3D-printing concrete molding equipment capable of realizing aggregate piling and slurry flowing and molding method

A technology of 3D printing and molding equipment, applied in the field of 3D printing, can solve the problems of 3D printing construction quality, high cement consumption, large volume shrinkage, etc., and achieve the effects of novel design, low production cost, and simple molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

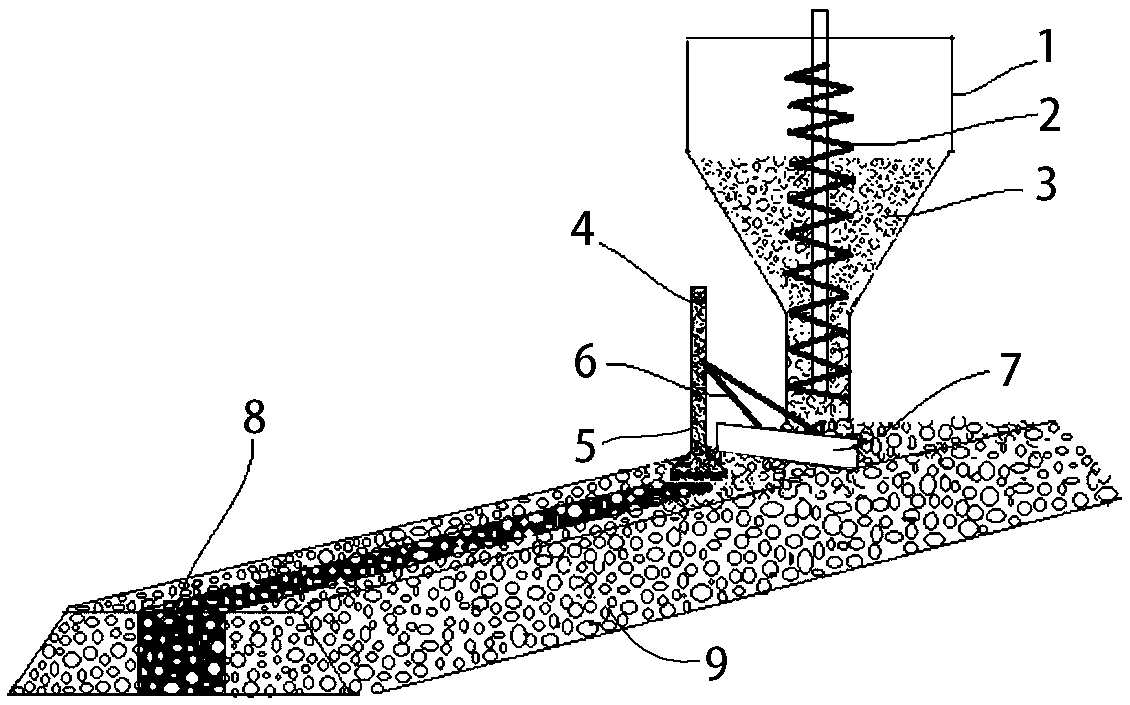

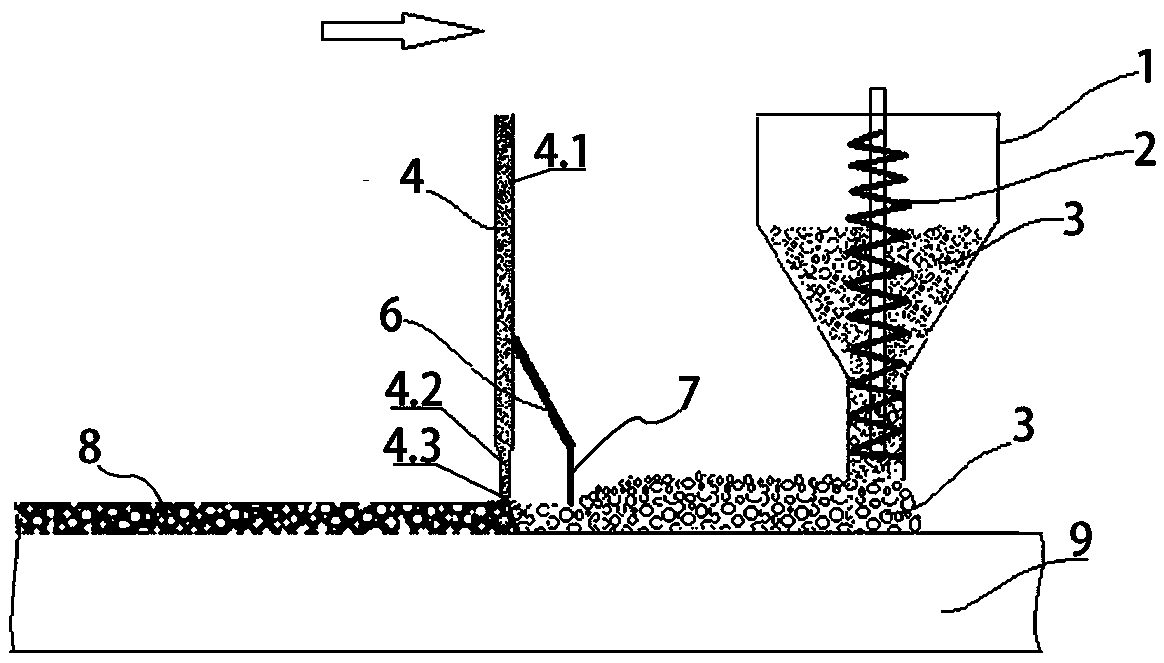

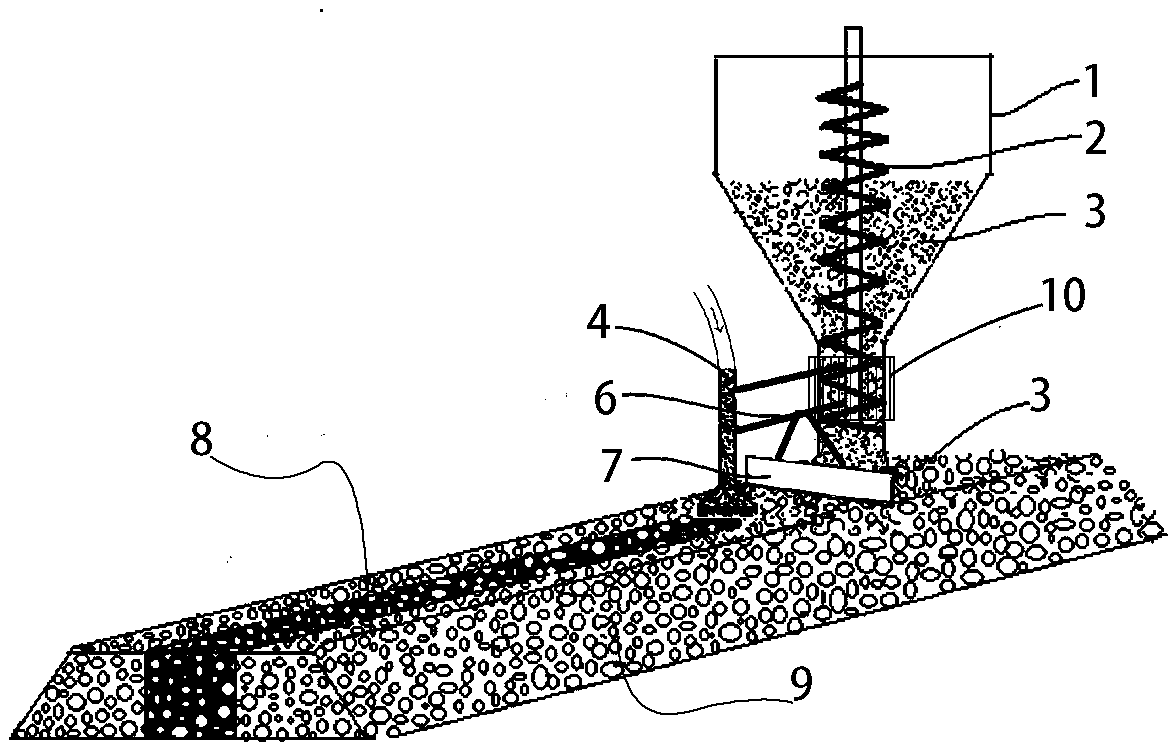

[0045] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention. Such as figure 1 and figure 2It is the first embodiment of the present invention, a 3D printing concrete forming equipment for stacking aggregate flow slurry, including a feeding system, a moving mechanism, a printing head and a control system, and the printing head includes a printing hopper 1 and a printing nozzle arranged vertically in parallel 4. The printing hopper 1 is equipped with a conveying screw blade 2; the printing nozzle 4 is equipped with a nozzle flow control valve. The nozzle flow control valve is not shown in the attached drawing and is directly controlled by the back-end slurry conveyor. The feeding of the printing hopper 1 The feeding port is connected with the feeding system of the aggregate 3, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com