Reclaiming method and reclaiming device of destrutive distilled oil gas of block moving bed

A recovery method and moving bed technology, which are applied in the field of massive moving bed dry distillation oil gas recovery method and its recovery device, can solve the problems of high value-added light oil loss, easy oil decomposition, pipeline blockage, etc., and achieve improved dry distillation production Oil rate, less oil and gas dust, and improved recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

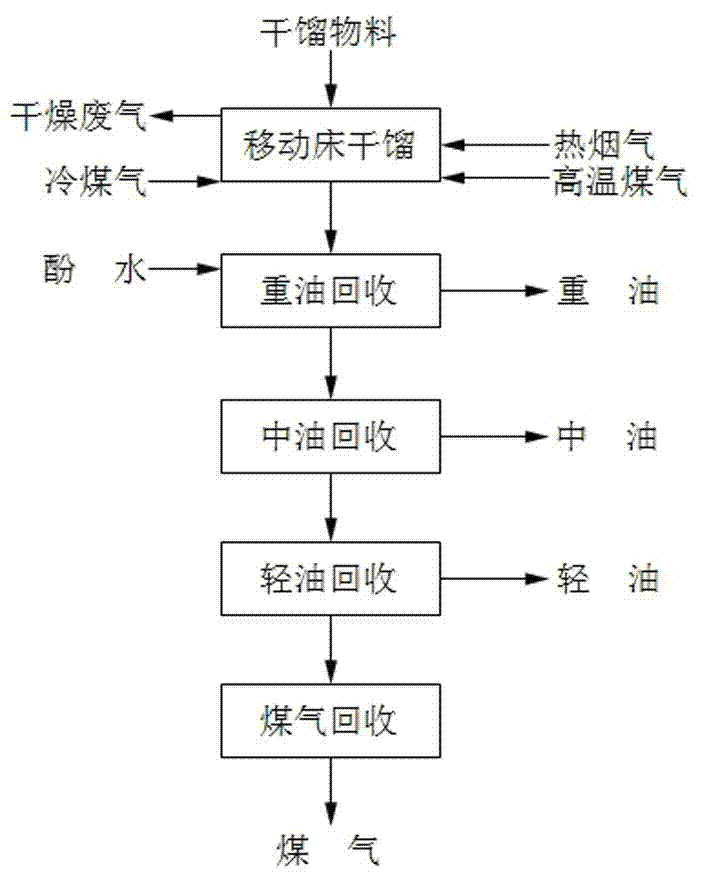

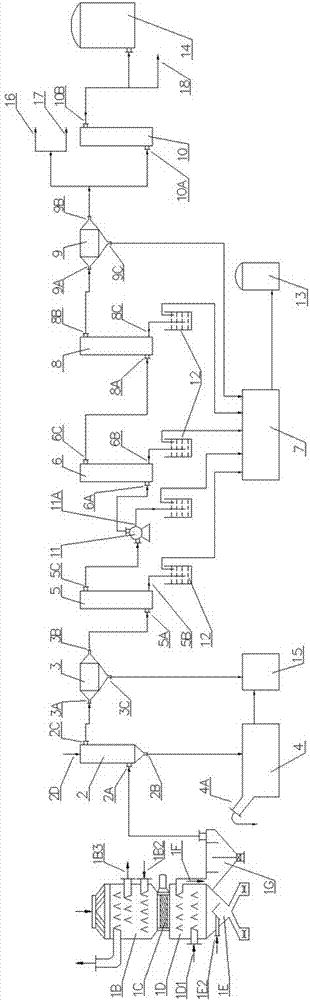

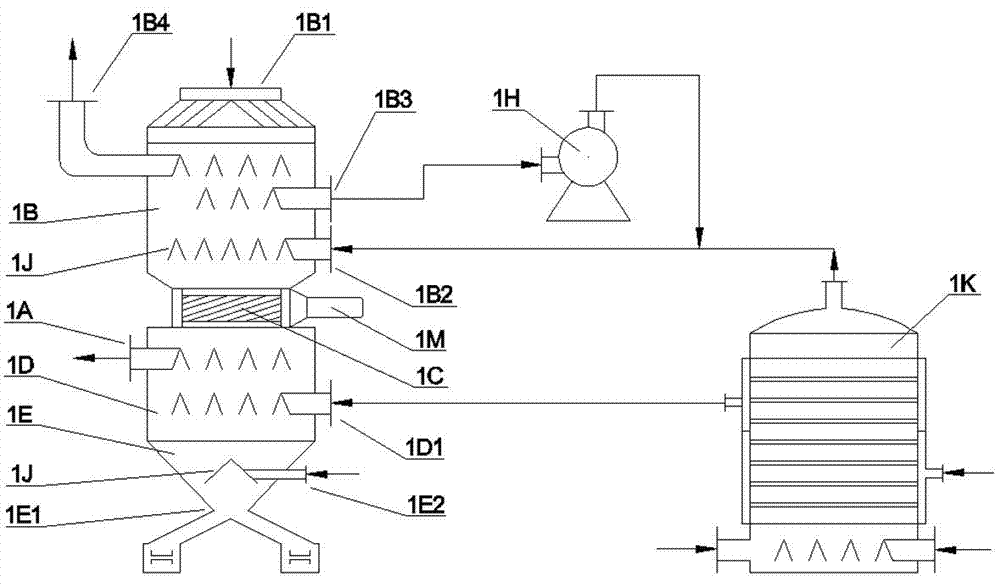

[0064] Such as figure 1 As shown, the specific steps are as follows:

[0065]1. Put the lignite lumps with a particle size of 15-18mm accounting for 83%, and the lignite lumps not greater than 25mm and greater than 18mm accounting for 17% into the drying and preheating section of the retort furnace. While moving at a slow speed, hot flue gas at 350-400°C is introduced from the lower part of the drying preheating section to directly heat the lignite block until the moisture content is less than 1% and the temperature is greater than 150°C, and 700°C is introduced from the middle or lower part of the dry distillation section. The high-temperature gas at ~750°C and the heating gas rising from the self-cooling section jointly heat and pyrolyze the lignite block step by step, and the volatile matter obtained from carbonization is collected by multiple rows of large-cavity angular boxes in the carbonization section of the carbonization furnace. Then enter the settling chamber with ...

Embodiment 2

