A kind of preparation method of composite solid electrolyte and its products

A solid electrolyte and electrolyte technology, applied in solid electrolyte, non-aqueous electrolyte, circuit, etc., can solve the problems of unsatisfactory room temperature conductivity and no ability to transmit lithium ions, so as to improve mechanical strength and ion conductivity, and solve the problem of lithium branch Crystal growth and the effect of reducing crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

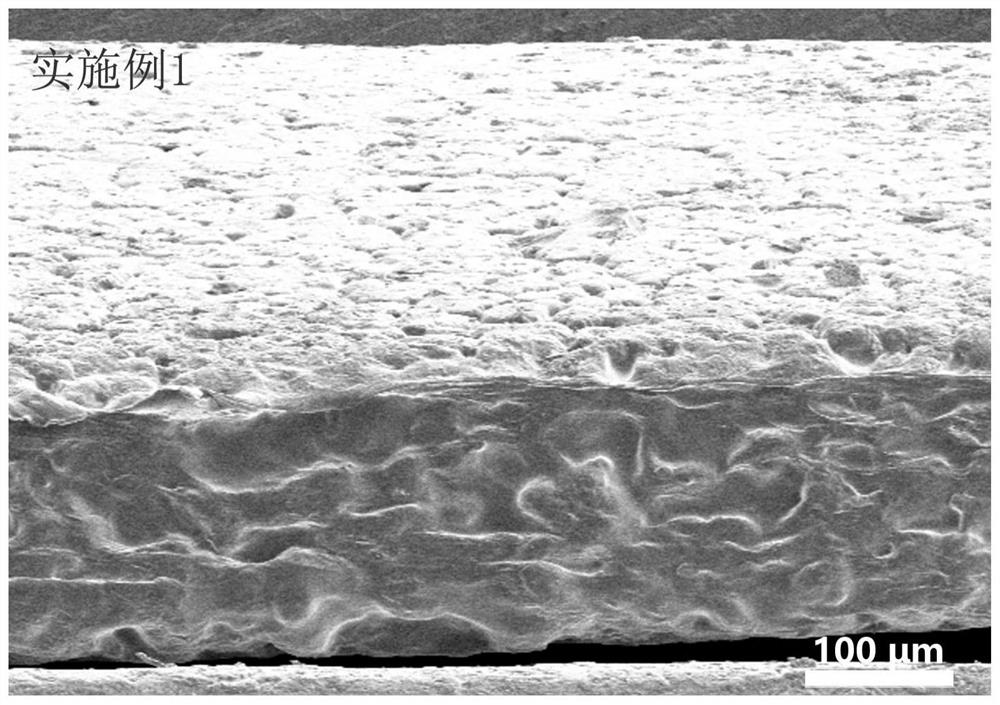

Embodiment 1

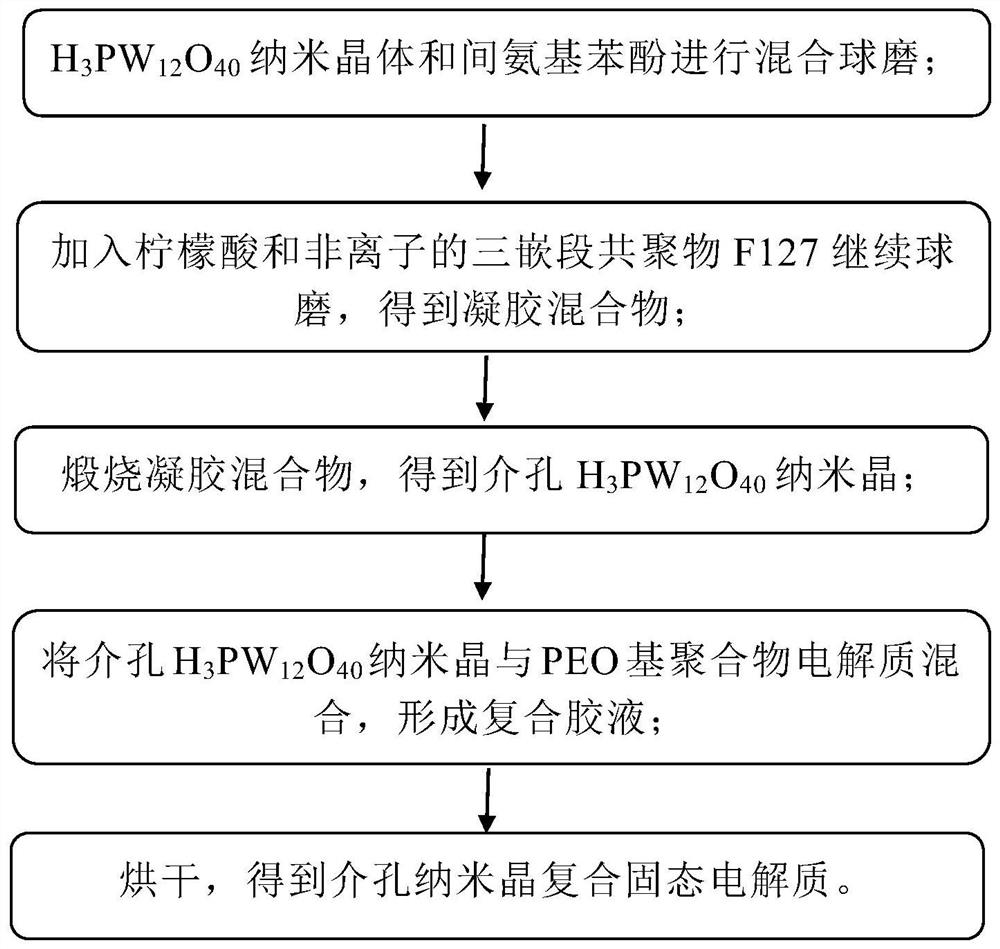

[0027] A method for preparing a composite solid electrolyte, comprising the following steps:

[0028] S1, H 3 PW 12 o 40 Preparation of nanocrystals: 1 kg of Na 2 WO 4 2H 2 O was dissolved in 1 L of deionized water, heated to boiling until the solution was clear, and then 100 mL of 85% H 3 PO 4 , then slowly add 800mL of concentrated hydrochloric acid to the solution, and then add 600mL of anhydrous ether to the solution to continue mixing after the solution is cooled, shake well, so that the mixed solution is