PET anti-explosion film, anti-explosion glass rear cover and preparing process of anti-explosion glass rear cover

A technology of explosion-proof glass and explosion-proof film, which is applied in the direction of film/sheet adhesive, sub-office equipment, lamination, etc. It can solve the problems of poor mobile phone signal, discoloration of glass back cover, easy oxidation of electroplating layer, etc., and achieve good efficiency The effect of high efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

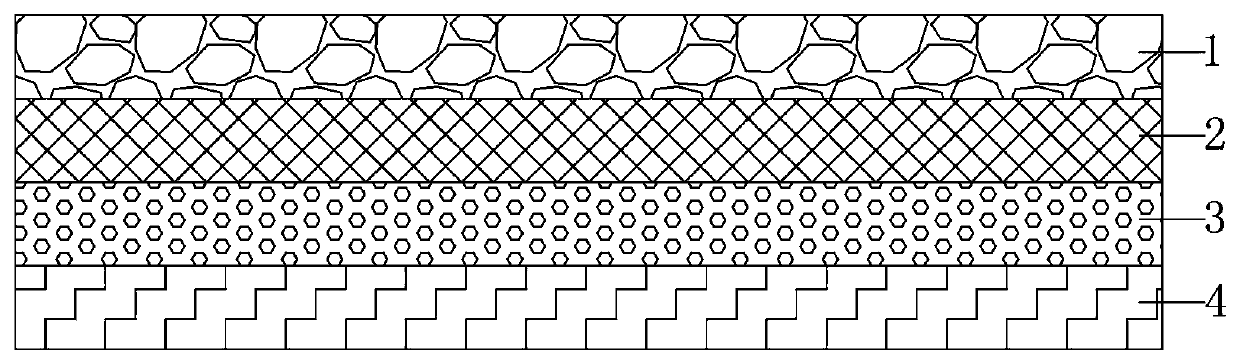

[0024] like figure 1 As shown, the first embodiment provided by the present invention, the PET explosion-proof film, includes an OCA optical adhesive layer 1 , a metallic luster PET base layer 2 , a UV transfer adhesive layer 3 and a printing layer 4 . The OCA optical adhesive layer 1 has a thickness of 20-30um; the metal luster PET base layer 2 is the PICASUS film of TORAY company or the blue light film of SKC company, and the thickness is 30-145um. Preferably, in the first embodiment, the OCA optical adhesive layer 1 has a thickness of 25 um, and the metal luster PET base layer 2 is a PICASUS film with a thickness of 70 um.

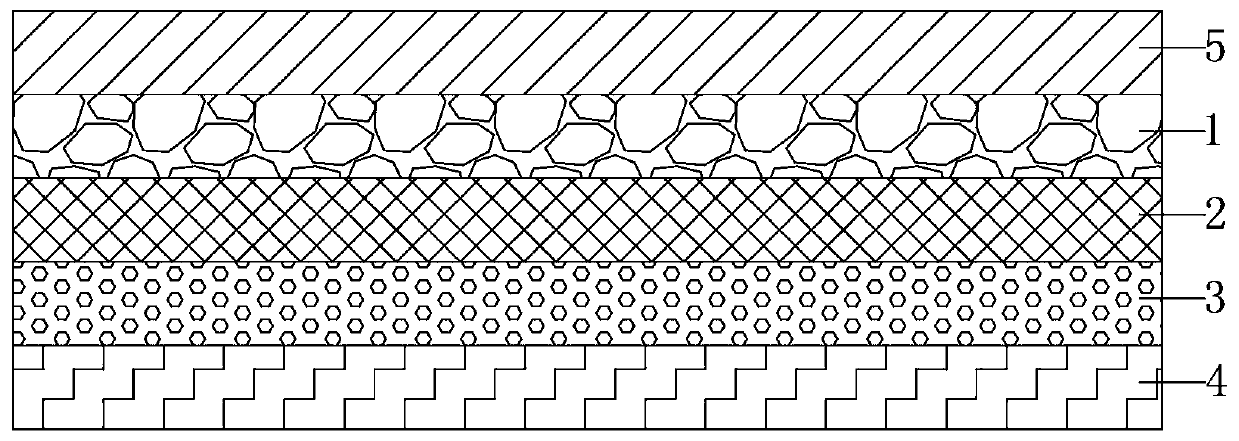

[0025] like figure 2 As shown, the second embodiment provided by the present invention, the explosion-proof glass rear cover, includes a glass cover plate 5 and a PET explosion-proof film as described in the first embodiment; the glass cover plate 5 is attached to the upper surface of the OCA optical adhesive layer 1 . The glass cover 5 is a 3D glas...

no. 3 example

[0026] The third embodiment provided by the present invention is a preparation process of the explosion-proof glass back cover as described in the second embodiment, the steps include: a. bonding the UV transfer adhesive layer 3 to the metallic luster PET through the UV transfer process The lower surface of the base layer 2; b. The printing layer 4 is formed on the lower surface of the UV transfer adhesive layer 3; c. On the roll-to-roll laminating machine, the light release film on the OCA optical adhesive layer 1 is peeled off by the waste discharge roller Finally, the OCA optical adhesive layer 1 is attached to the upper surface of the metallic luster PET base layer 2, and a PET explosion-proof film is obtained; d. the PET explosion-proof film is die-cut; e. the PET explosion-proof film and the The glass cover plate 5 is bonded together, and then degassed to obtain an explosion-proof glass rear cover.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com