Aquatic product rapid ice-free freezing structure and method

A fast technology for aquatic products, applied in the direction of freezing/cooling preservation of meat/fish, food preservation, dry preservation of meat/fish, etc. It can solve problems such as deterioration, juice loss, and quality decline, so as to achieve good fresh-keeping effect and ensure nutrition value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

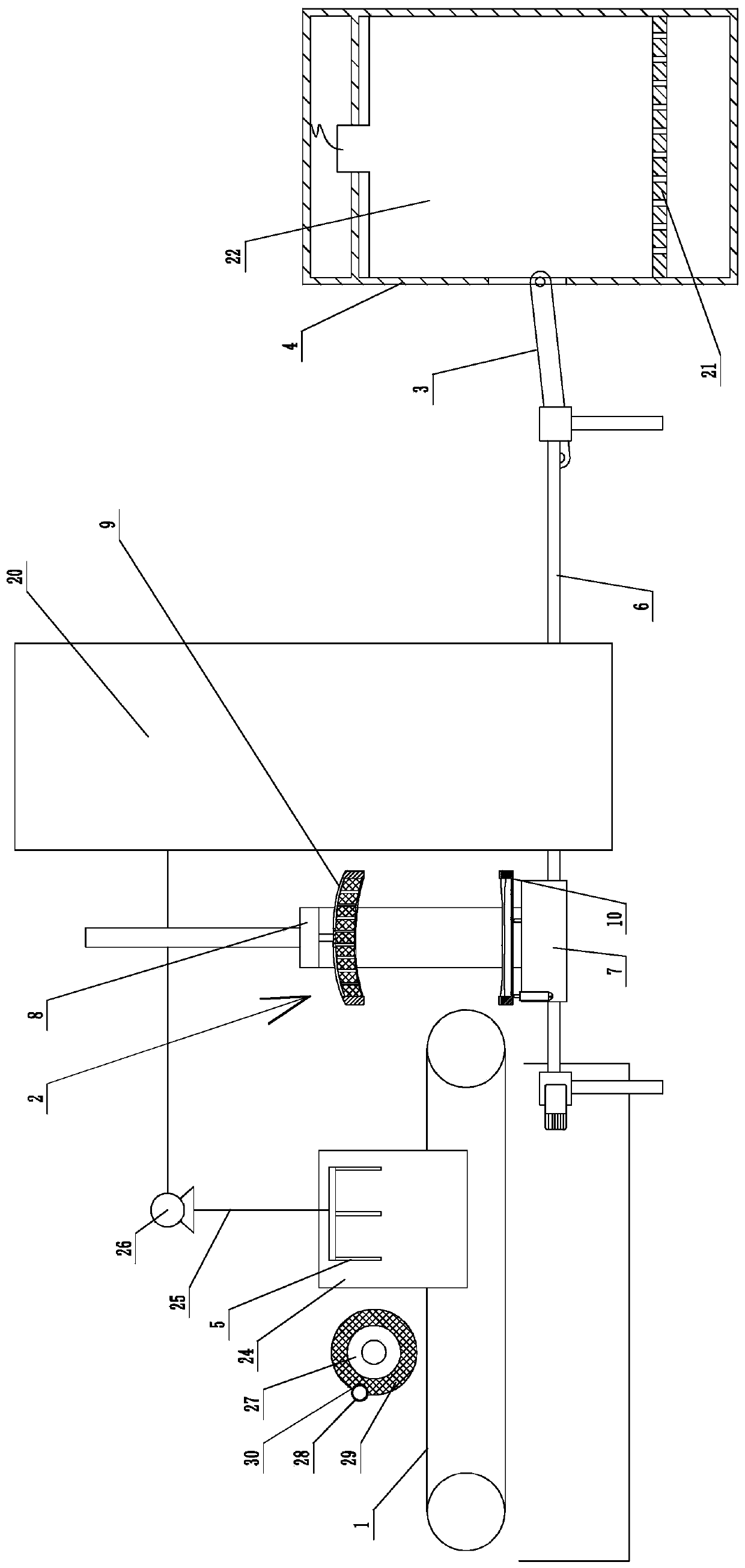

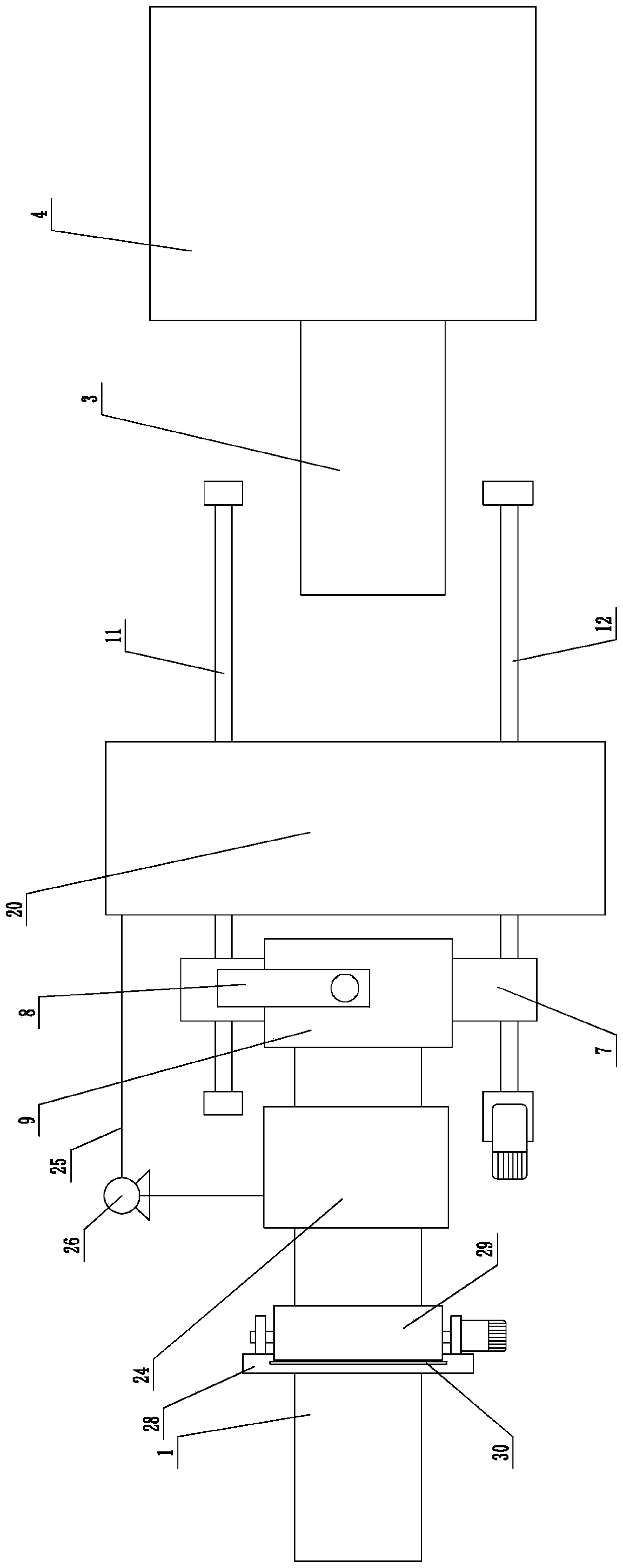

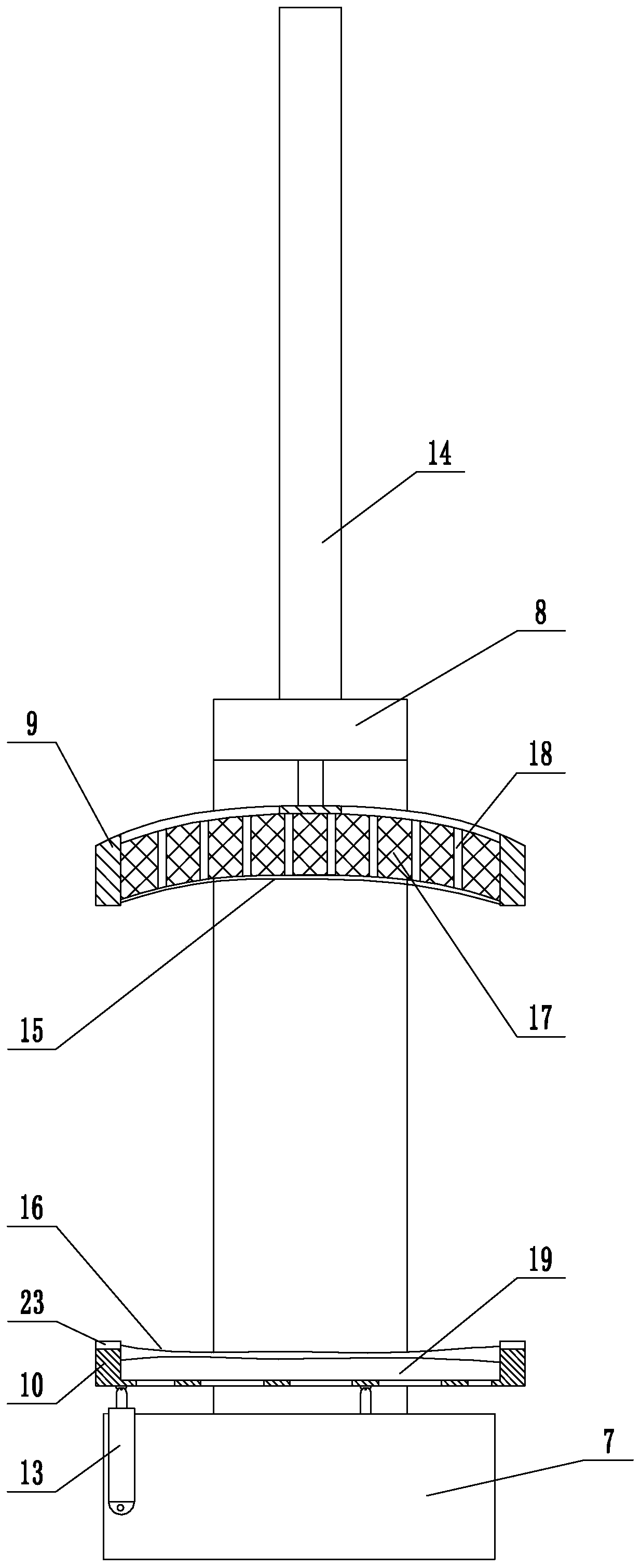

[0021] Embodiment: A kind of aquatic product rapid freezing structure without freezing (see attached figure 1 to attach Figure 5 ), including the feeding conveyor belt 1, the laminating mechanism 2, the feeding conveyor belt 3, and the refrigerator 4. The two ends of the feeding conveyor belt and the feeding conveyor belt are equipped with pulleys, and the pulleys are driven by the motor to rotate, so as to realize Movement of infeed and outfeed conveyor belts. A number of cold air outlet pipes 5 are installed above the feeding conveyor belt, the cold air outlet pipes are arranged towards the feeding conveyor belt, a bracket 6 is installed between the feeding conveyor belt and the unloading conveyor belt, and the laminating mechanism includes a connecting seat 7 and a mounting frame 8 , upper cover 9, lower cover 10, the mounting bracket is arranged on the connecting seat, the guide rod 11 and the threaded driving rod 12 are installed on the bracket, the connecting seat is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com