Connection failure detection method of power battery pack and battery management system

A power battery pack and connection failure technology, applied in battery/fuel cell control devices, measuring electricity, electric vehicles, etc., can solve the problems of inability to judge and prevent high-voltage busbars, and achieve the effects of avoiding local heat generation and low detection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments and features in the embodiments of the present invention can be combined with each other.

[0025] The present invention will be described in detail below with reference to the drawings and in combination with embodiments.

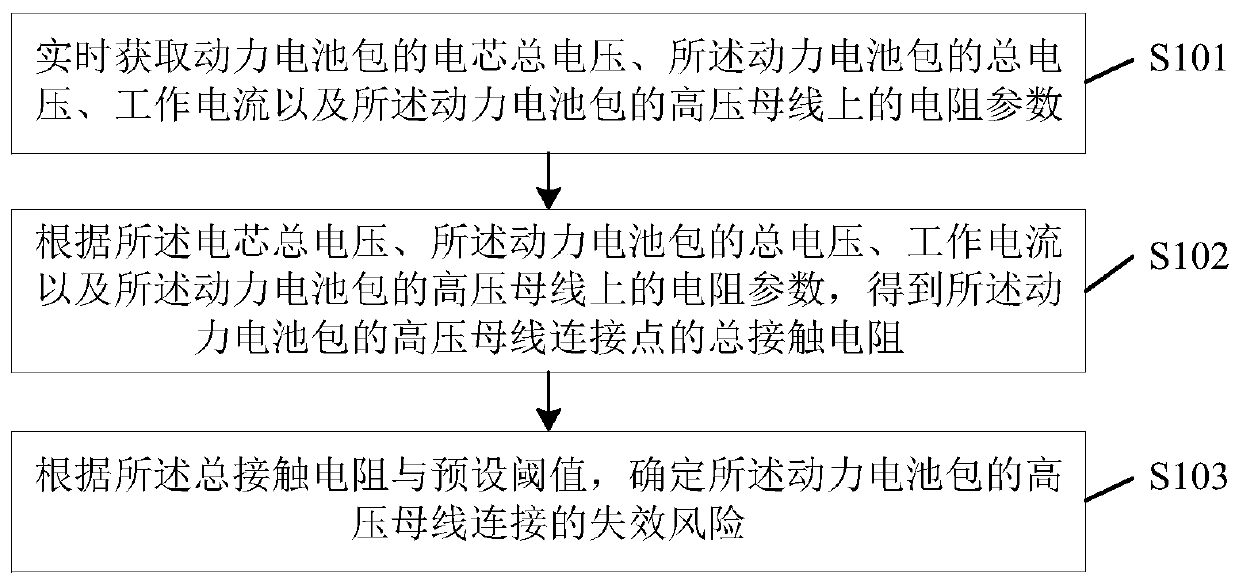

[0026] figure 1 It is a schematic flowchart of a method for detecting connection failure of a power battery pack provided by an embodiment of the present invention. Such as figure 1 As shown, the method is applied to the BMS, and the connection failure detection method of the power battery pack includes the following steps:

[0027] Step S101, obtaining in real time the total voltage of the cells of the power battery pack, the total voltage of the power battery pack, the working current, and the resistance parameters on the high-voltage bus of the power battery pack;

[0028] Step S102, according to the total voltage of the battery cell, the total voltage of the power battery pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com