A kind of electrothermal film based on graphene/iron oxide composite material and its preparation method

A composite material and graphene technology, which is applied in the direction of electric heating devices, ohmic resistance heating, heating element materials, etc., can solve the problem that the interaction is not fully displayed, and achieve the effect of enhanced scattering, saving process, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

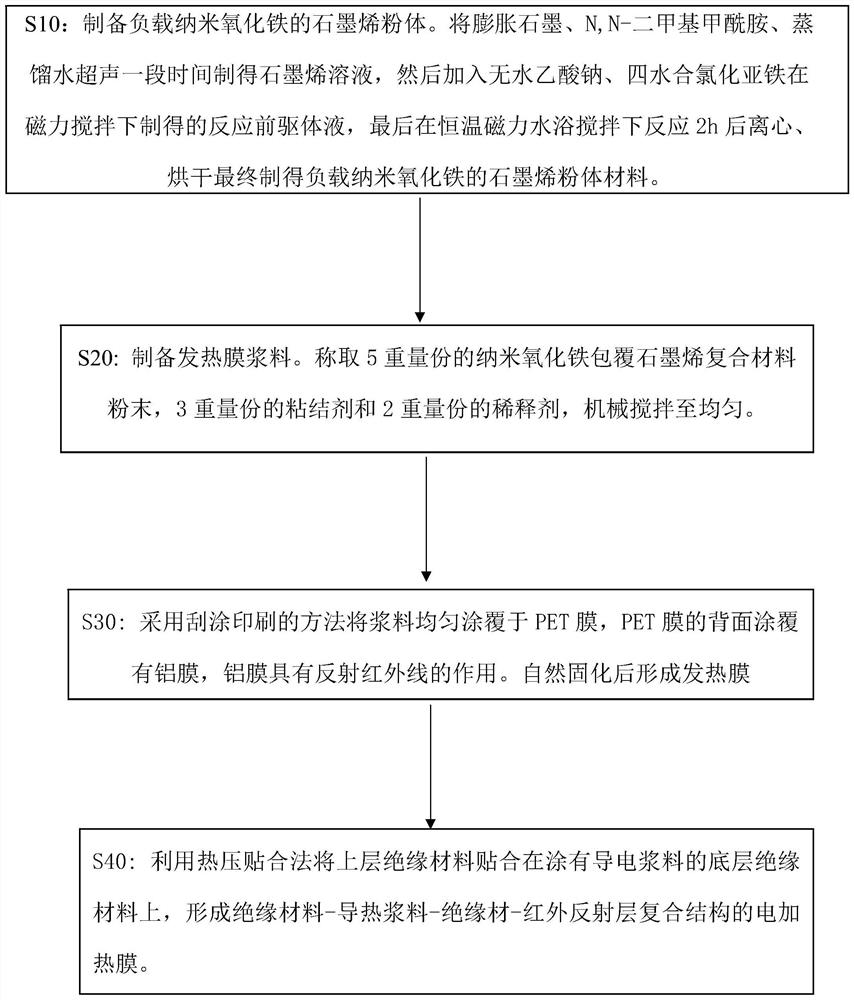

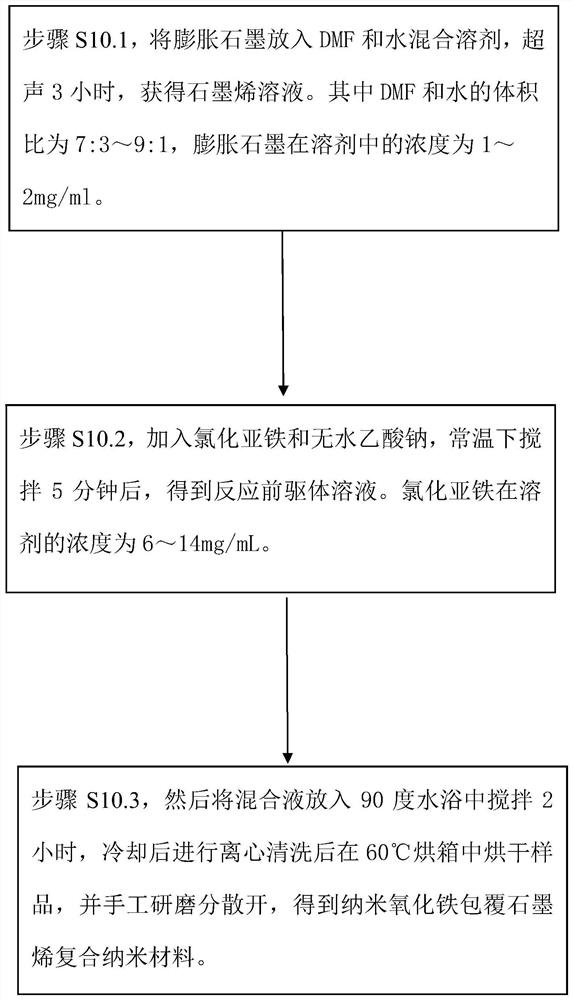

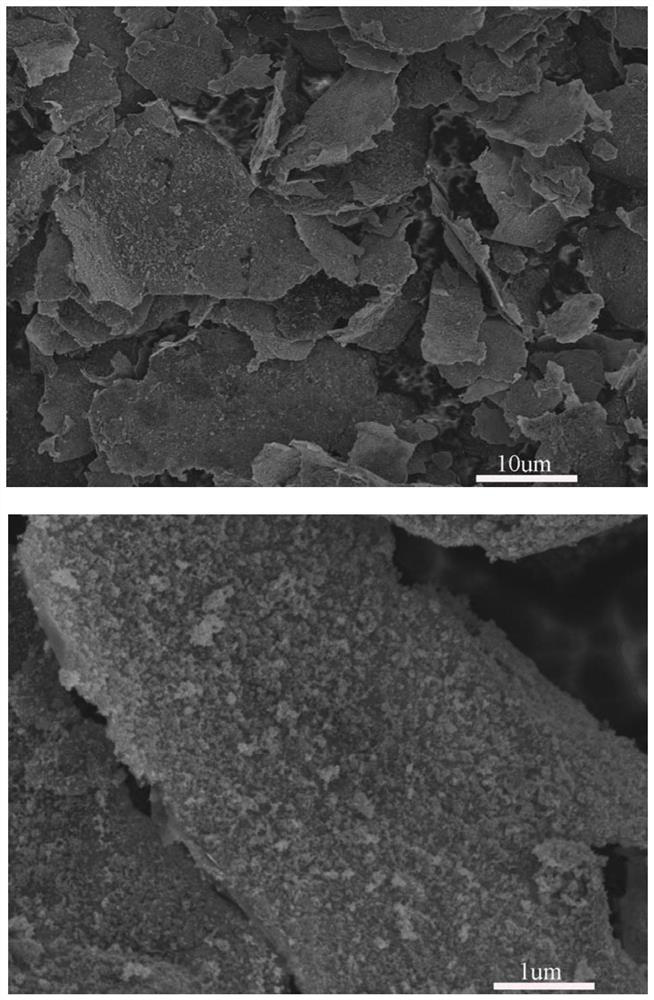

[0040] Preparation of nanometer iron oxide coated graphene powder. Put the expanded graphite into a mixed solvent of DMF and water, and sonicate for 3 hours to obtain a graphene solution. Add ferrous chloride, stir for 5 minutes at room temperature, then put the mixture in a 90-degree water bath and stir for 2 hours, after cooling, perform centrifugal cleaning, dry the sample in an oven at 60°C, and manually grind and disperse to obtain the load Graphene powder of nano iron oxide. The scanning electron microscope image of the composite material is shown in image 3 As shown, it can be seen that the nanoparticles evenly cover the graphene surface, the size of the nanoparticles is about 5nm, and the thickness of the nanoparticle film is basically the size of one particle. Wherein the volume ratio of DMF and water is 7:3. The concentration of ferrous chloride in the solvent is 14mg / mL, and the concentration of graphene in the solvent is 2mg / ml. image 3 The SEM images of diff...

Embodiment 2

