Chromium-containing wastewater treatment system using water column generation absorption principle

A treatment system, chromium wastewater treatment technology, applied in the direction of metallurgical wastewater treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of large clogging, reduced filter life, poor chromium collection effect, etc., to achieve Avoid clogging, solve bottom condensation, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

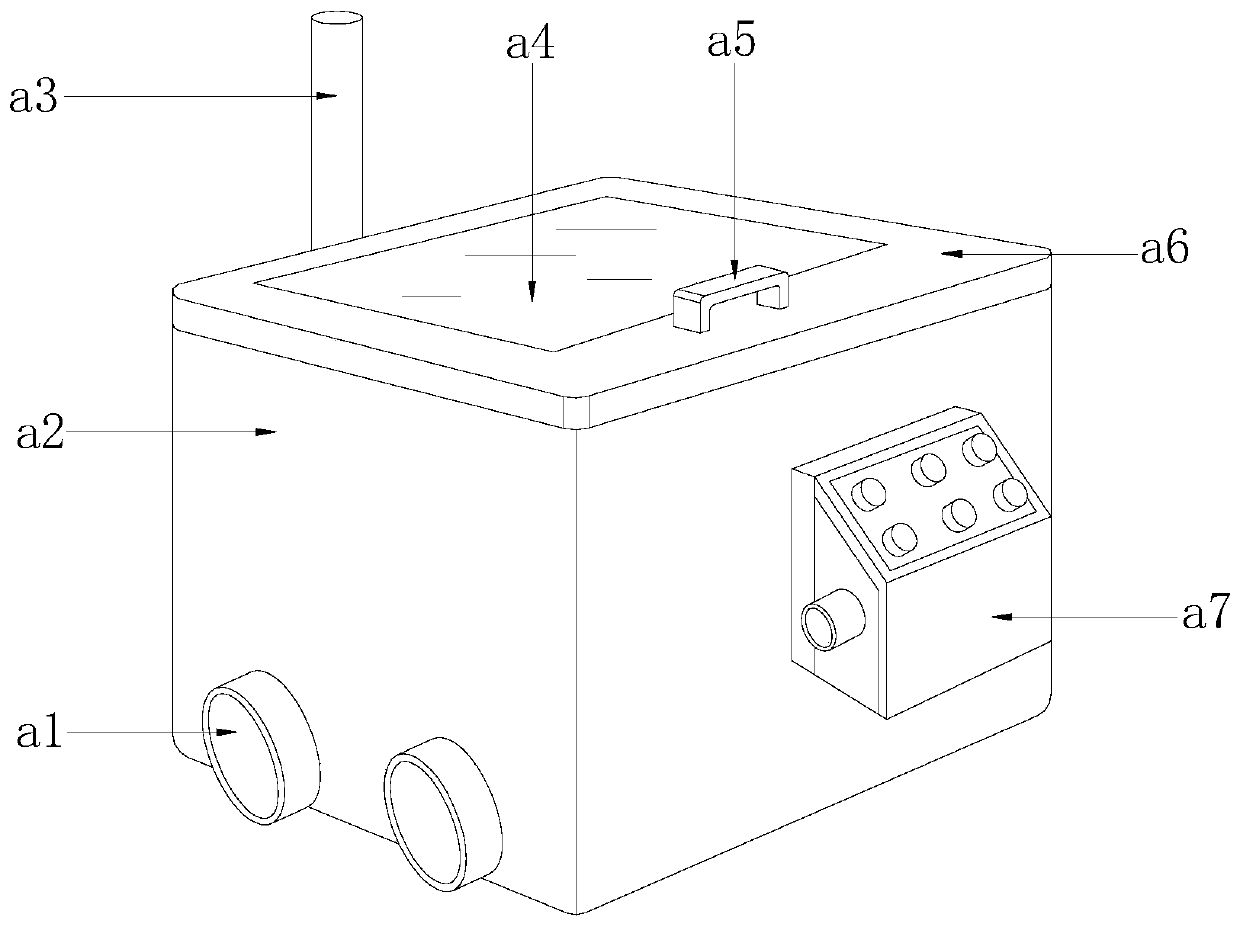

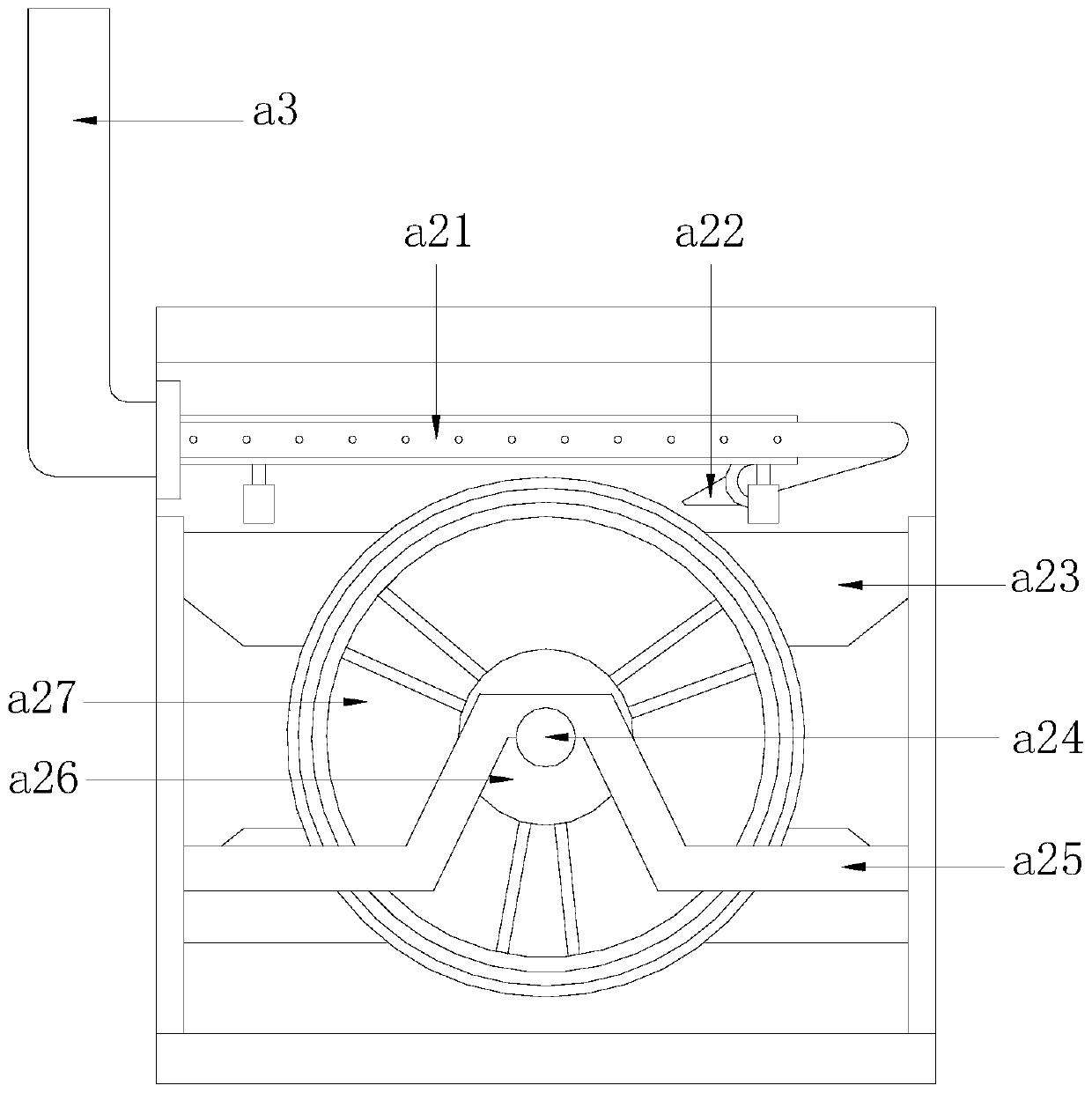

