Terbium ion activated scintillation glass for producing scintillation optical fiber panels and preparation method thereof

A technology of scintillation glass and scintillation optical fiber, which is applied in the field of terbium ion activated scintillation glass and its preparation, can solve the problems of inability to realize high-resolution spatial imaging of observation targets, unimproved thermal processing performance, and inapplicability of scintillation optical fiber panels, etc., to achieve Good transparency and radiation resistance, excellent crystallization resistance, and easy chemical composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

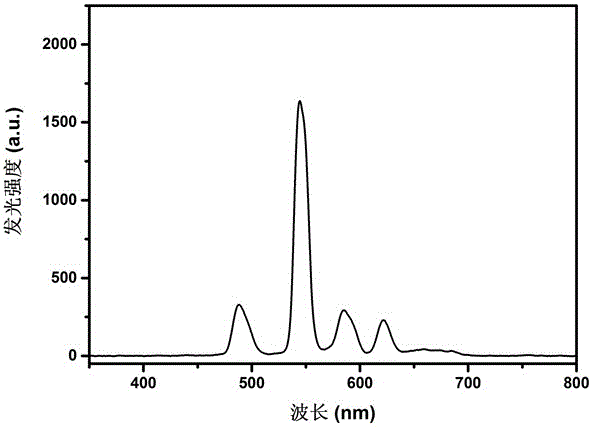

[0022] According to the chemical composition of the glass in Example 1 in Table 1, the raw materials were weighed, mixed and ground in a mortar to obtain the complex; the complex was poured into a platinum crucible and melted into a melt in a glass melting furnace, and the melting temperature was 1400~ 1500°C, keep warm for 2 to 4 hours after melting, stir the glass melt every 0.5 hours during the heat preservation period, and stir for 0.5 hours to improve the melting quality and clarification quality of the glass melt; pour the melted glass melt Put the glass into a cast iron mold preheated at 400-500°C. After cooling and forming, place the glass in a muffle furnace at 600-700°C for annealing. After the holding time is 4 hours, turn off the power of the muffle furnace, and then cool down to room temperature with the furnace; The annealed scintillation glass is processed into terbium ion-activated scintillation glass for preparing scintillation optical fiber panels after cuttin...

Embodiment 2

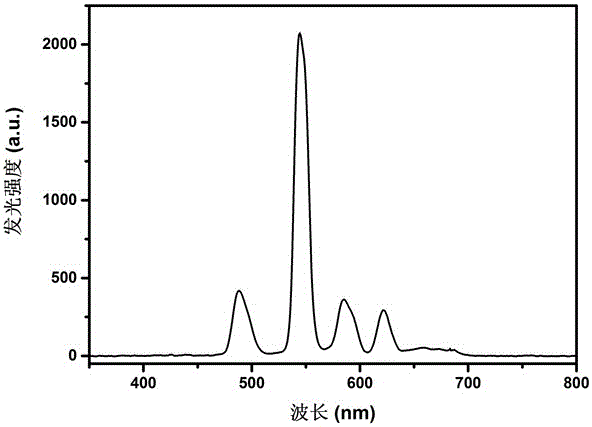

[0024] The raw materials were weighed according to the glass component of Example 2 in Table 1, and the same melting process system and test conditions as in Example 1 were adopted. The performance of the obtained scintillation glass is: density 4.168g / cm 3 ; Refractive index 1.637; 30 ~ 300 ℃ average linear expansion coefficient 85 × 10 -7 / °C; the expansion softening point temperature is 756°C; the scintillation glass sample is excited by X-rays, and the emitted fluorescence is measured to obtain figure 2 In the emission spectrum diagram shown, the wavelength range is 450-700nm, and the strongest luminescence peak is located at 545nm.

Embodiment 3

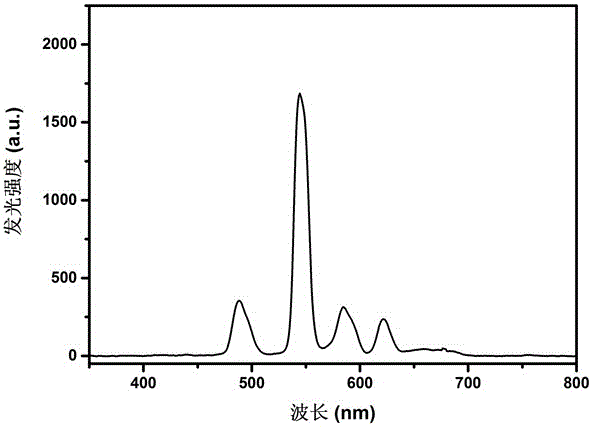

[0026] The raw materials were weighed according to the glass component of Example 3 in Table 1, and the same melting process system and test conditions as in Example 1 were adopted. The performance of the obtained scintillation glass is: density 4.278g / cm 3 ; Refractive index 1.655; 30 ~ 300 ℃ average linear expansion coefficient 86 × 10 -7 / °C; the expansion softening point temperature is 789°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Average linear expansion coefficient | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com