Manganese-based amorphous alloy and preparation method and application thereof

An amorphous alloy, manganese-based technology, applied in the field of manganese-based amorphous alloy and its preparation, to achieve the effect of promoting large-scale application, excellent thermal stability, and excellent amorphous forming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

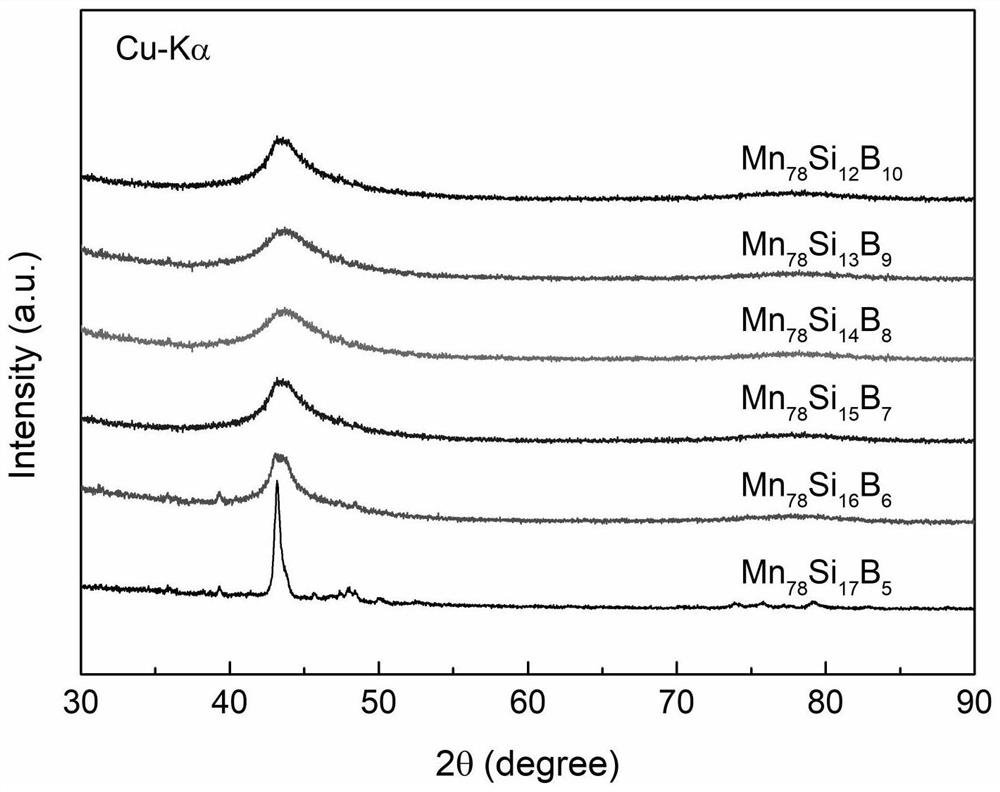

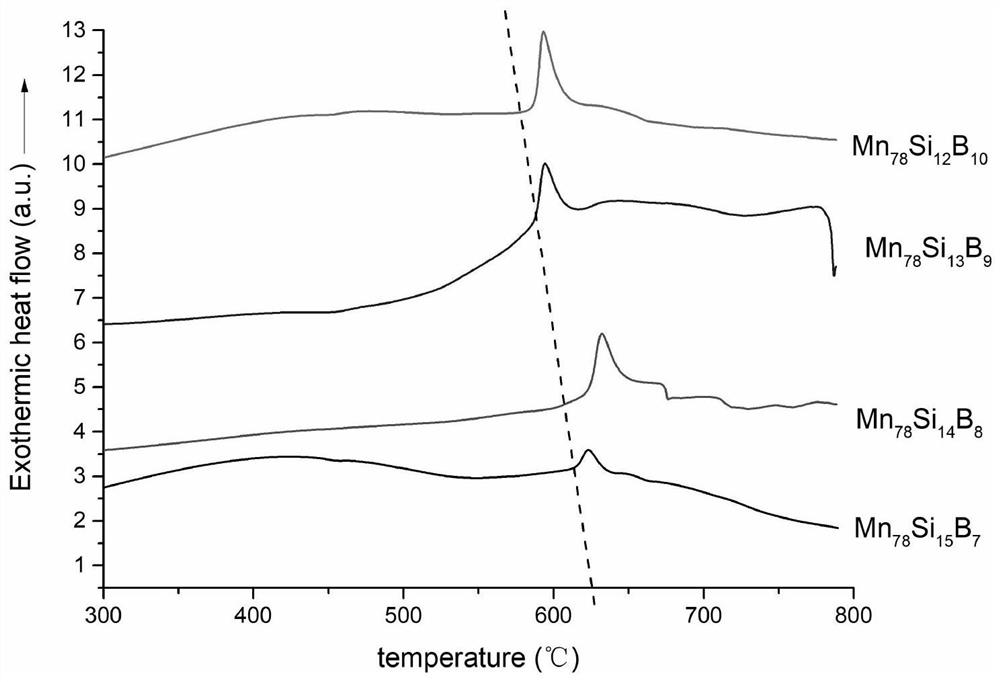

[0032] Manganese-based amorphous alloys are prepared according to the chemical expression shown in Table 1, and the preparation method is as follows:

[0033] (1) carry out batching according to each element atomic percentage proportioning of alloy composition, the required amount of elemental element B, Mn, Si in the batching process is Mn-B (the content of B is 3.35wt%) and Mn-Si (the content of Si is 3.35wt%) The content is 3.35wt%) to add as master alloy, supplemented with trace amounts of Mn, Si, B elemental substances as required;

[0034] (2) Use WK-IIA type non-consumable vacuum arc melting furnace for melting. In order to ensure the quality of the master alloy, the furnace body is evacuated before smelting to make the vacuum degree reach 3.0×10 -4 Pa, and then into high-purity argon (purity 99.99%). During smelting, reserve a smelting pot to hold titanium ingots, and smelt titanium ingots first to absorb the residual oxygen in the smelting furnace, and then use elec...

Embodiment 2

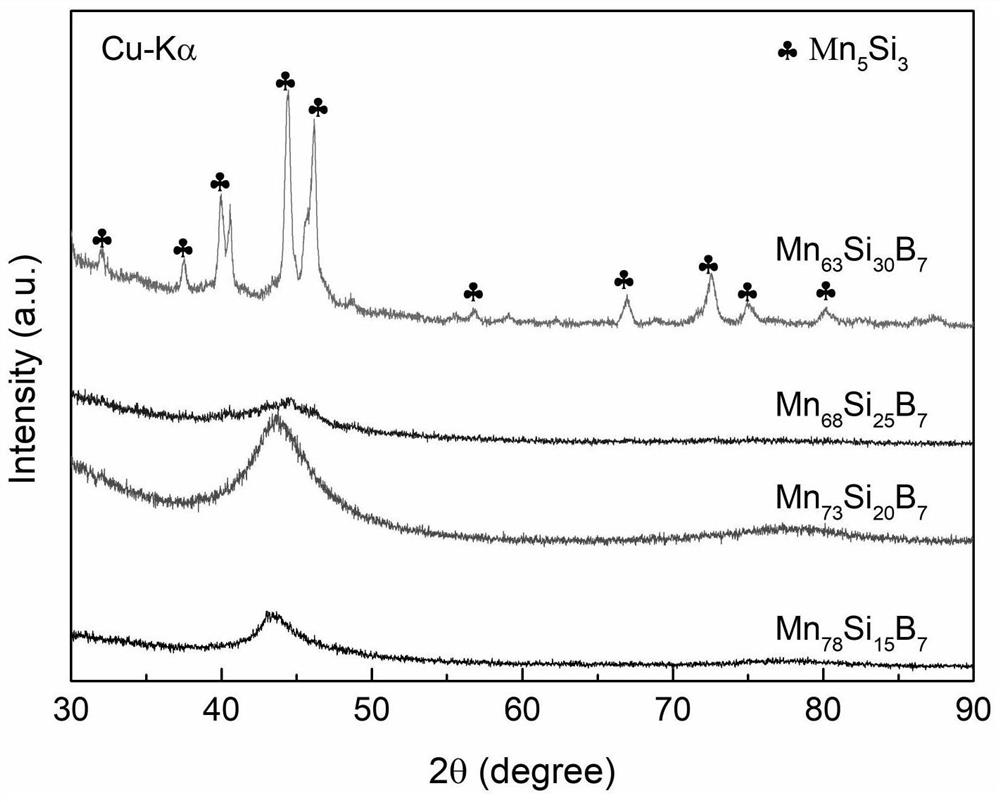

[0043] Manganese-based amorphous alloys are prepared according to the chemical expression shown in Table 2, and the preparation method is as follows:

[0044] (1) carry out batching according to each element atomic percentage proportioning of alloy composition, the required amount of elemental element B, Mn, Si in the batching process is Mn-B (the content of B is 3.35wt%) and Mn-Si (the content of Si is 3.35wt%) The content is 3.35wt%) to add as master alloy, supplemented with trace amounts of Mn, Si, B elemental substances as required;

[0045] (2) Use WK-IIA type non-consumable vacuum arc melting furnace for melting. In order to ensure the quality of the master alloy, the furnace body is evacuated before smelting to make the vacuum degree reach 3.0×10 -4 Pa, and then into high-purity argon (purity 99.99%). During smelting, reserve a smelting pot to hold titanium ingots, and smelt titanium ingots first to absorb the residual oxygen in the smelting furnace, and then use elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com