[0071] 1. Put the oil shale blocks whose particle size is less than 80mm and not more than 75mm, accounting for 77%, and not more than 75mm and more than 70mm, accounting for 23% into the drying and preheating section of the retort furnace. The oil shale blocks are dried and preheated in the retort furnace, sealed The drying section and the retort section move slowly from top to bottom, and the hot flue gas of 300-350°C is introduced from the lower part of the drying preheating section to directly heat the oil shale block until the moisture content is less than 1% and the temperature is >110°C. The high-temperature gas of 650-700°C is fed into the middle or lower part of the retort section together with the heating gas rising from the self-cooling section to heat and pyrolyze the oil shale blocks step by step. Multiple rows of large-cavity angular boxes collect gas, and then enter the settling chamber with partitions through the oil-gas outlet through the oil-gas channel, s...

Embodiment 3

[0077] 1. Put lignite lumps with a particle size of 35-40mm accounting for 88%, and lignite lumps with a particle size of 35-40mm or less, and 12% of those larger than 35mm into the drying and preheating section of the retort furnace. Move slowly at a lower speed, introduce hot flue gas at 330-370°C from the lower part of the drying preheating section, directly heat the lignite block until the moisture content is less than 1% and the temperature is greater than 130°C, and pass in 680-370°C from the middle or lower part of the dry distillation section. The 720°C high-temperature gas and the heating gas rising from the cooling section jointly heat and pyrolyze the lignite block step by step, and the volatile matter obtained from carbonization is collected by multiple rows of large-cavity angular boxes in the carbonization section of the carbonization furnace, and then Enter the settling chamber with partitions through the oil and gas outlet through the oil and gas channel, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com