Iron-based amorphous soft magnetic alloy and preparation method thereof

An iron-based amorphous and soft magnetic alloy technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of reduced amorphous forming ability, low cost, and reduced maximum saturation magnetic induction intensity, achieving strong forming ability, The effect of excellent toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

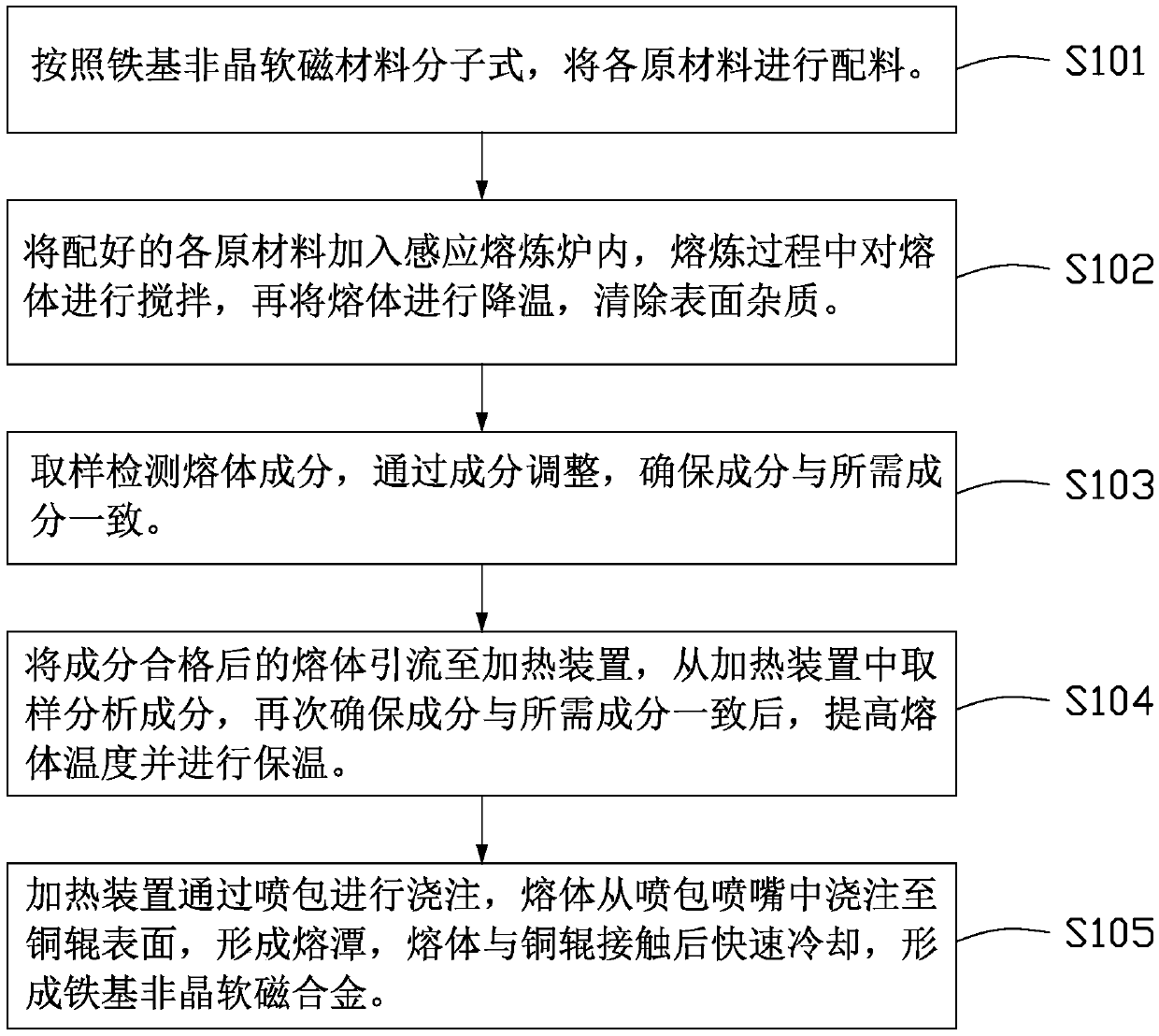

[0028] In order to make the technical solutions, objectives and advantages of the solutions of the present invention clearer, the technology of the present invention will be further described in detail through implementation cases. It should be known that the detailed implementation cases here are only used for explaining the present invention, and do not limit the present invention.