divided into three layers, and then the bottom solution is transferred out, And wash the remaining solution with water several times; finally make it heated and evaporated to obtain, H 3 PW12 o 40 nanocrystals;

[0029] S2, the H 3 PW 12 o 40 Nanocrystals and m-aminophenol were added to a zirconia ball mill jar at a mass ratio of 5:1, milled for 20 minutes, and then an appropriate amount of citric acid and nonionic tri-block copolymer F127 was added to contin...

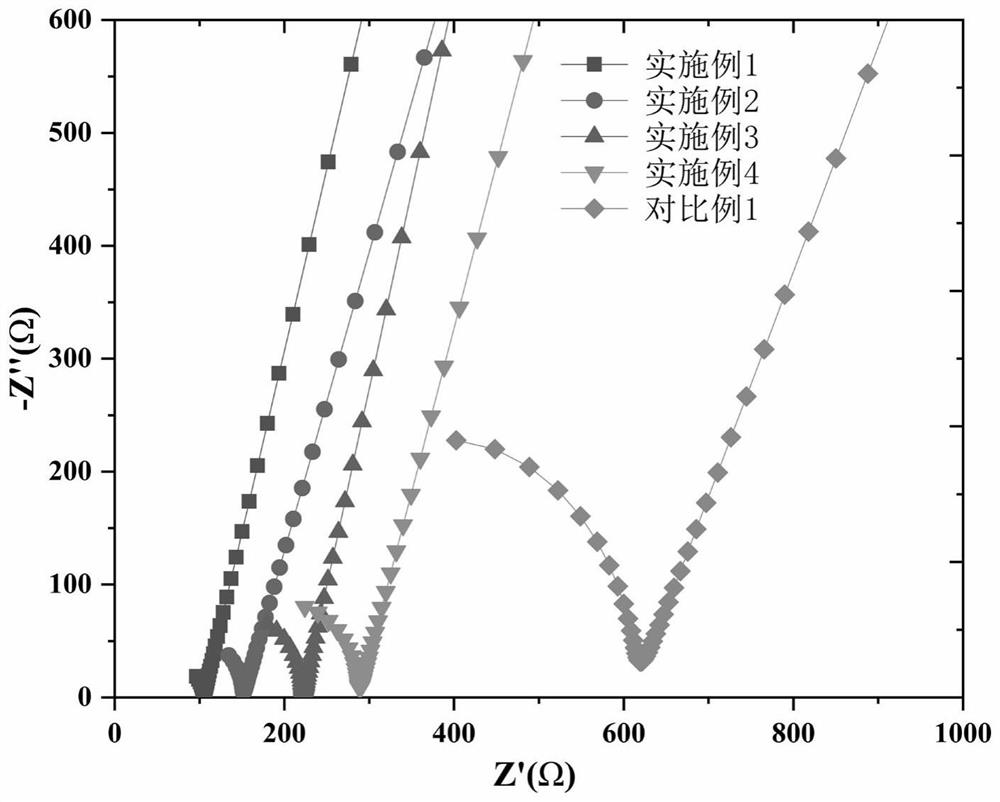

Embodiment 2

[0035] The difference from Example 1 is that mesoporous H 3 PW 12 o 40 The mass ratio of nanocrystals to PEO-based polymer electrolyte is the mesoporous H of this embodiment 3 PW 12 o 40 The mass of nanocrystals added is 34.05g (20wt%).

[0036] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0038] The difference from Example 1 is that mesoporous H 3 PW 12 o 40 The mass ratio of nanocrystals to PEO-based polymer electrolyte is the mesoporous H of this embodiment 3 PW 12 o 40 The mass of nanocrystals added is 58.37g (30wt%).

[0039] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com