Preparation method of waterborne astigmatic screen paint

A preparation method and astigmatism technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of holes, clumps, insufficient screen imaging, and uneven distribution of astigmatism, so as to achieve balanced astigmatism and not easy to leak. The effect of holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

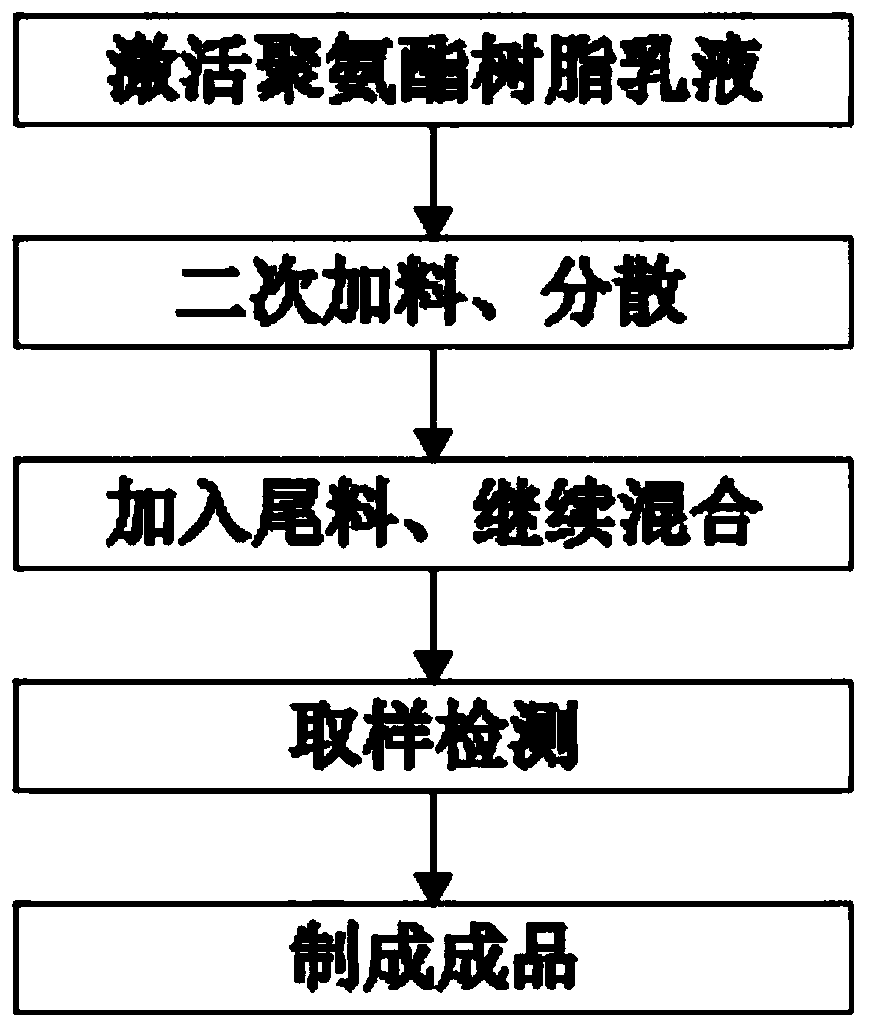

[0025] see figure 1 , the present invention provides a technical solution: a preparation method of water-based astigmatism screen coating, the formula of water-based astigmatism screen coating is respectively according to the mass proportion: 283 parts of polyurethane resin emulsion, 62 parts of light-scattering agent, 2.6 parts of fumed silica, moistening 2 parts of wet dispersant, 1.2 parts of leveling agent, 2 parts of OP-10, 1 part of defoamer, 3 parts of anti-sedimentation agent, 1.5 parts of antibacterial agent, 200 parts of deionized water, 3.2 parts of black resin, granules of astigmatism agent The diameter is 100-200nm, and the particle size of fumed silica is 100nm;

[0026] The wetting and dispersing agent is non-ionic wetting and dispersing agent, the leveling agent is BYK-333 type leveling agent, the defoamer is F126 type defoamer, and the anti-settling agent is BYK-420 type anti-settling agent;

[0027] The specific preparation method steps of the preparation me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com