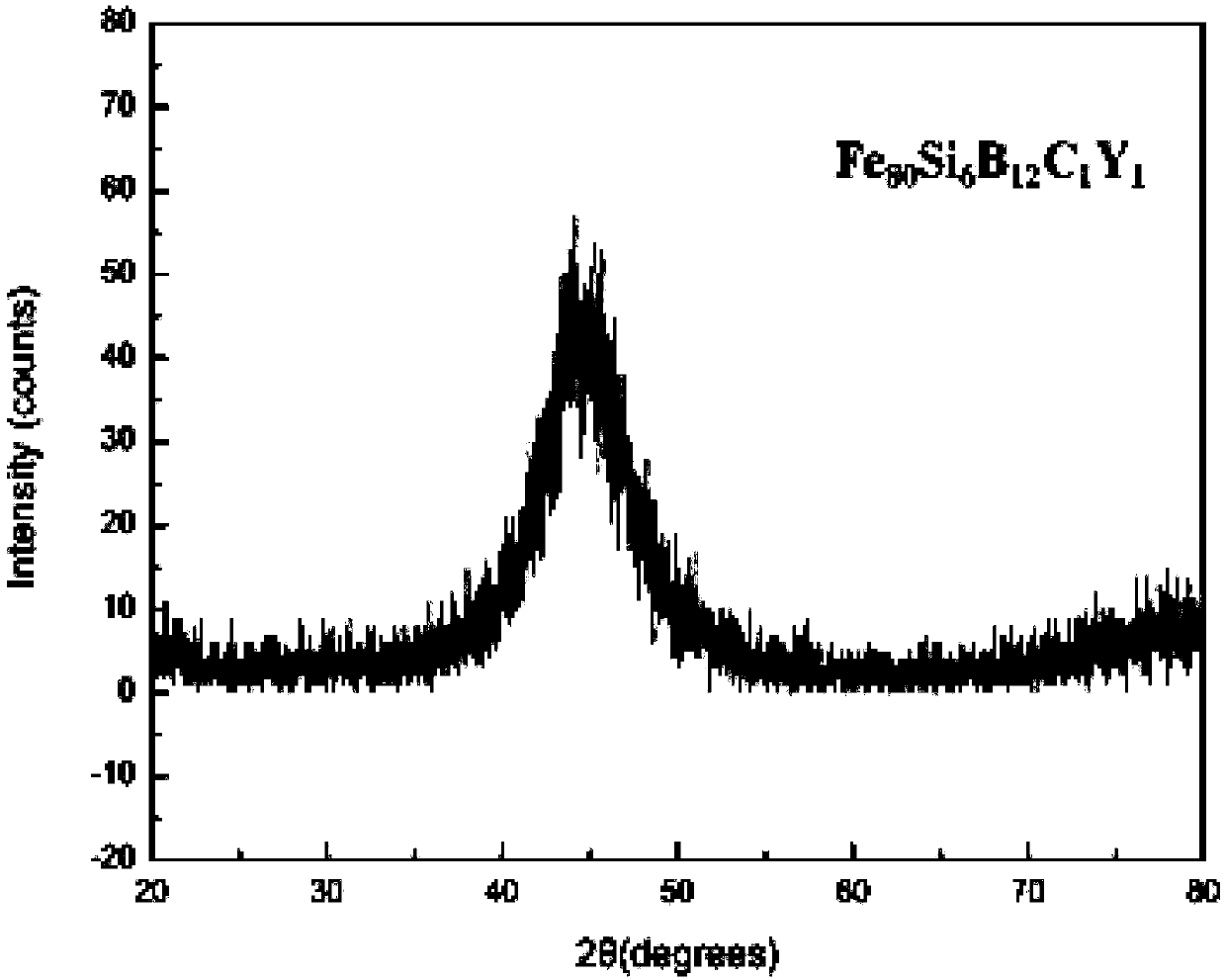

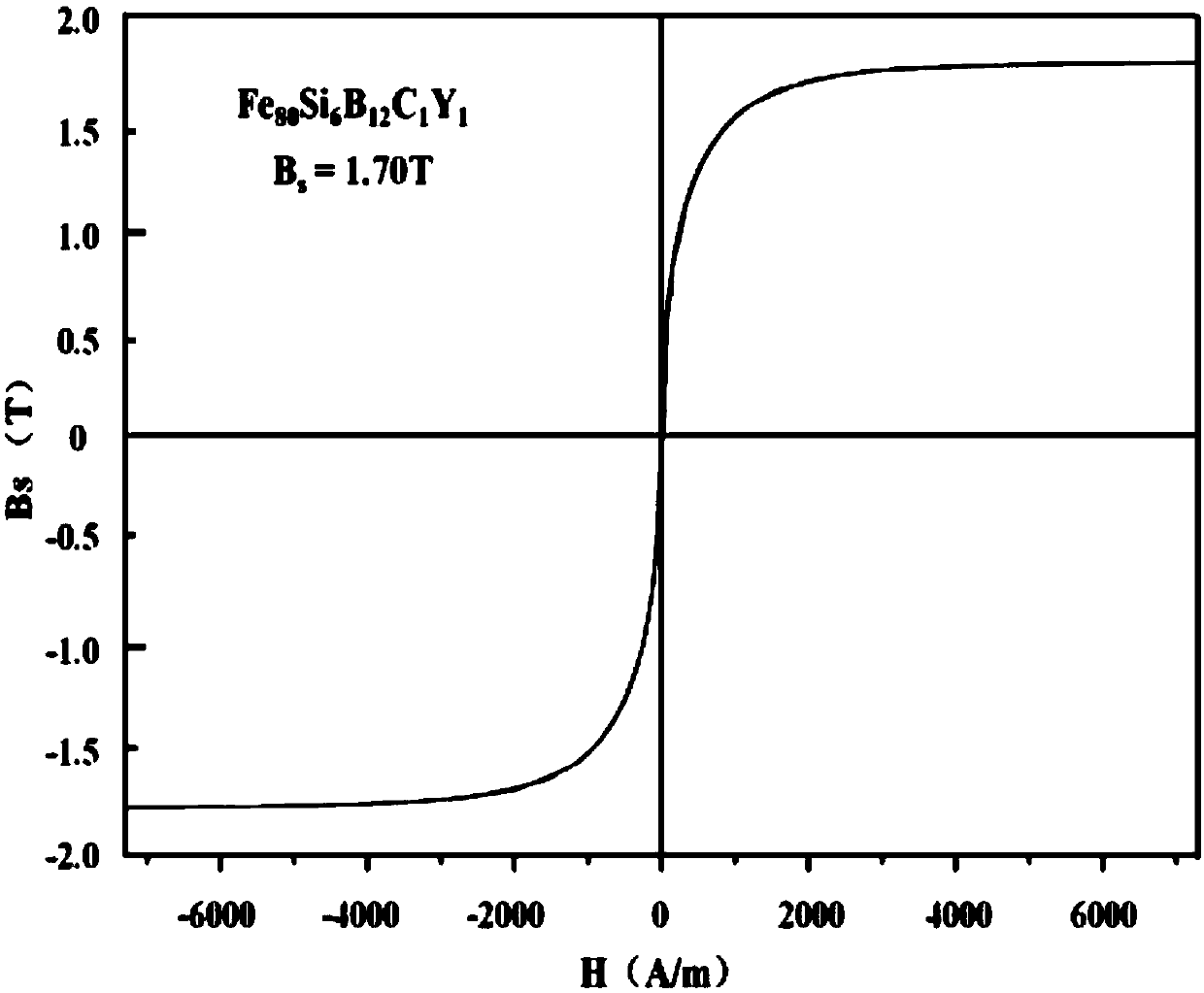

[0029] The invention provides an iron-based amorphous soft magnetic material, on the basis of the common iron-silicon-boron ternary composition, by adding carbon element, its saturation magnetic induction intensity can be effectively improved; by adding yttrium element, it can purify molten steel , remove oxidation and improve the quality of molten steel; and with the addition of small atomic size carbon and large atomic size yttrium, the difference in the size of each group of atoms in the system increases, which can improve the amorphous forming ability of the system. The molecular formula of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com