Rubber glove drying system utilizing solar heat pump

A technology of solar heat pump and rubber gloves, applied in solar heating systems, solar thermal energy, solar thermal power generation, etc., can solve the problems of uneven heating of gloves, difficult temperature control, low drying efficiency, etc., to achieve repeated use and easy control. , the effect of high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

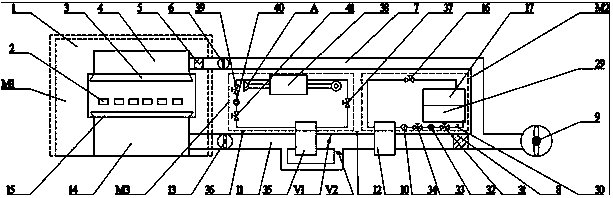

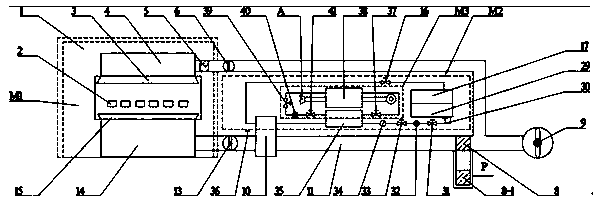

[0024] Implementation case 1: When the sunlight is sufficient, the water temperature in the solar collector reaches the set temperature, and the heat pump can heat the air to the temperature required for drying rubber gloves without turning on. The dry and high-temperature air is sent to the air outlet by the air supply fan, and after heat and moisture exchange with the rubber gloves on the hand mold 2 in the drying room 1, it becomes hot and humid air, which passes through the air outlet 3 through the action of the return air fan 6 Enter the exhaust box 4, then enter the return air processing section 5, and enter the air supply processing section 8 through the return air pipe section 7. The return air treatment section has two main functions. One is to filter the dust generated during the drying process of rubber gloves to avoid secondary pollution of the rubber gloves by the dust, and to avoid dust in the return air attached to the heat exchanger in the heat pump system, On ...

Embodiment example 2

[0026] Implementation case 2: When the light is insufficient, the water temperature in the solar collector does not reach the set temperature. When the solar collector system is turned on, the heat pump system is turned on, and the air is heated to the temperature required for drying rubber gloves and then sent to the drying oven. house.

[0027] The dry and high-temperature air is sent to the air outlet by the air supply fan, and after heat and moisture exchange with the rubber gloves on the hand mold 2 in the drying room 1, it becomes hot and humid air, which passes through the air outlet 3 through the action of the return air fan 6 Enter the exhaust box 4, then enter the return air processing section 5, and enter the air supply processing section 8 through the return air pipe section 7. The return air treatment section has two main functions. One is to filter the dust generated during the drying process of rubber gloves to avoid secondary pollution of the rubber gloves by t...

Embodiment example 3

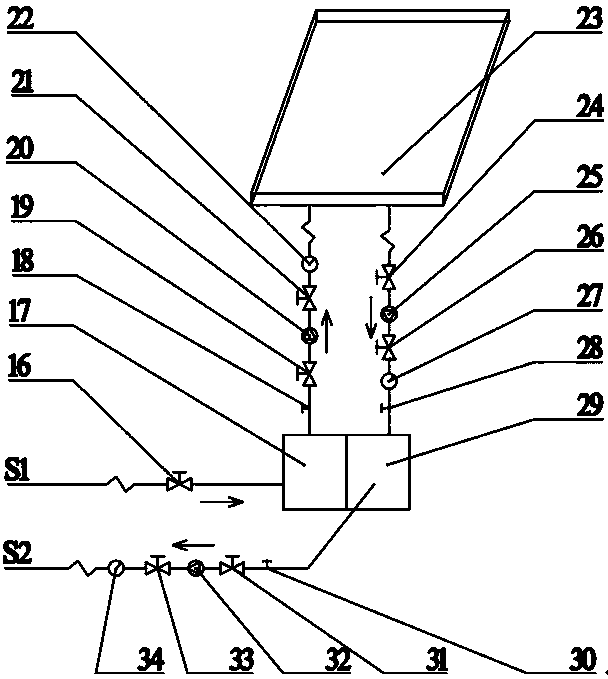

[0030] Implementation case 3: The working principle diagram of the system is as follows figure 2 shown. When the light is insufficient, the water temperature in the solar collector does not reach the set temperature. When the solar collector system is turned on, the heat pump system is turned on. The heat pump system and the solar collector system heat the water successively, and then heat the air through the hot water. To the temperature required for drying rubber gloves and then sent to the drying room.

[0031] The dry and high-temperature air is sent to the air outlet by the air supply fan, and after heat and moisture exchange with the rubber gloves on the hand mold 2 in the drying room 1, it becomes hot and humid air, which passes through the air outlet 3 through the action of the return air fan 6 Enter the exhaust box 4, then enter the return air processing section 5, and enter the air supply processing section 8 through the return air pipe section 7. The return air t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com