Releasing device for underwater robot and water surface high-speed unmanned boat

A technology of underwater robots and delivery devices, which is applied in transportation and packaging, ships, cargo handling equipment, etc., can solve the problems of large resource consumption and low fault tolerance rate, and achieve the effects of shortening delivery time, reducing accidents and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

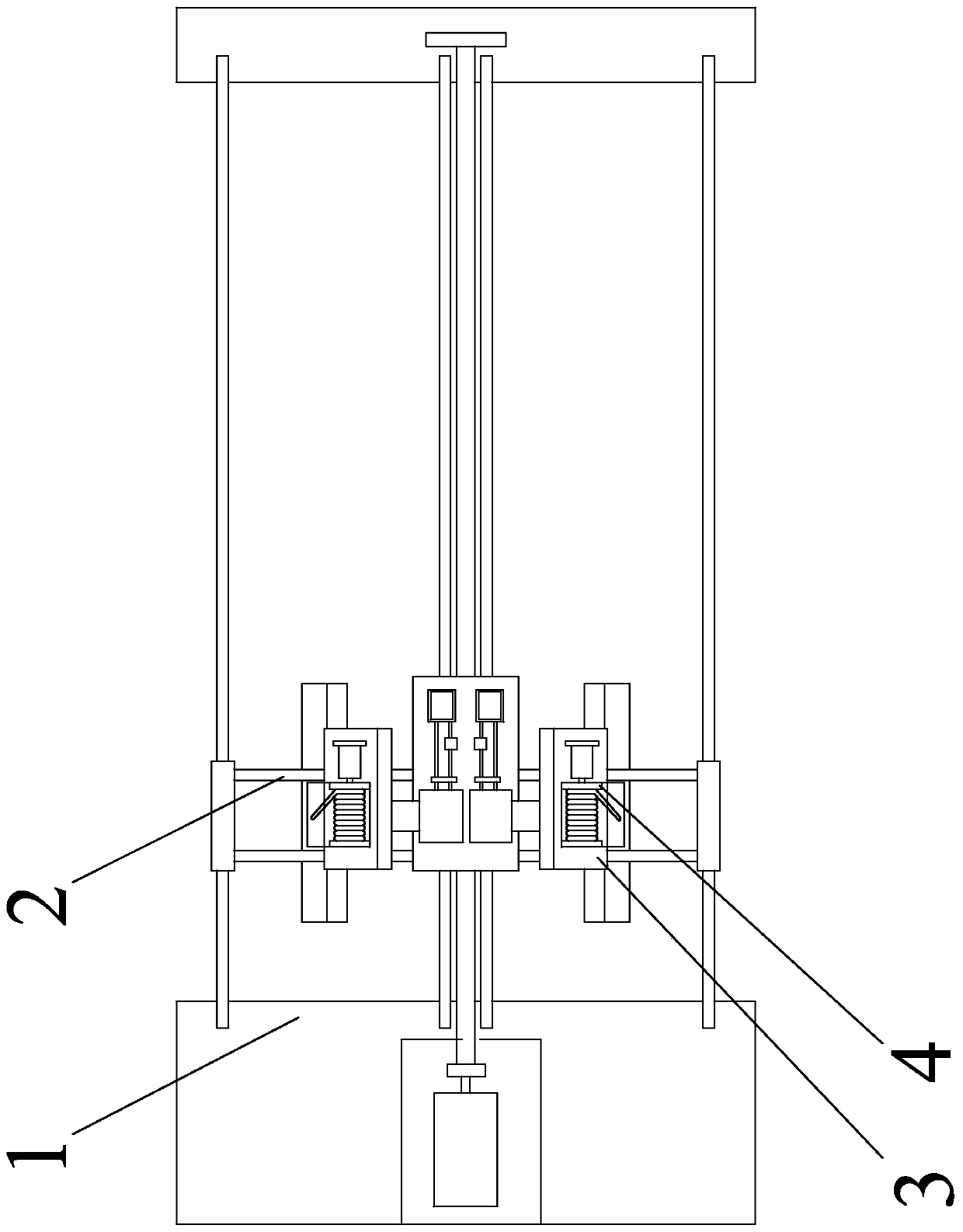

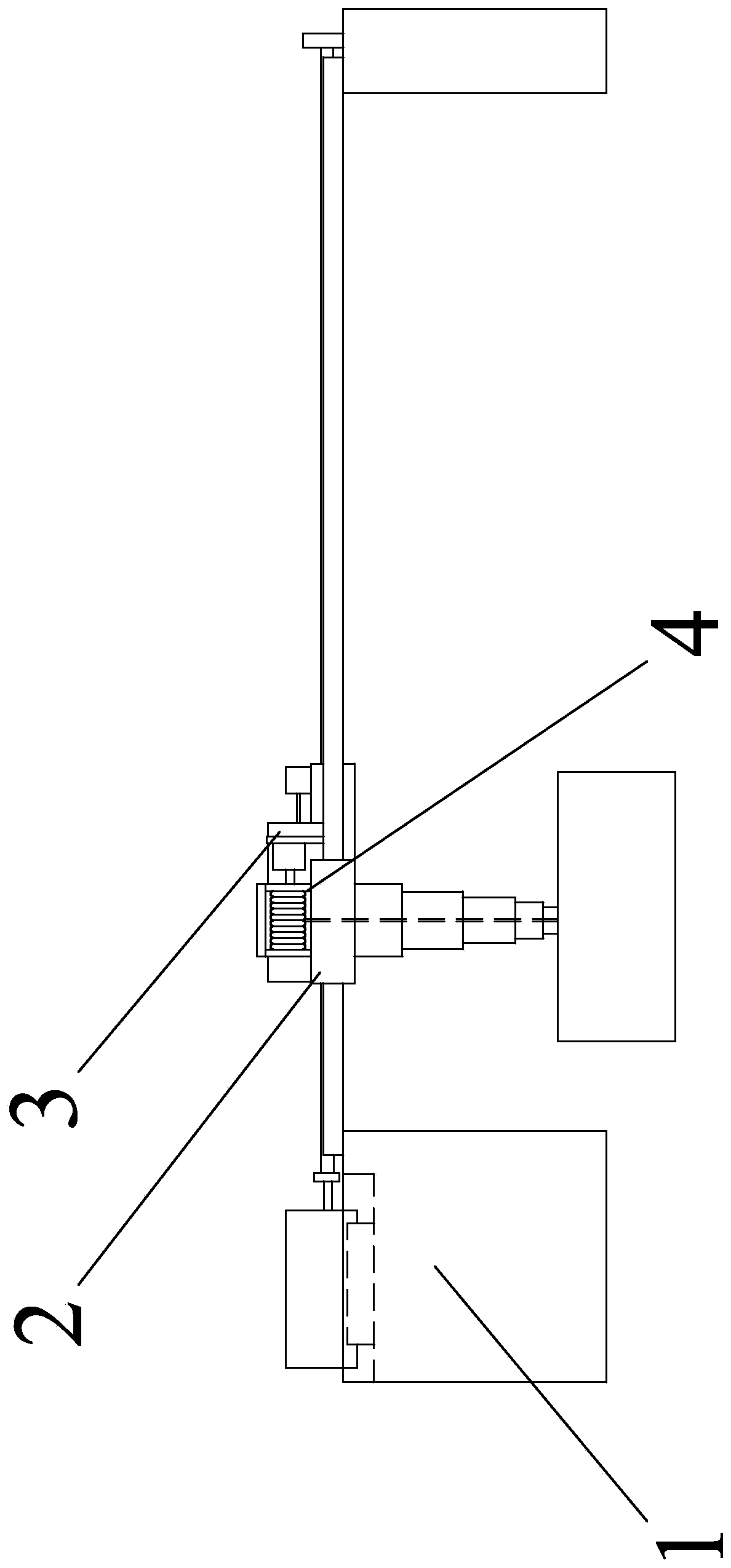

[0031] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, in this embodiment, a delivery device for underwater robots and surface high-speed unmanned boats, it includes a support mechanism 1, a workbench 2, two pushing mechanisms 3 and two lowering mechanisms 4;

[0032] The workbench 2 is slidably connected to the support mechanism 1, and two push mechanisms 3 are installed on the workbench 2, and the two push mechanisms 3 are arranged facing away from each other, and each lowering mechanism 4 is fixedly connected to one push mechanism 3.

specific Embodiment approach 2

[0033] Specific implementation mode two: combination Figure 8 Describe this embodiment, the support mechanism 1 in this embodiment includes a main support 1-1, a screw 1-3, an auxiliary support 1-4, a No. 1 motor 1-5, a shaft coupling 1-6, a bearing Bearing seat 1-7 and four slideways 1-2;

[0034] The main support 1-1 and the auxiliary support 1-4 are arranged oppositely, the No. 1 motor 1-5 is fixedly connected on the upper surface of the main support 1-1, and the output end of the No. 1 motor 1-5 faces the auxiliary support 1-4, Bearing seat 1-7 with bearing is fixedly connected on the upper surface of auxiliary support 1-4, and four slideways 1-2 are mutually arranged in parallel on the upper surface of main support 1-1 and auxiliary support 1-4, and each One end of the root slideway 1-2 is fixedly connected with the upper surface of the main support 1-1, and the other end of each slideway 1-2 is fixedly connected with the upper surface of the auxiliary support 1-4, and ...

