Synthesis and application of a high-capacity and stable few-layer molybdenum selenide-collagen-derived carbon composite potassium-ion battery anode material

A collagen and battery negative electrode technology, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve problems such as capacity fading, improve potassium storage performance, volume buffer conductivity, and promote The effect of improving reaction kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Weigh a certain quality of discarded cowhide (referring to the discarded cowhide with hair), ultrasonically pre-treat it, then cut it into pieces with scissors, add 0.5% of the raw material mass to dissolve it, then salt out, and finally freeze-dry and grind it. Crushed to get collagen powder;

[0026] 2) Weigh 1 g of collagen powder and 3 g of molybdenum acetylacetonate into 0.2 L of deionized water, stir rapidly for 12 h, centrifuge and dry in an oven at 70 °C;

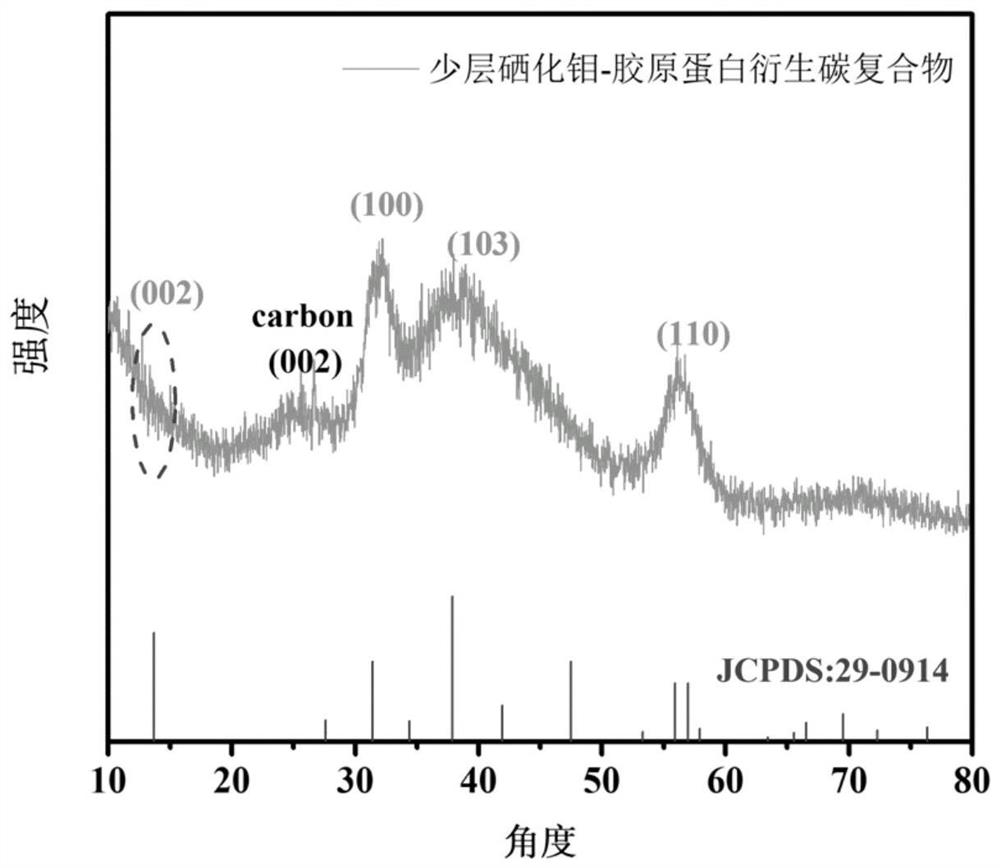

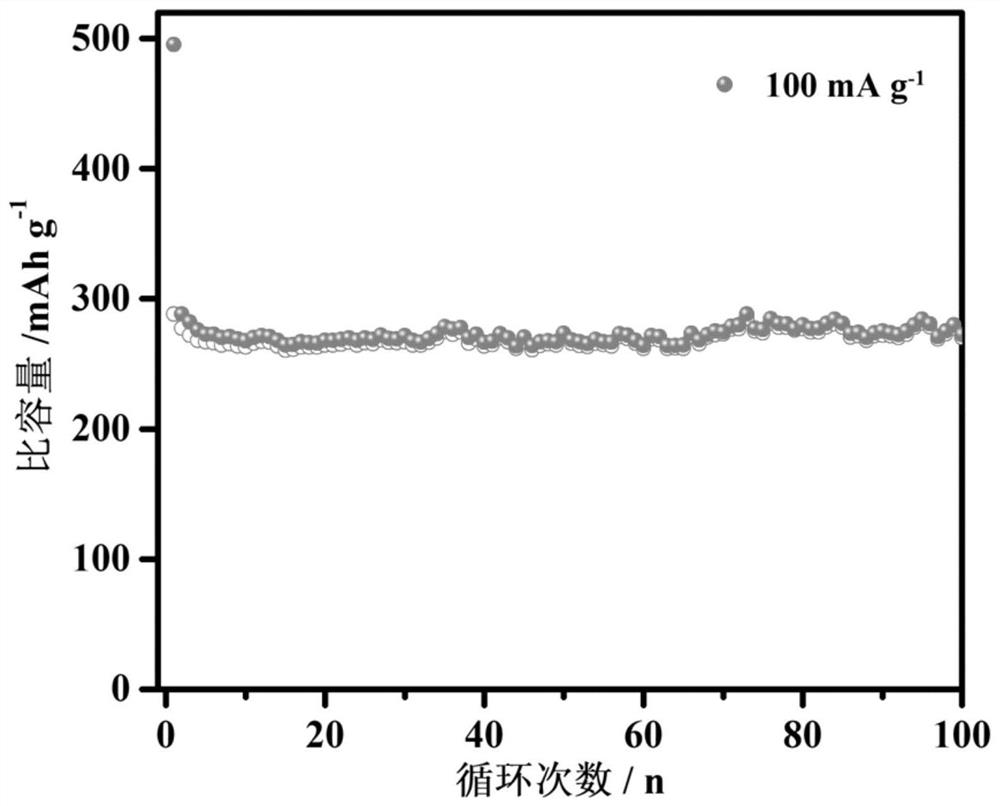

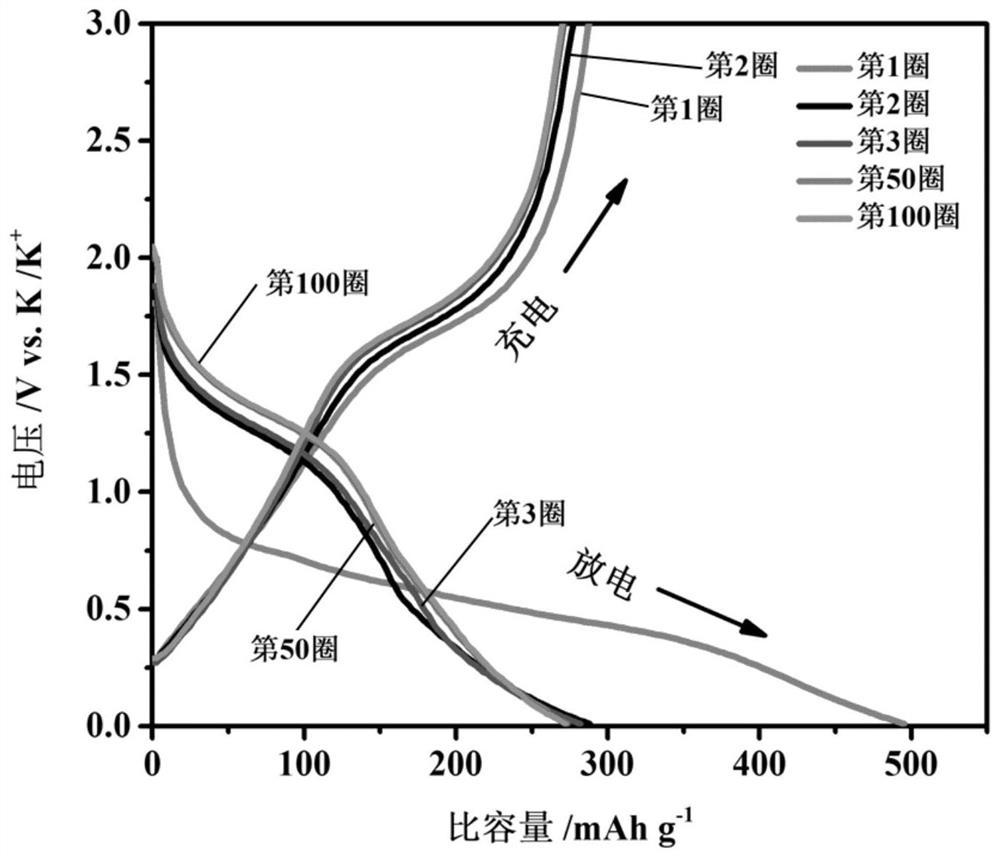

[0027] 3) Grind the bulk solid obtained in step 2) into powder, then weigh the solid powder and selenium powder with a mass ratio of 1:3 and place them in two corundum boats respectively, and place them in a volume ratio of 95%Ar / 5%H. 2 After calcination at 700 °C for 4 hours in an atmosphere tube furnace, a black solid sample was collected, which is a high-capacity and stable few-layer molybdenum selenide-collagen-derived carbon composite potassium ion battery anode material—few-layer molybdenum selenide- ...

Embodiment 2

[0030] 1) Weigh a certain quality of discarded cowhide (referring to the discarded cowhide with hair), ultrasonically pre-treat it, then cut it into pieces with scissors, add papain accounting for 0.7% of the raw material mass to dissolve, then salt out, and finally freeze-dry and grind. Crushed to get collagen powder.

