Closed S-shaped grain conveying dust removing device

A dust removal device, a closed technology, applied in the direction of solid separation, separating solids from solids with airflow, chemical instruments and methods, etc., can solve the problem of dust removal, impurity removal, debris and dust flying around, hot air pressure Large and other problems, achieve good dust removal effect, prolong the transportation time, and reduce the volume of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

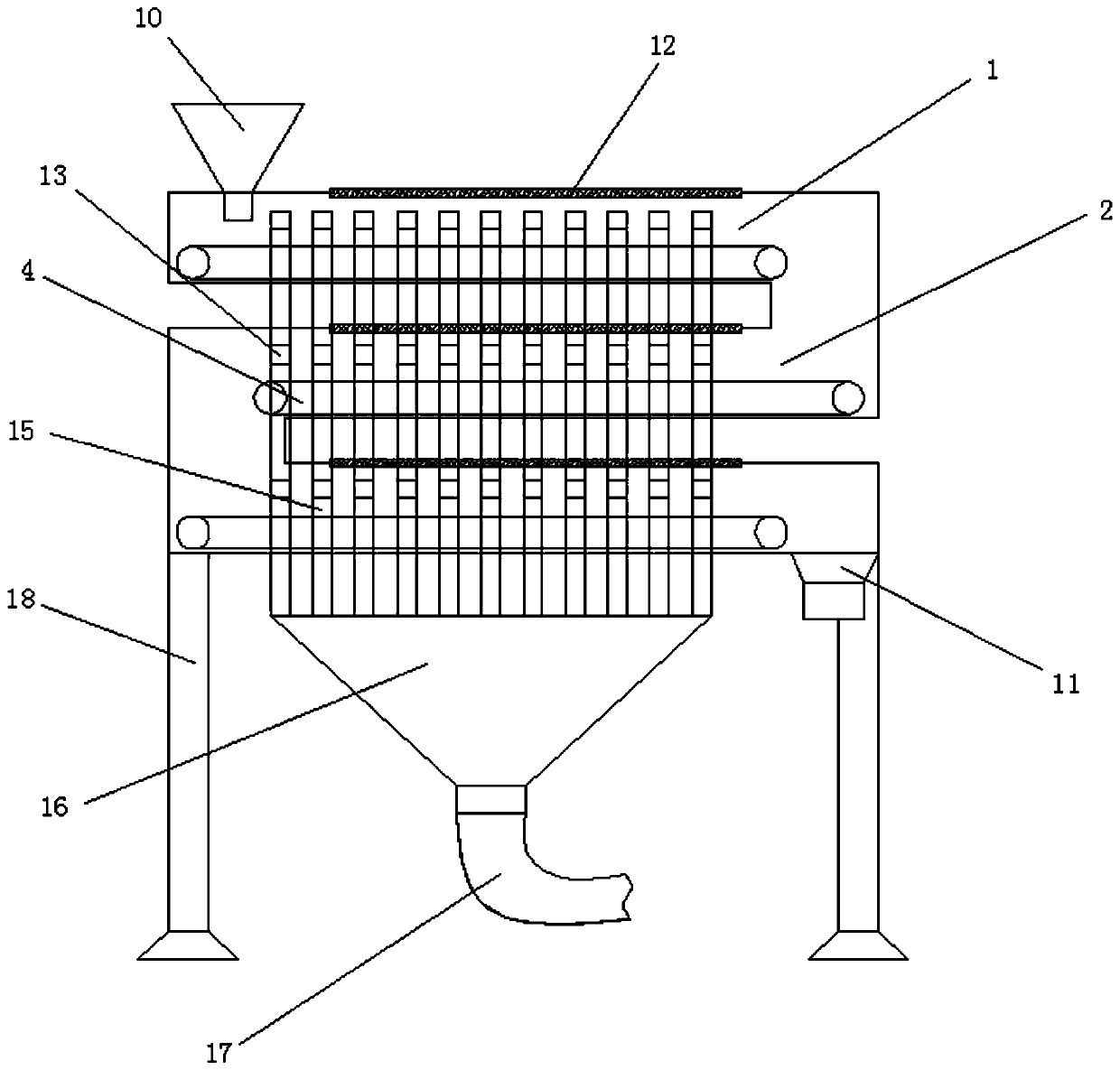

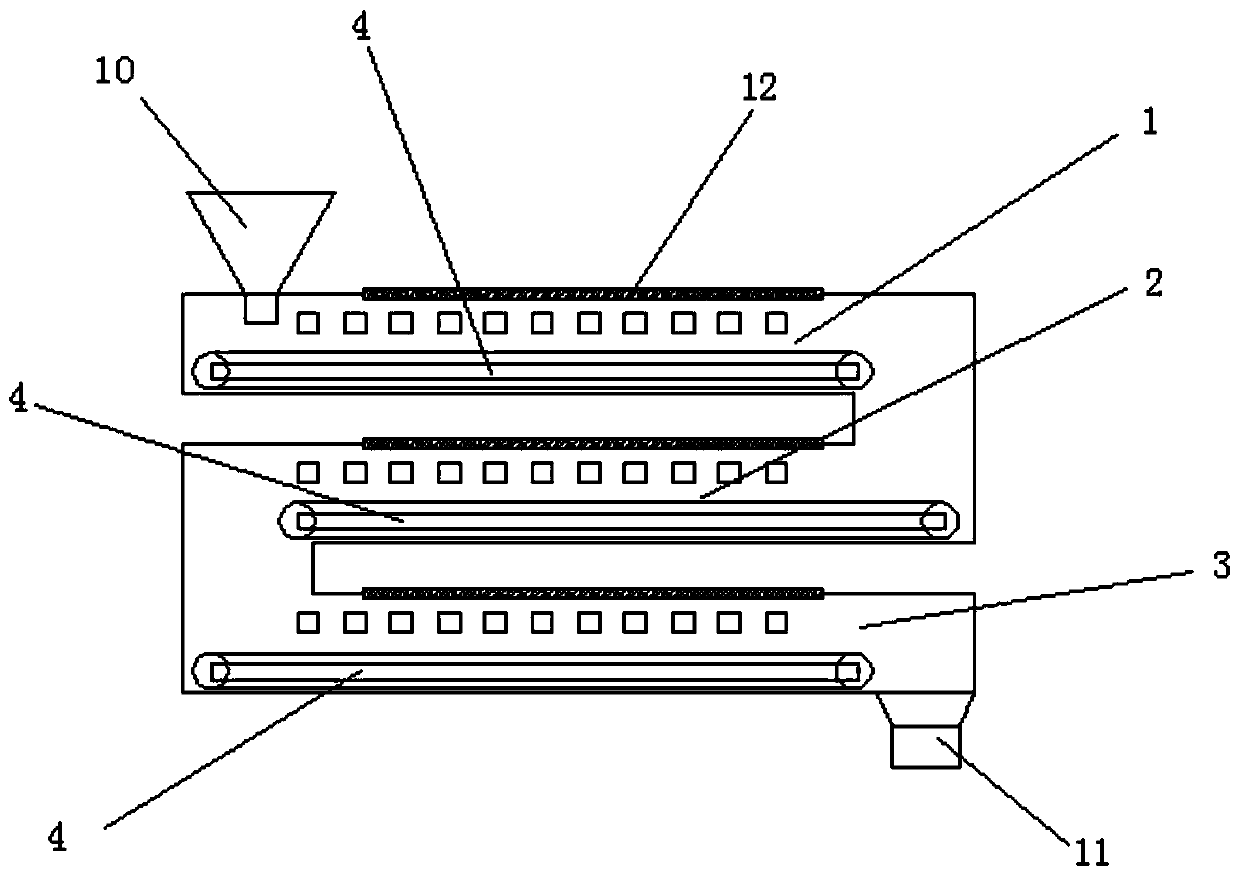

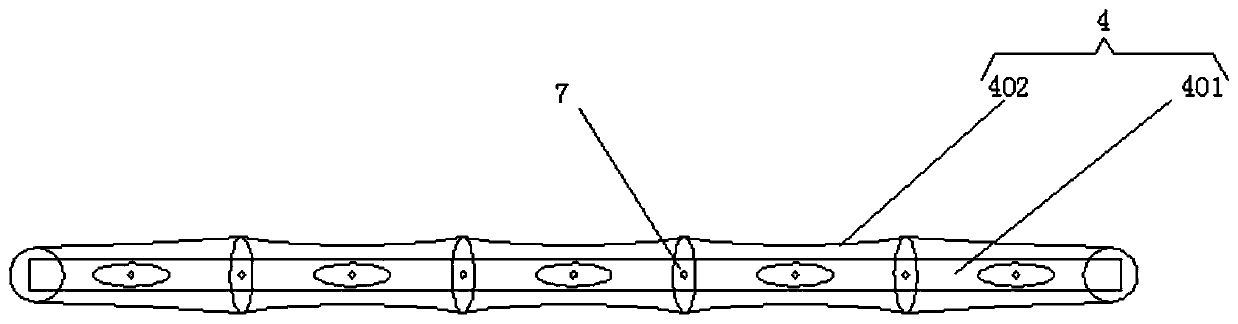

[0035] Embodiment 1: as Figure 1-7 As shown, a closed S-shaped grain conveying dust removal device includes a first dust removal bin 1, a second dust removal bin 2 and a third dust removal bin 3, the right bottom of the first dust removal bin 1 is connected to the second dust removal bin 2 The right top of the second dust removal bin 2 is connected to the left top of the third dust removal bin 3 to form an S-shaped sealed chamber. The left side of the first dust removal bin 1 A feed hopper 10 is fixedly installed on the top, and a discharge hopper 11 is fixedly installed on the bottom right side of the third dust removal bin 3. The tops of the first dust removal bin 1, the second dust removal bin 2 and the third dust removal bin 3 are all opened There is an air inlet 12, and four sets of feet 18 are fixedly installed on the bottom of the third dust removal bin 3; the three sets of dust removal bins are folded and set, which can reduce the volume of the device, prolong the tim...

Embodiment 2

[0043] Embodiment 2: as Figure 1-10 As shown, a closed S-shaped grain conveying dust removal device includes a first dust removal bin 1, a second dust removal bin 2 and a third dust removal bin 3, the right bottom of the first dust removal bin 1 is connected to the second dust removal bin 2 The right top of the second dust removal bin 2 is connected to the left top of the third dust removal bin 3 to form an S-shaped sealed chamber. The left side of the first dust removal bin 1 A feed hopper 10 is fixedly installed on the top, and a discharge hopper 11 is fixedly installed on the bottom right side of the third dust removal bin 3. The tops of the first dust removal bin 1, the second dust removal bin 2 and the third dust removal bin 3 are all opened There is an air inlet 12, and four sets of feet 18 are fixedly installed on the bottom of the third dust removal bin 3; the three sets of dust removal bins are folded and set, which can reduce the volume of the device, prolong the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com