specific Embodiment approach 3

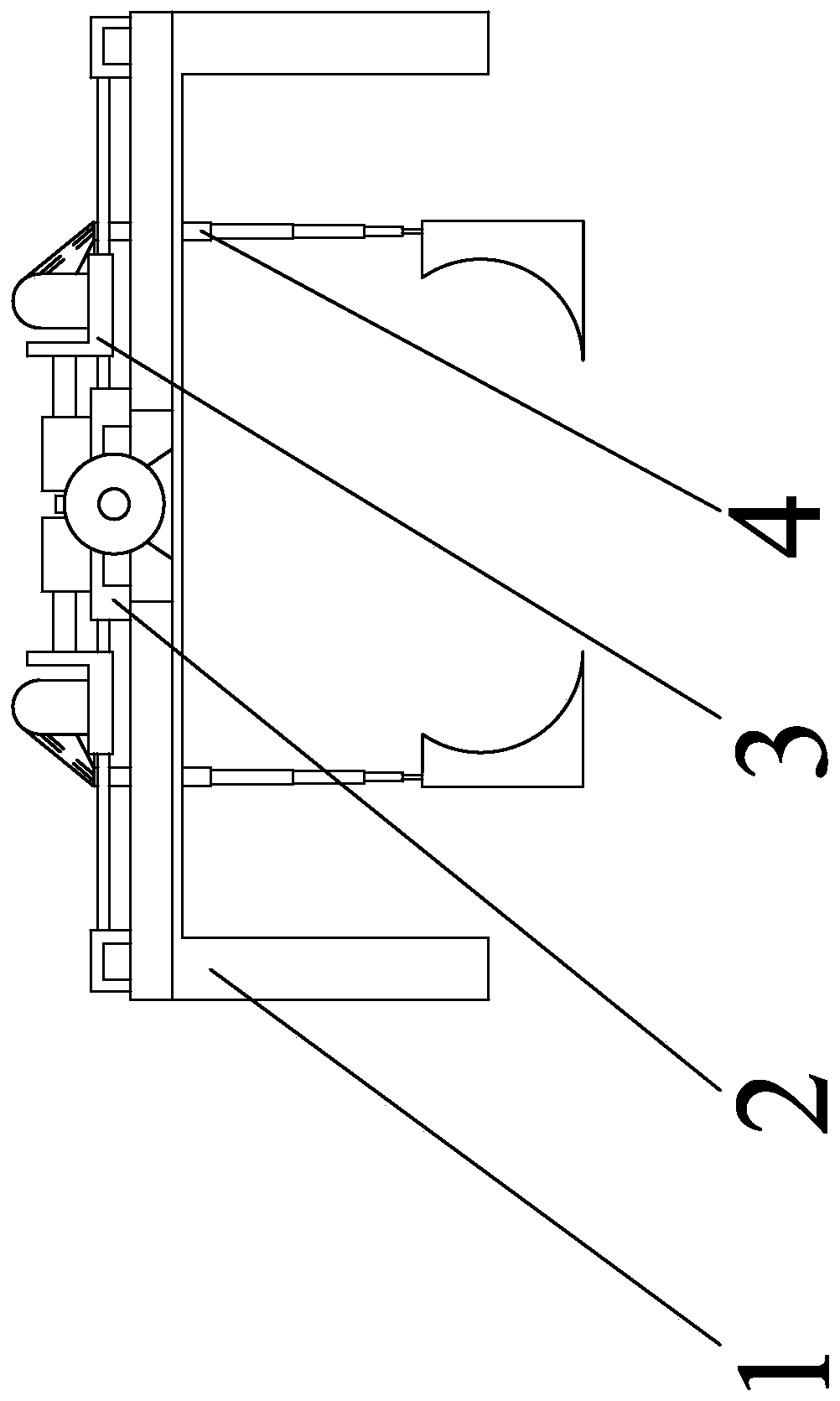

[0036] Specific implementation mode three: combination Figure 4 Describe this embodiment, the workbench 2 in this embodiment includes a work plate 2-1, two auxiliary slideway groups 2-2 and two auxiliary sliders 2-3;

[0037]Two auxiliary slideway groups 2-2 are respectively arranged on a side wall of the working plate 2-1, and one end of each auxiliary slideway group 2-2 is fixedly connected with a side wall of the working plate 2-1, each The other end of the auxiliary slideway group 2-2 is fixedly connected with the side wall of an auxiliary slide block 2-3, and the lower surface of the working plate 2-1 is provided with two parallel No. 1 slides along the length direction of the working plate 2-1. Slot 2-1-1, the middle part of the end wall of the working plate 2-1 is provided with a threaded through hole 2-1-2, and the lower surface of each auxiliary slider 2-3 is provided with a parallel to the No. 1 chute. No. 2 chute 2-3-1, lead screw 1-3 is set in threaded through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com