Polyurethane rework adhesive and preparation method thereof

A heavy-duty adhesive and polyurethane technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problem of removing LOCA residual adhesive, etc., and achieve improved rework yield, excellent elasticity, and good bonding sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

[0026] The components of the polyurethane heavy industry adhesives of Examples 1-7 and Comparative Examples 1-2 are shown in Table 1. The preparation method of embodiment 1~7 polyurethane heavy industry glue is:

[0027] (1) After mixing the silanized polyurethane prepolymer, pigments and fillers, and water-removing agent uniformly through a kneader, the excess water in the system is removed through high-temperature vacuum dehydration treatment;

[0028] (2) Move it into a planetary reactor and add a crosslinking agent under a vacuum of -0.085 to -0.095mpa and stir for 15 to 40 minutes; add a catalyst and continue to stir for 15 to 40 minutes; vacuumize to remove air bubbles and then pack to obtain polyurethane heavy industrial glue.

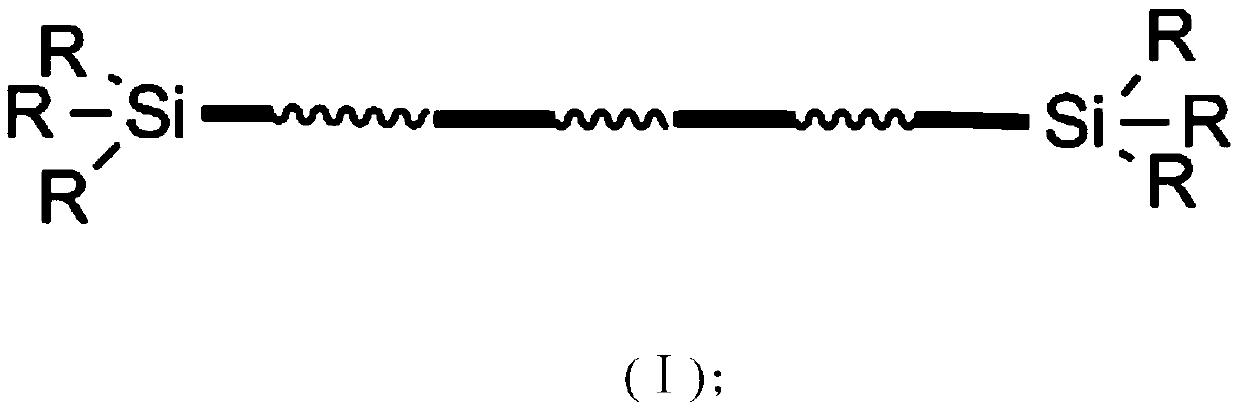

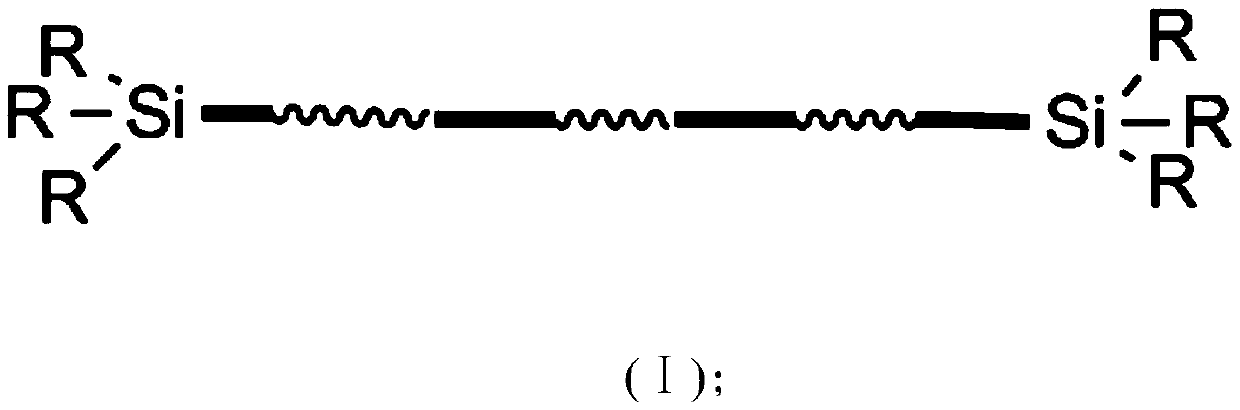

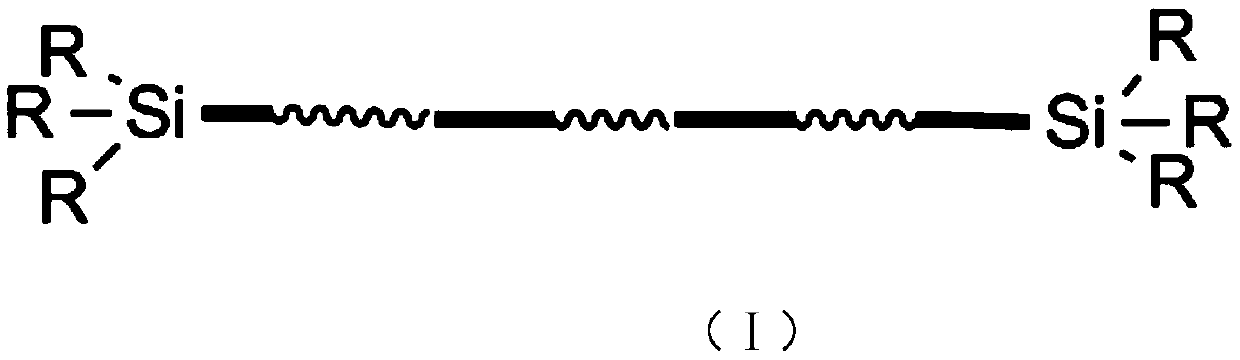

[0029] The structural formula of the silylated polyurethane prepolymer of the present invention is shown in (I) below:

[0030]

[0031] R in the formula can be one of methyl-terminated dialkoxy, methyl-terminated trialkoxy, phenyl-terminate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com