Single point incremental forming hot air heating working table and using method thereof

A hot air heating, single-point progressive technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of the influence of the surface quality of the sheet, reduce the stiffness of the spindle, and be expensive, so as to reduce the number of supporting equipment, The effect of improving forming accuracy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

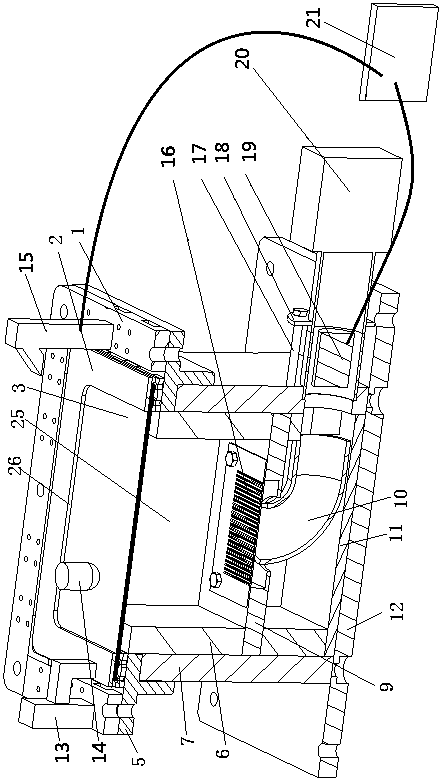

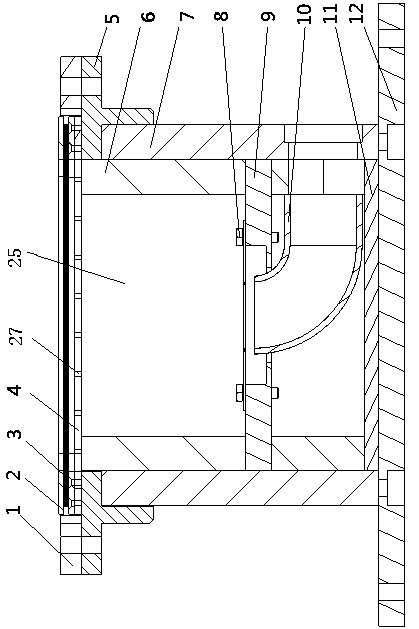

[0032] refer to Figure 1 to Figure 3

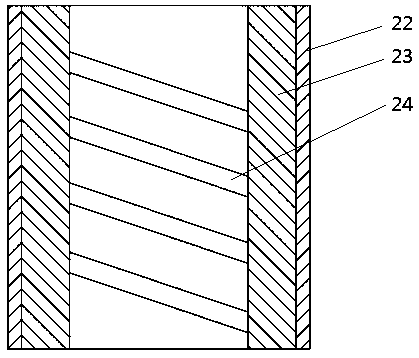

[0033] A single-point incremental forming hot air heating workbench, comprising a base plate 12, on which a support tube 7 is arranged, and an outwardly extending support plate 5 is arranged on the upper end of the support tube. The support plate is provided with a fixed plate 1 with an installation opening, and the side air outlet frame plate 4 installed on the support plate and used to support the blank is arranged in the installation opening. The upper side of the side air outlet frame plate It is provided with a pressing mechanism that cooperates with it to press the billet. A heating chamber 25 is provided in the support tube, and a ventilation pipe 10 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com