[0031] 2) Weigh 1 g of collagen powder and 4 g of sodium molybdate respectively, add them to 0.3 L of deionized water, stir rapidly for 10 h and centrifuge, and then place them in an oven at 80 °C for drying;

[0032] 3) Grind the bulk solid obtained in step 2) into powder, then weigh the solid powder and selenium powder with a mass ratio of 1:2 and place them in two corundum boats, respectively, and place them in 95%Ar / 5%H 2 calcined at 600 °C for 5 hours in an atmosphere tube furnace, and a black solid sample was collected, which was a few-layer molybdenum selenide-collagen-derived carbon composite;

[0033] The few-layer molybdenum selenide-collagen-derive...

Embodiment 3

[0035] 1) Weigh a certain quality of discarded cowhide (referring to the discarded cowhide with hair), ultrasonically pre-treat it, then cut it into pieces with scissors, add trypsin that accounts for 1% of the raw material mass to dissolve, then salt out, and finally freeze-dry and grind it. Crushed to get collagen powder.

[0036] 2) Weigh 1 g of collagen powder and 5 g of molybdenum acetylacetonate respectively, add them to 0.4 L of deionized water, quickly stir for 24 h and centrifuge, and then place them in an oven at 90 °C for drying;

[0037] 3) Grind the bulk solid obtained in step 2) into powder, then weigh the solid powder and selenium powder with a mass ratio of 1:3 and place them in two corundum boats, respectively, and place them in 95%Ar / 5%H 2 calcined at 800 °C for 4 hours in an atmosphere tube furnace, and collected a black solid sample, which is a few-layer molybdenum selenide-collagen-derived carbon composite;

[0038] The few-layer molybdenum selenide-colla...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap