Pile body quality monitoring method and monitoring device thereof

A quality monitoring and measuring device technology, applied to measuring devices, measuring electrical variables, measuring current/voltage, etc., can solve the problems of stopping in holes, recording, and inability to query records, etc., and achieve the effect of preventing loss and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the specific embodiments described here are only used to illustrate and explain the present invention, not to limit the present invention.

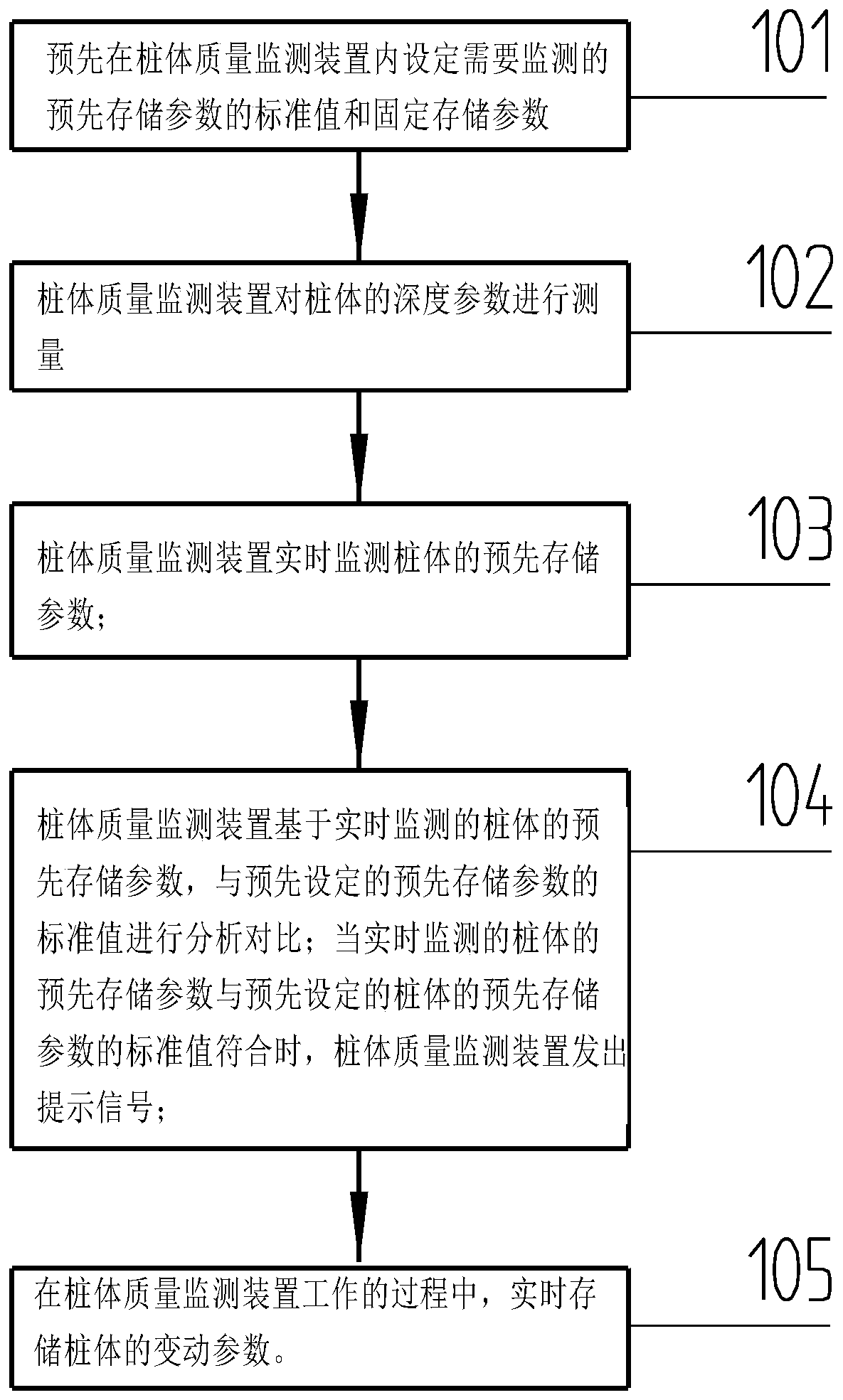

[0048] The invention provides a method for monitoring pile body quality, referring to figure 1 , figure 1 Shown is a kind of flow chart of the embodiment 1 of pile body quality monitoring method; figure 1 As shown, the method includes the following steps:

[0049] In step 101, the standard values and fixed storage parameters of the pre-stored parameters to be monitored are set in advance in the pile quality monitoring device; the standard values of the pre-stored parameters involved in this step include encryption current parameter standard values, vibration retention The standard value of the time parameter, the encrypted current parameter is also called the dense current par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com