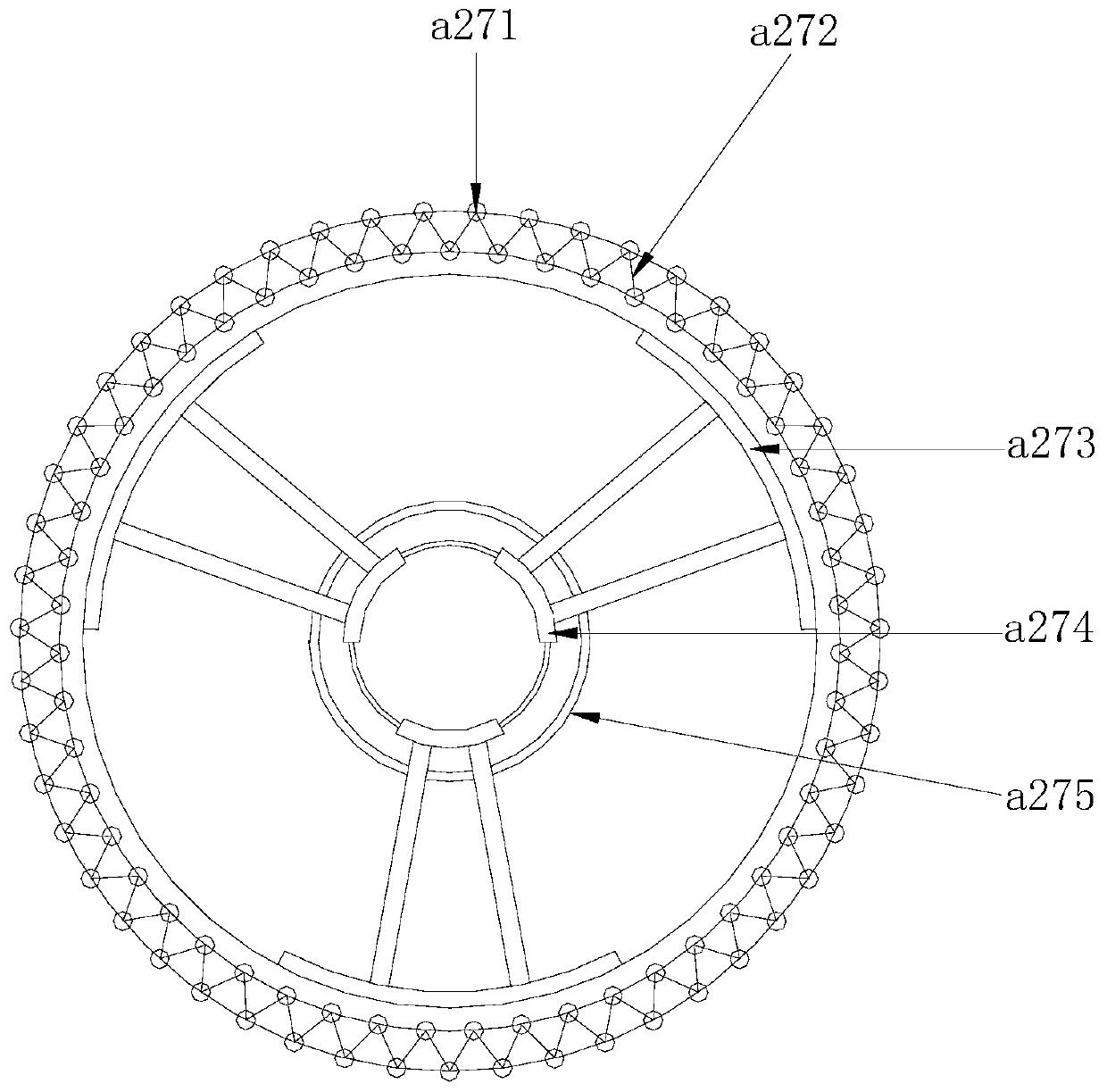

[0030] see Figure 1-Figure 7 , the present invention provides a chromium-containing wastewater treatment system using the principle of water column generation and absorption, the structure of which includes a water outlet a1, a filter box a2, a water inlet a3, an observation port a4, a convenient handle a5, a sealing cover a6, and a controller a7. The controller a7 is installed in the middle of the front end of the filter box a2 by buckling, and the lower left side of the filter box a2 is provided with two water outlets a1, and the sealing cover a6 is installed on the top of the filter box a2 by buckling. The rear end of the filter box a2 is provided with a water inlet a3, the observation port a4 is a rectangular structure, and is installed in the middle of the sealing cover a6, the front end of the sealing cover a6 is provided with a convenient handle a5, and the water inlet a3 is used to connect sewage The discharge equipment is further introduced into the filter box a2 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com