Greenhouse vibration snow plowing device and greenhouse with vibration snow plowing device

A greenhouse and vibrating machine technology, which is applied in the field of greenhouses with vibrating snow removal devices, can solve the problems of cleaning up the snow on the difficult roof, the inability of snow removal machines to remove snow, and the large area of the greenhouse roof, so as to achieve low energy consumption in operation , snow removal effect is good, the effect of prolonging the lighting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following examples describe the present invention in more detail.

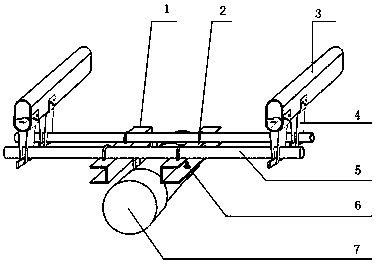

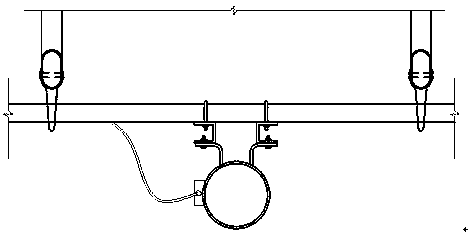

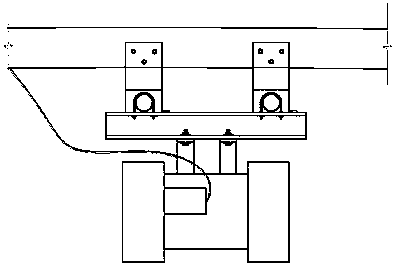

[0022] The first embodiment of the greenhouse vibratory snow removal device of the present invention is: two rows of symmetrical installation holes are opened on the mounting seat of the vibrator 7, U-shaped bolts are arranged on the steel arch frame 3 of the greenhouse, and the two ends of the U-shaped bolts Extend into two rows of symmetrical installation holes, and hang the vibrator on the arch of the greenhouse through nuts. This embodiment is characterized by simple structure, low cost and easy implementation.

[0023] The second embodiment of the vibrating snow removal device for the greenhouse of the present invention is: the installation frame is composed of two channel steels 1, two pull rod steel pipes 3 and U-shaped bolts 2, and two rows of symmetrical In the installation holes, two channel steels 1 are respectively fixed at two rows of symmetrical installation holes by bolts 6, and two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com