Process for preparing cement active mixed material and concrete admixture by using tungsten tailings

A technology of active mixed material and tungsten tailings, applied in the field of material science and engineering, can solve problems such as increasing production cost, water pollution, damage, etc., and achieve the effect of avoiding extraction and reducing expenses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

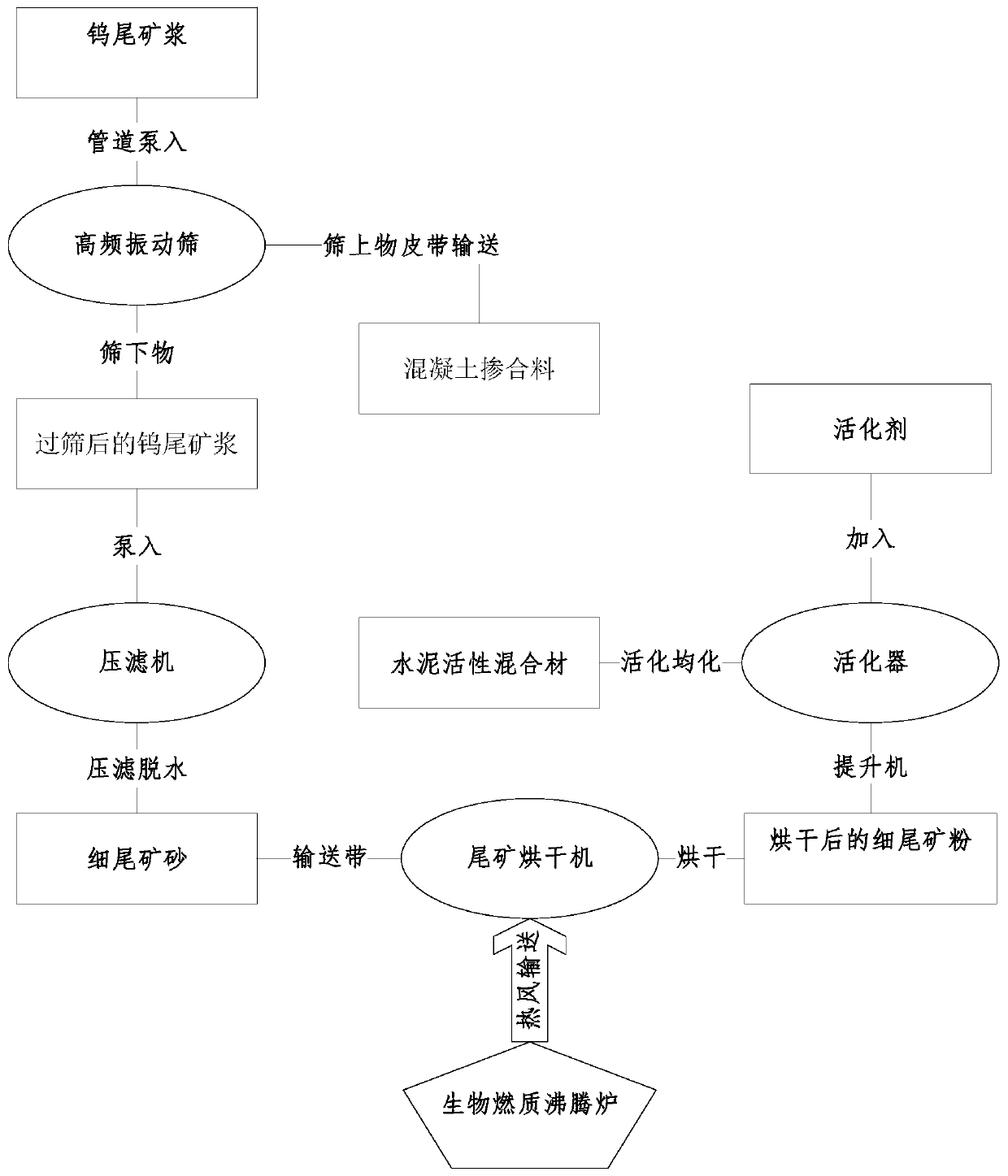

[0038] A process for preparing cement active admixture and concrete admixture with tungsten tailings, comprising the following steps:

[0039] Step (1): Screening of tungsten tailings

[0040] The tungsten tailings slurry to be treated is directly pumped to the tailings screening room through the pipeline, and the particle size is classified through the high-frequency vibrating screen. The material on the screen is coarse tailings sand, which is used as a concrete admixture for construction, and is transported by a belt To the tailings sand yard for storage; the screened tungsten tailings slurry is concentrated so that its moisture content is 62wt%;

[0041] Step (2): Press filter dehydration

[0042] Send the tungsten tailings slurry concentrated in step (1) into a plate-and-frame filter press with a thick slurry pump for pressure filtration and dehydration to become fine tailings, wherein:

[0043] The moisture content of fine tailings sand is 14.5wt%;

[0044] Step (3): ...

specific Embodiment 2

[0061] A process for preparing cement active admixture and concrete admixture with tungsten tailings, comprising the following steps:

[0062] Step (1): Screening of tungsten tailings

[0063] The tungsten tailings slurry to be treated is directly pumped to the tailings screening room through the pipeline, and the particle size is classified through the high-frequency vibrating screen. The material on the screen is coarse tailings sand, which is used as a concrete admixture for construction, and is transported by a belt To the tailings sand yard for stockpiling; concentrating the sieved tungsten tailings slurry so that its moisture content is 60wt%;

[0064] Step (2): Press filter dehydration

[0065] Send the tungsten tailings slurry concentrated in step (1) into a plate-and-frame filter press with a thick slurry pump for pressure filtration and dehydration to become fine tailings, wherein:

[0066] The moisture content of fine tailings sand is 14wt%;

[0067] Step (3): Dr...

specific Embodiment 3

[0080] A process for preparing cement active admixture and concrete admixture with tungsten tailings, comprising the following steps:

[0081] Step (1): Screening of tungsten tailings

[0082] The tungsten tailings slurry to be treated is directly pumped to the tailings screening room through the pipeline, and the particle size is classified through the high-frequency vibrating screen. The material on the screen is coarse tailings sand, which is used as a concrete admixture for construction, and is transported by a belt To the tailings sand yard for stockpiling; concentrating the sieved tungsten tailings slurry so that its moisture content is 65wt%;

[0083] Step (2): Press filter dehydration

[0084] Send the tungsten tailings slurry concentrated in step (1) into a plate-and-frame filter press with a thick slurry pump for pressure filtration and dehydration to become fine tailings, wherein:

[0085] The moisture content of fine tailings sand is 15wt%;

[0086] Step (3): Dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com