Carbon black pelletizer

A granulator, carbon black technology, applied in the direction of extrusion granulation of raw materials, fibrous fillers, etc., can solve the problems of the quality decline of carbon black products, restricting the influence of carbon black, uneven carbon black particles, etc., and reducing the crushing rate. , not easy to break, improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

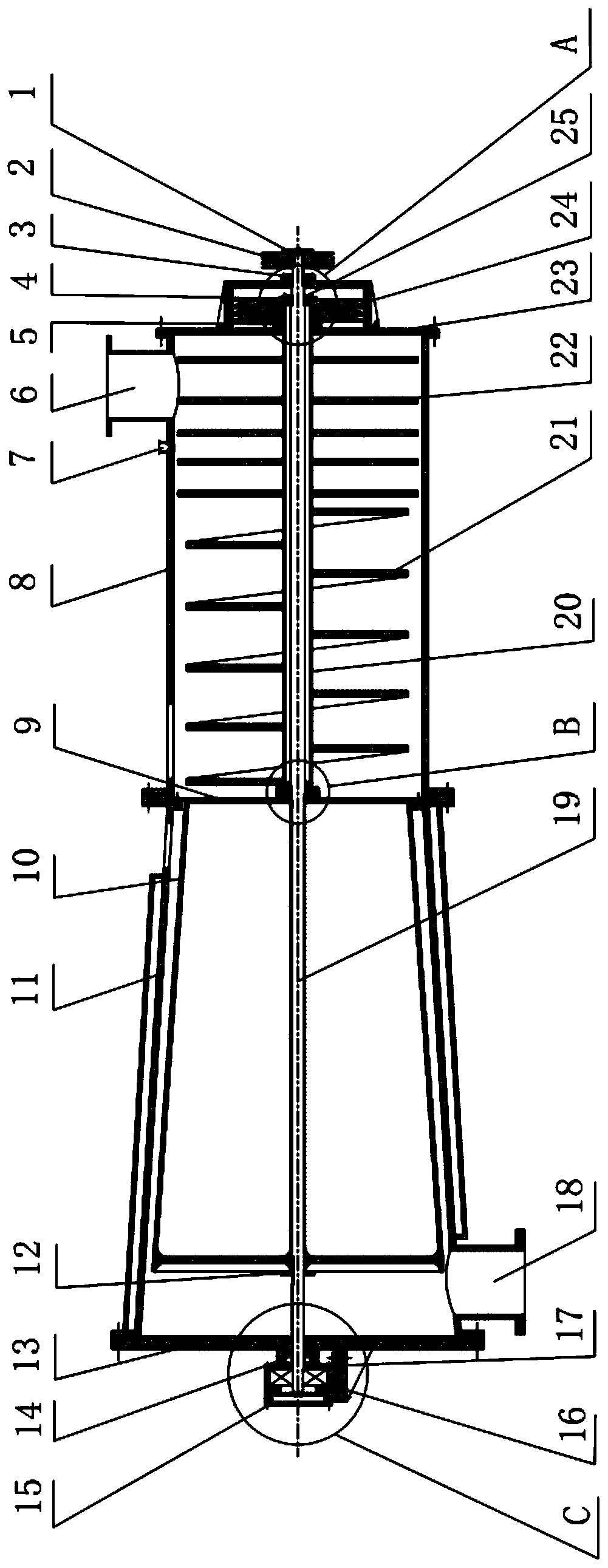

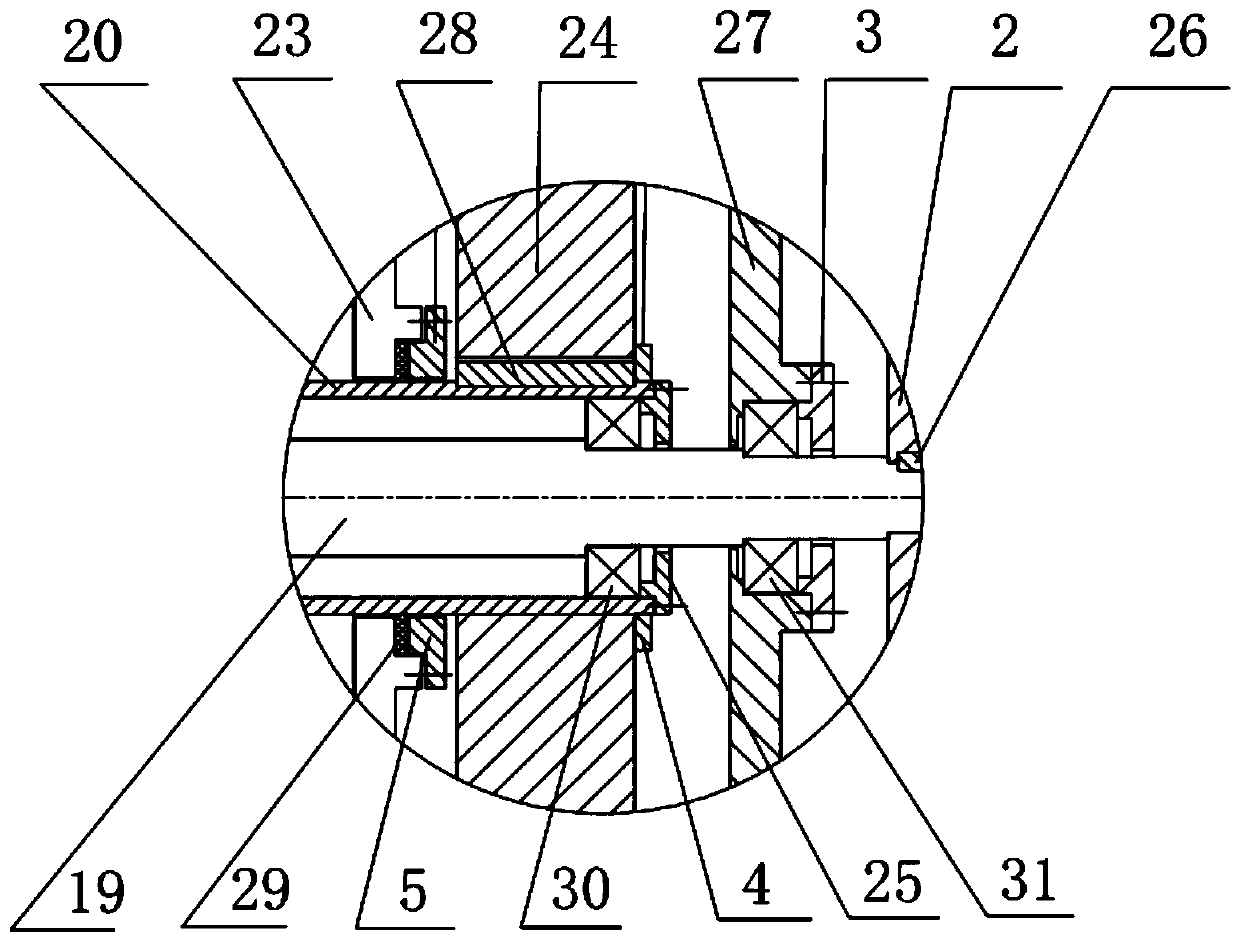

