Device and method for measuring density of water and rock debris mixture at different water levels in blasthole

A technology for mixtures and cuttings, applied in measuring devices, specific gravity measurement, instruments, etc., can solve problems such as the influence of blasting parameters, and achieve the effects of controlling hazards, strong operability, and saving investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

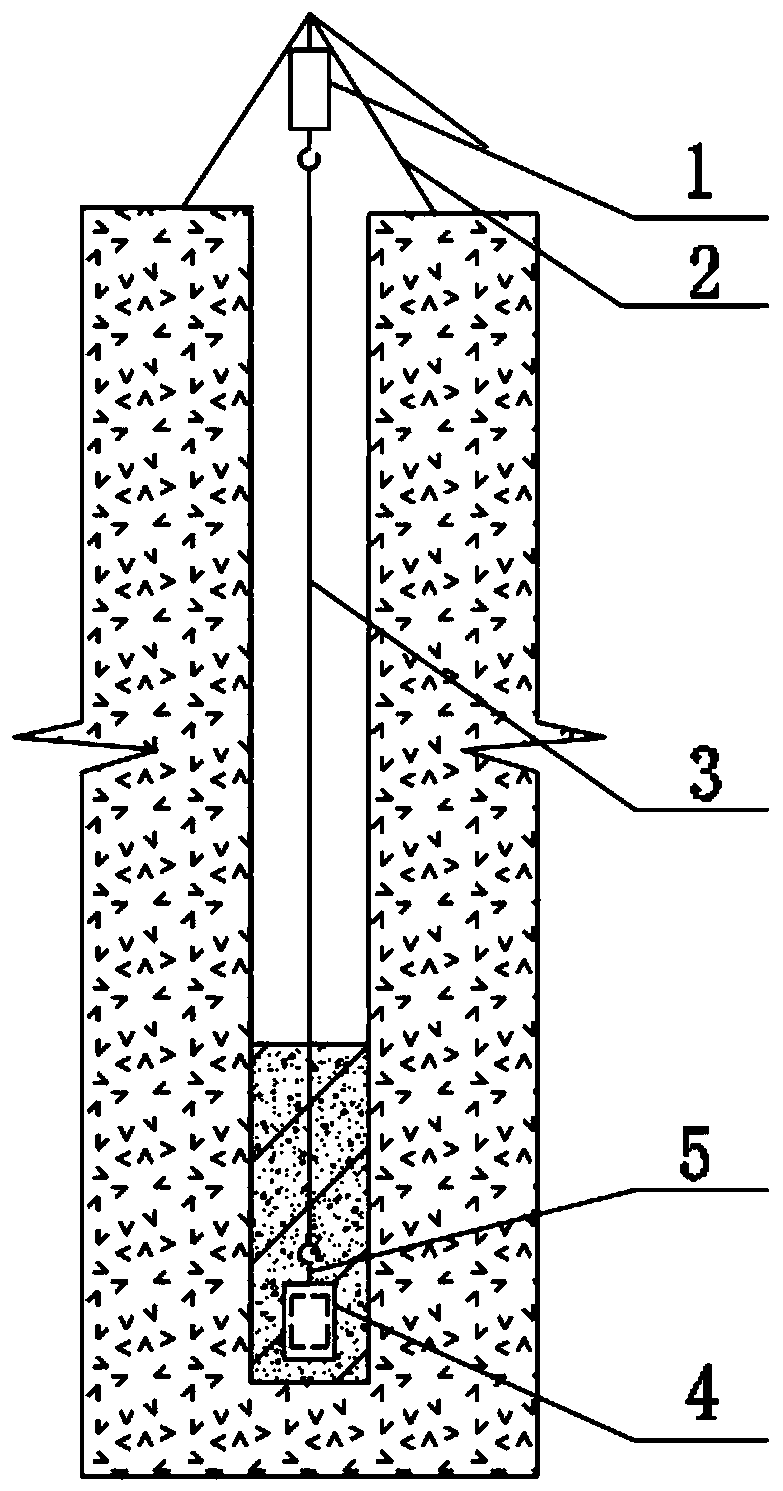

[0022] Embodiment 1: as Figure 1-3 As shown, a device for measuring the density of the mixture of water and rock debris at different water levels in the blasthole, including a tripod 2, a nylon rope 3, a hollow iron block 4 and a spring dynamometer 1,

[0023] The upper end of the spring dynamometer is fixed on the tripod 2 by a rope, the lower end of the spring dynamometer 1 is connected with the nylon rope 3, and the lower end of the nylon rope 3 is connected with it by the hook 5 on the hollow iron block 4; The meter 1 is fixed on the tripod 2 to ensure that the reading of the spring dynamometer 1 can be stable and the measured data are more accurate. In addition, the nylon rope 3 is light and hard, has low water absorption and good dimensional stability; its weight and other factors have little influence on the results, which can be almost ignored.

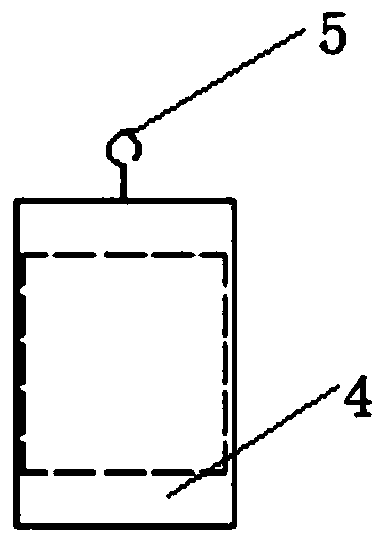

[0024] Described hollow iron block 4 comprises a sealed cylindrical shell, and its inside is provided with a hollow cylind...

Embodiment 2

[0025] Embodiment 2: adopt the device as described in embodiment 1 in the present embodiment to measure the density of water and cuttings mixture under different water levels in the blast hole,

[0026] To make the hollow iron block 4 sinkable in the mixture of water and cuttings, it is necessary to ensure that G>F f Namely: v 实 / v>ρ / ρ 铁 , where v 实 Be the volume of the cylindrical shell that is the solid part of the hollow iron block 4, and ρ is the density of the mixture of water and cuttings. In the present embodiment, the radius of the bottom surface of the cylindrical shell in the hollow iron block 4 is R=15mm, and the hollow iron block 4 The height H=45mm of cylinder shell, the bottom surface radius r=14.23mm of the hollow cylinder in the hollow iron block 4, the height h=30mm of the hollow cylinder in the hollow iron block 4, utilize formula G=(πR 2 H-πr 2 h) ρ 铁 g, ρ 铁 =7.9×10 3 kg / m 3 , obtain the gravity G=0.98N of the hollow iron block 4;

[0027] Record th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com