[0046] Preparation of nanometer iron oxide coated graphene powder. Put the expanded graphite into a mixed solvent of DMF and water, and sonicate for 3 hours to obtain a graphene solution. Add ferrous chloride, stir for 5 minutes at room temperature, then put the mixture in a 90-degree water bath and stir for 2 hours, after cooling, perform centrifugal cleaning, dry the sample in an oven at 60°C, and manually grind and disperse to obtain the load Graphene powder of nano iron oxide. Wherein the volume ratio of DMF and water is 8:2. The concentration of ferrous chloride in the solvent is 10mg / mL, and the concentration of graphene in the solvent is 1.5mg / ml.

[0047] Prepare the heat-generating film slurry. Weigh 5 parts by weight of nano-iron oxide coated graphene powder, 3 parts by weight of binder and 2 parts by weight of diluent. Wherein the binder is acrylic acid resin, and the diluent can be a special acrylic resin diluent or ethyl acetate. Stir mechanically until homog...

Embodiment 3

[0051] Preparation of nanometer iron oxide coated graphene powder. Put the expanded graphite into a mixed solvent of DMF and water, and sonicate for 3 hours to obtain a graphene solution. Add ferrous chloride, stir for 5 minutes at room temperature, then put the mixture in a 90-degree water bath and stir for 2 hours, after cooling, perform centrifugal cleaning, dry the sample in an oven at 60°C, and manually grind and disperse to obtain the load Graphene powder of nano iron oxide. Wherein the volume ratio of DMF and water is 9:1. The concentration of ferrous chloride in the solvent is 6mg / mL, and the concentration of graphene in the solvent is 1mg / ml.

[0052] Prepare the heat-generating film slurry. Weigh 5 parts by weight of nano-iron oxide coated graphene powder, 3 parts by weight of binder and 2 parts by weight of diluent. Wherein the binder is acrylic acid resin, and the diluent can be a special acrylic resin diluent or ethyl acetate. Stir mechanically until homogene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com