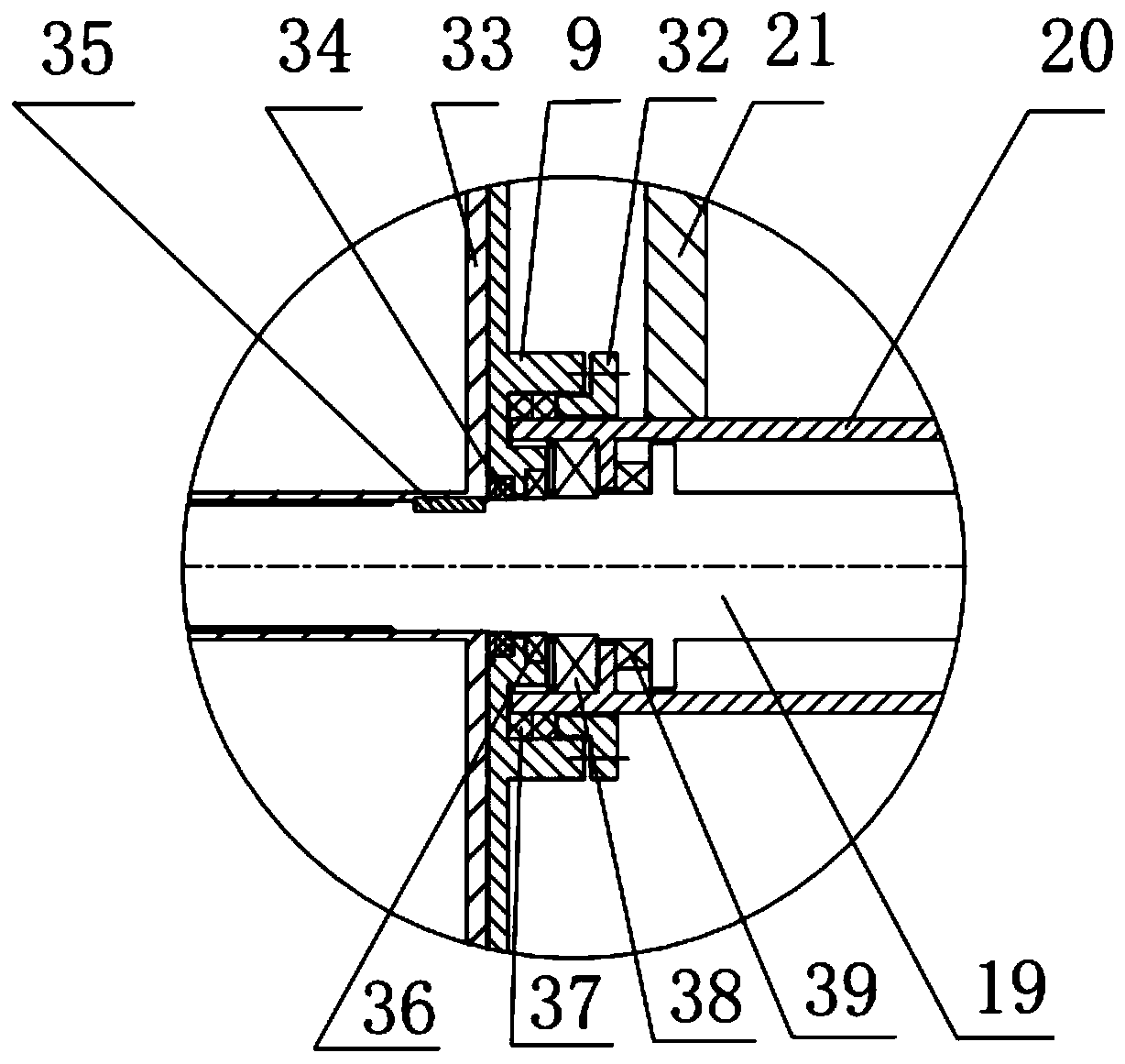

[0019] Such as Figure 1~6 As shown, a carbon black granulator of the present invention includes a cylindrical mixing extrusion section body 8 and a spheronizing drying section body 11, the front end of the mixing extrusion section body 8 is provided with a front cover 23, and the spheronizing drying section body 11 The rear end is provided with a rear cover plate 13, and the outer wall of the body 11 of the rounding drying section is also provided with a heating jacket. The body 8 of the mixing extrusion section and the body 11 of the rounding drying section are connected in the form of a flange and an orifice 9 is provided at the joint; for the convenience of installation or disassembly, the body 11 of the rounding drying section can be provided with a straight port, and the orifice 9 is fixed on the It's time to speak up. The orifice plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com