Three-way control valve structure

A three-way control valve and valve body technology, applied in multi-way valves, valve details, valve devices, etc., can solve the problems of single structure, unsatisfactory use effect and service life, damaged valve body, etc., and achieve good sealing effect. , good economic use value, prolong the service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

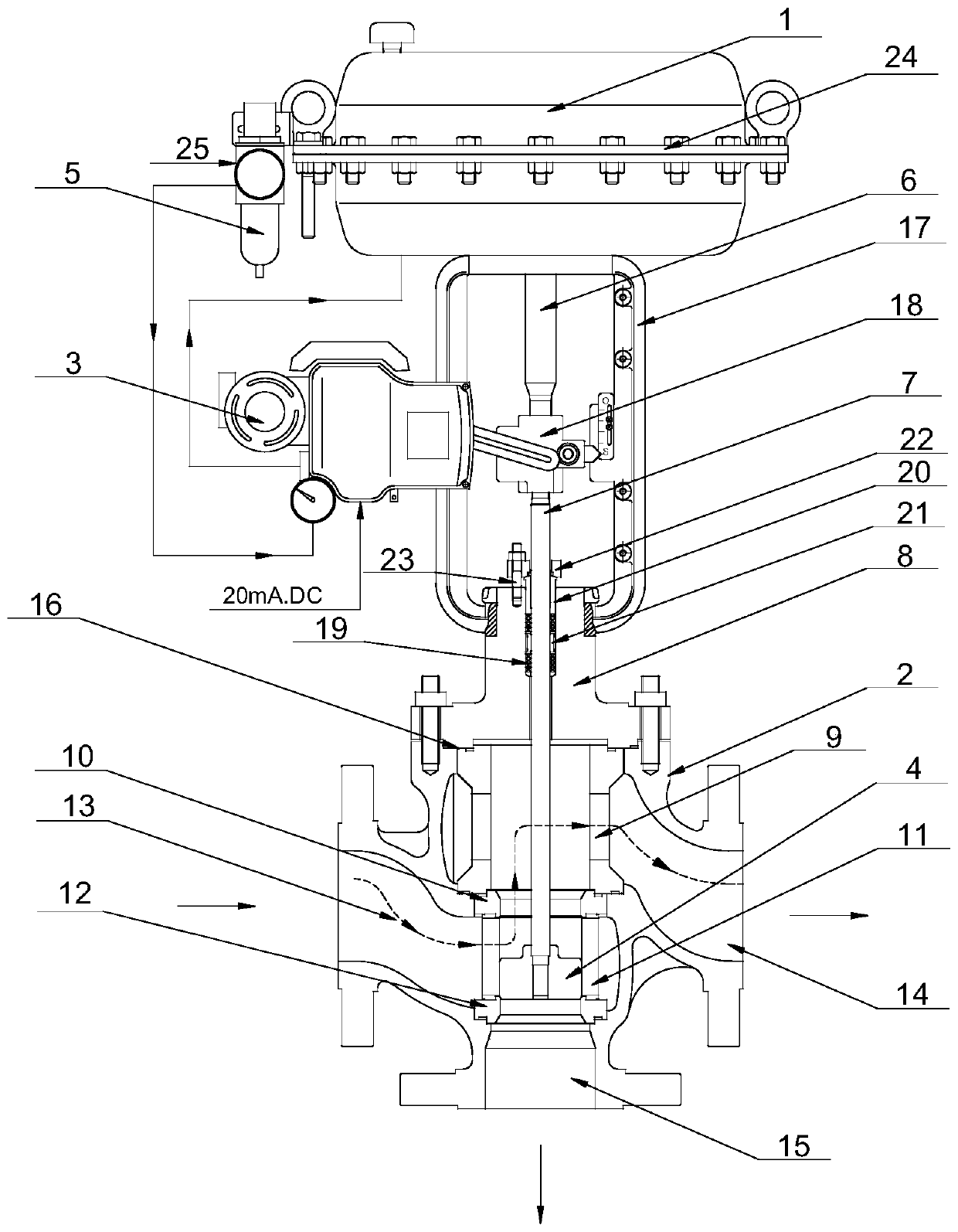

[0019] Such as Figure 1 ~ Figure 3 As shown, the present invention includes a valve body 1, an actuator 2 and a locator 3 connected to the actuator 2. The valve body 1 is a four-way structure, the valve body 1 is provided with a valve core 4, and the input end of the actuator 2 is provided There is a pressure reducing valve 5, the output end is connected with a push rod 6, the push rod 6 is connected with the valve stem 7, the lower end of the valve stem 7 passes through the valve cover 8 and then extends into the valve body 1 to connect with the valve core 4, the valve cover 8 is fixedly connected with the valve body 1, and the valve body 1 is provided with a balance cylinder 9 and an upper valve seat 10, a sleeve 11, and a lower valve seat 12 with the same inner diameter in sequence from top to bottom, and an upper valve seat 10, a sleeve 11, and a lower valve seat 12. The valve seat 12 is set at the flow port of the valve body 1, the sleeve 11 is sleeved on the outer wall ...

