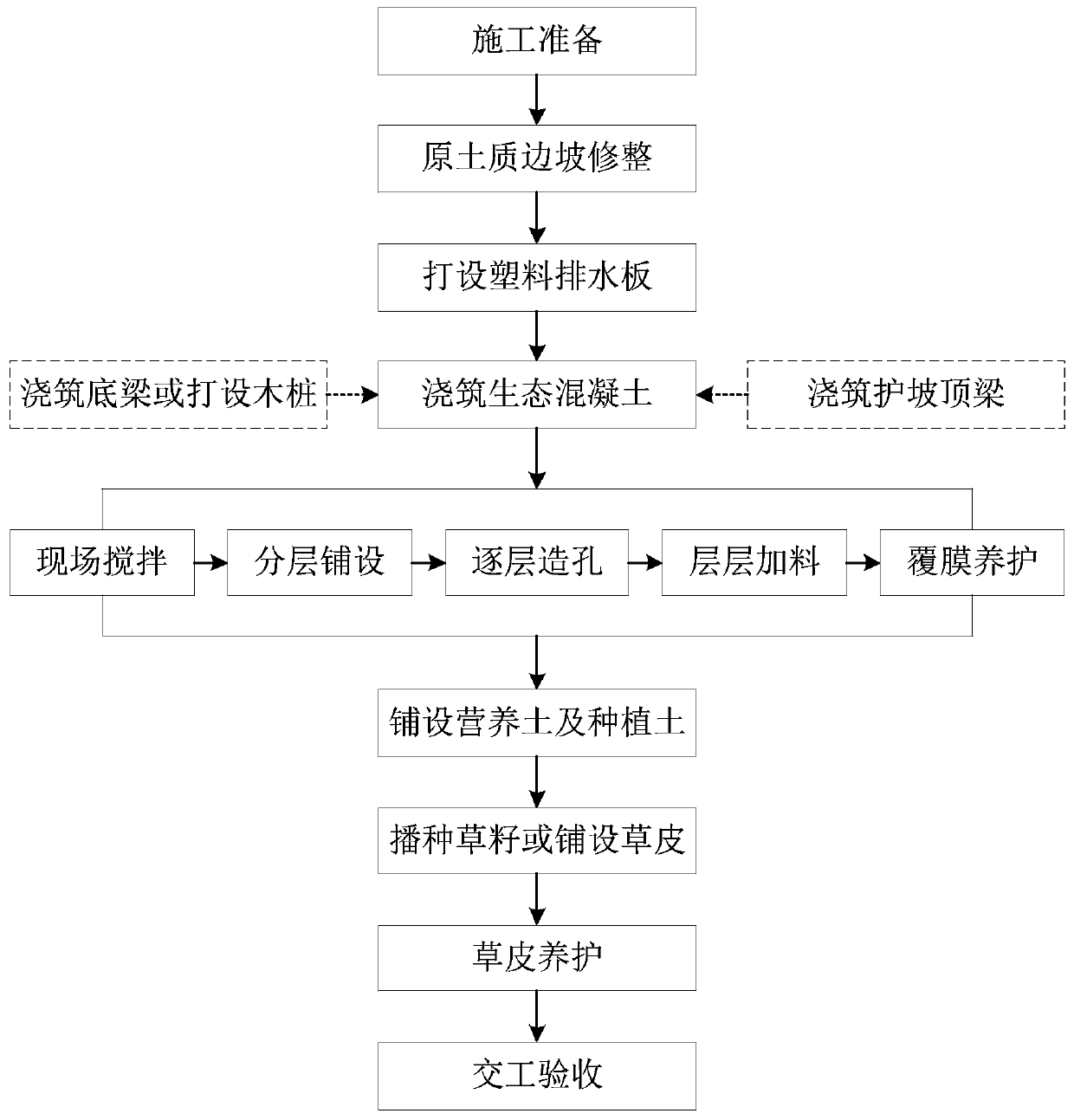

[0032] An ecological concrete slope protection construction method based on a vertical drainage channel, comprising the following steps:

[0033] The first step, undisturbed soil slope 1 trimming and slope cutting

[0034] The sundries on the surface of the original soil slope 1 are removed, and the original soil slope 1 is trimmed, slope cut, and compacted according to the slope ratio and structural requirements for forming slope protection.

[0035] The second step is to set up the plastic drainage board 9

[0036] Before laying the plastic drainage board 9, use GPS to measure and release the construction sidelines of each area, arrange the points of the plastic drainage board in a square or plum blossom shape, and the distance between adjacent plastic drainage board points is 1m, and use the plugging machine to punch the plastic drainage board 9 Set to design depth, the board head of plastic drainage board 9 exposes 30cm on the ground.

[0037] The third step, pouring eco...

Embodiment 2

[0048] The difference between this embodiment and Example 1 is that the matrix balls are filled into the holes 10 of each layer of ecological greening concrete, and the matrix balls are spheroids made of soil, slow-release fertilizer, organic matter, and water-retaining materials. 5mm to 10mm. The matrix ball is composed of the following components in mass percentage: 90% soil, 4% slow-release fertilizer, 3% organic matter, and 3% water-retaining material. The preparation process of the matrix ball is as follows: mix the soil, slow-release fertilizer, organic matter, and water-retaining materials according to the above ratio and stir evenly, then add an appropriate amount of water, mechanically make the stirred mixture into a spherical shape, and then screen out the design after drying. particle size matrix balls. Among them, the soil is ordinary planting soil, the slow-release fertilizer is magnesium ammonium phosphate, the organic matter is flour (the flour can be wheat flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com