Electro-hydraulic compound servo loading method and device

An electro-hydraulic composite, servo motor technology, applied in the direction of fuel supply tank device, servo motor assembly, fluid pressure actuating device, etc., can solve the problems of low loading capacity, high cost, complex hydraulic equipment and pipelines, etc., to prevent control Dead zone, realizing the effect of load application, high precision and fast response load application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

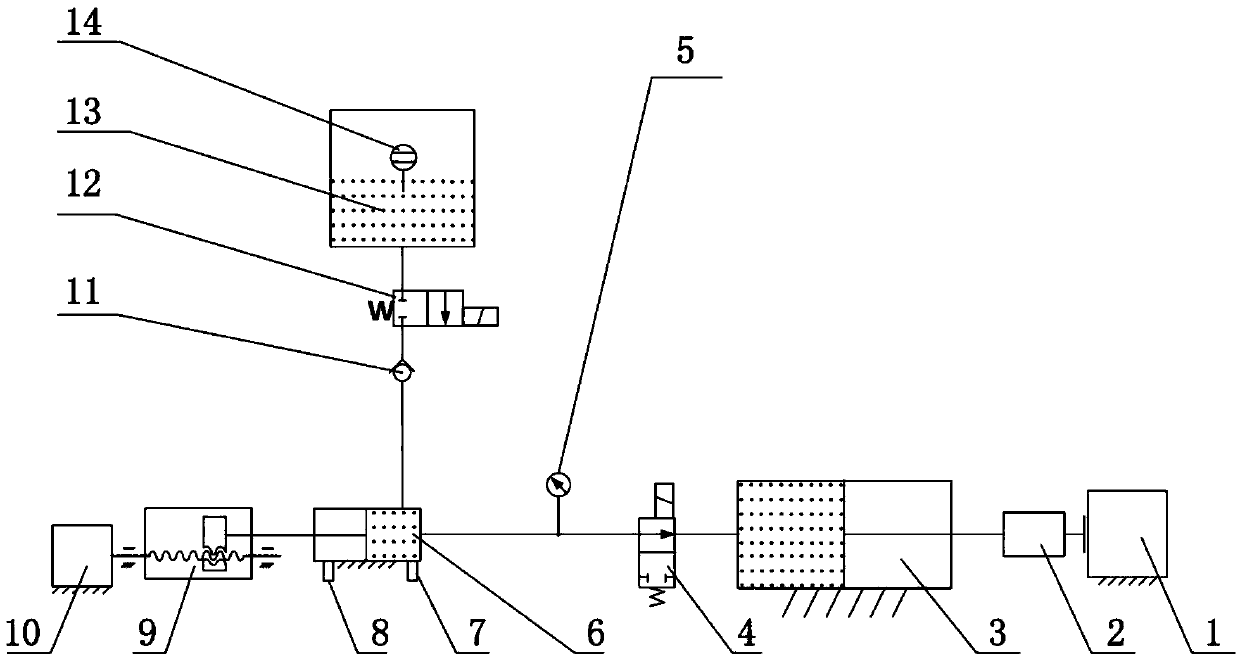

[0037] When loading, the servo motor 10 drives and controls the hydraulic cylinder 6 through the screw transmission, and the control hydraulic cylinder 6 drives the loading hydraulic cylinder 3 through the hydraulic transmission, and loads the loading object 1 after the loading of the hydraulic cylinder 3 is amplified, and the applied load is determined by the pressure gauge 5 or pressure sensor 2 to measure and read.

[0038] When the loading time reaches the set value, the system unloads. During unloading, the servo motor 10 reverses, and the piston rod of the hydraulic cylinder 6 is pulled and controlled by the screw transmission system to retreat to realize unloading.

[0039] If there is insufficient oil due to leakage during the loading process, the control hydraulic cylinder 6 will keep moving forward, triggering the travel switch set at the limit operating position at the front end of the cylinder body, that is, the oil shortage limit switch 7 to send out an oil shortag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com