Embodiment 2

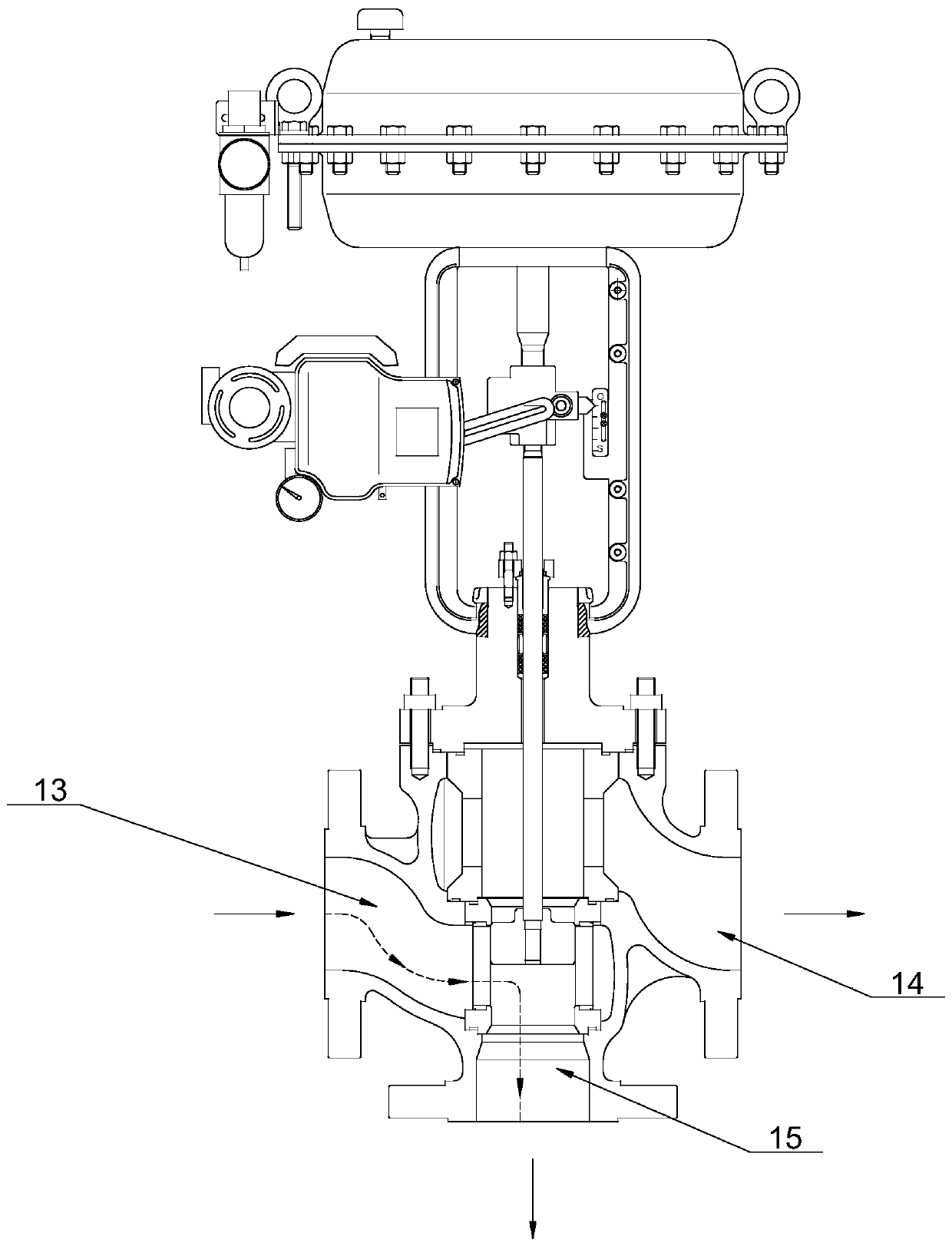

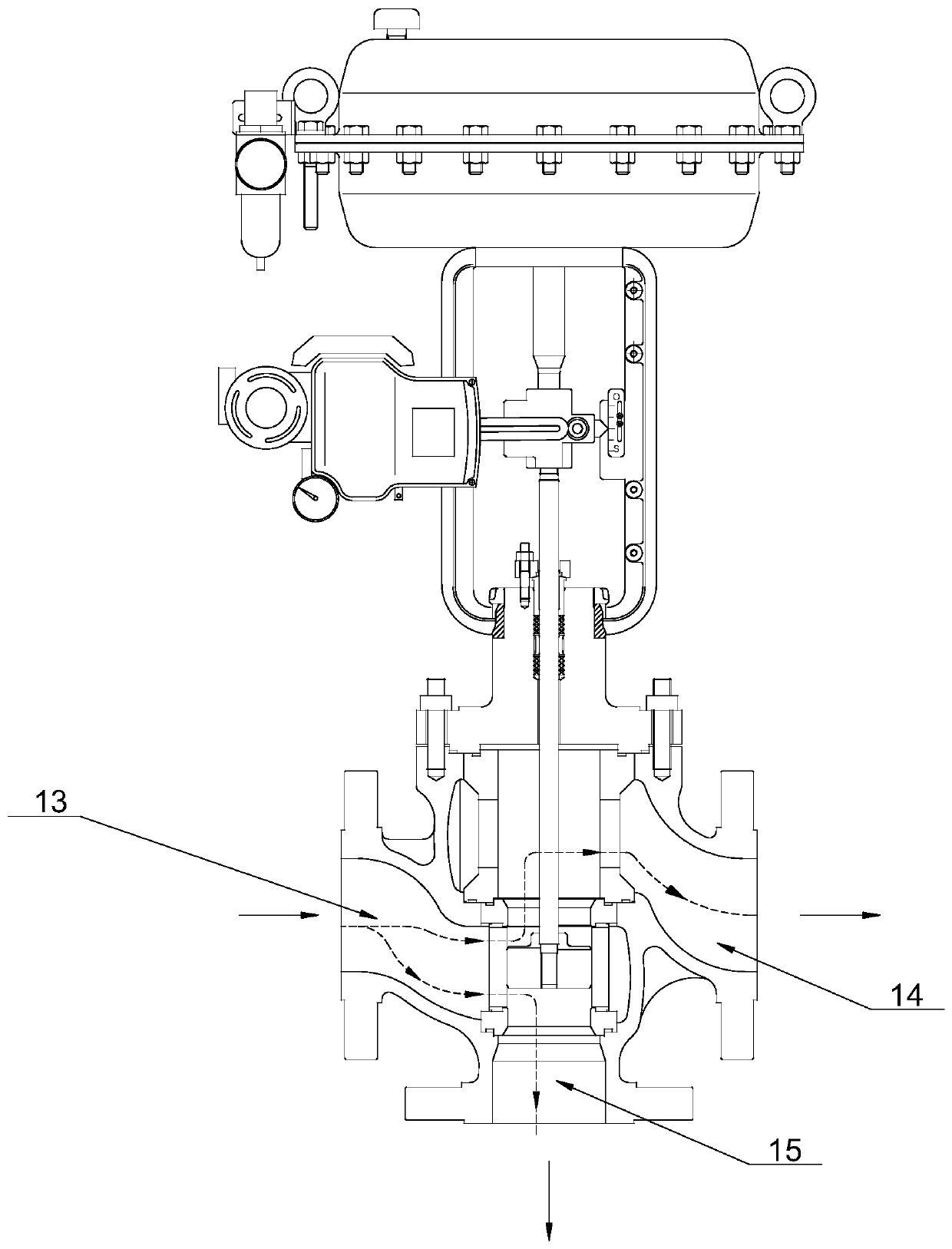

[0030] When there is a signal, the actuator 2 raises the valve core 4 under the action of compressed air, and the valve core 4 is in close contact with the sealing surface of the upper valve seat 10, thus closing the flow port II14 and opening the flow port I13, flow port Ⅲ15, such as Figure 5 As shown; when there is no signal, the actuator 2 pushes the spool 4 downward by the elastic force of its own spring return, so that the spool 4 descends, and the spool 4 is in close contact with the sealing surface of the lower valve seat 12, thereby closing the flow port III15, The circulation port Ⅰ13 and the circulation port Ⅱ14 are opened, such as Figure 4 As shown; where the spool 4 is under the action of the positioner 3, the spool 4 can be placed at different heights of the window of the sleeve 11, and the purpose of adjusting the fluid flow can be played. At half the height of the window, the fluid medium is in a confluent state, such as Image 6 shown.

[0031] Figure 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com