Combined integrated steam evaporator

An evaporator and steam technology, which is used in steam generation, steam boilers, steam generation methods using pressure combustion, etc., can solve the problems of less flue gas return, slow steam output time, low utilization rate, etc. The effect of raising temperature and saving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

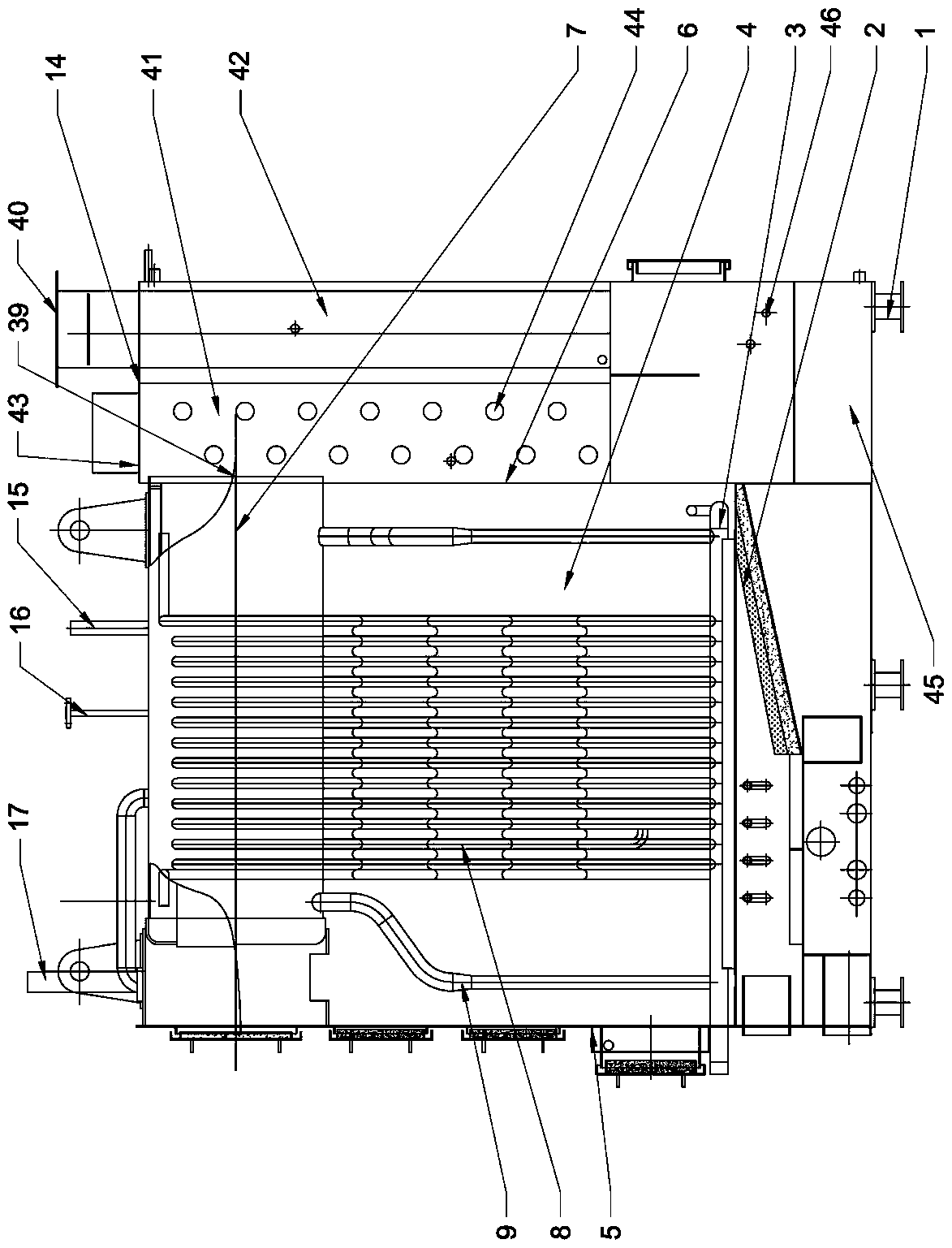

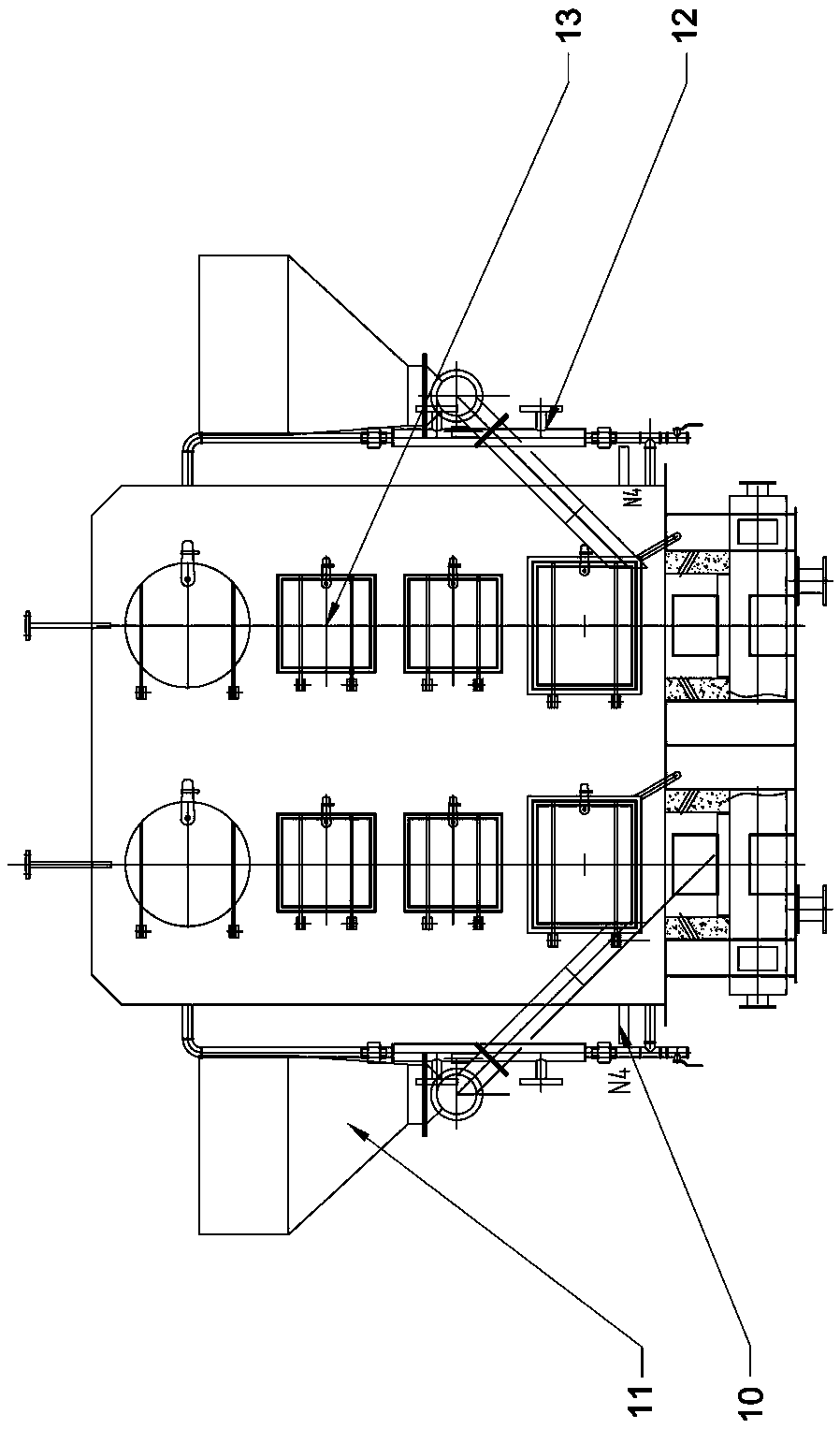

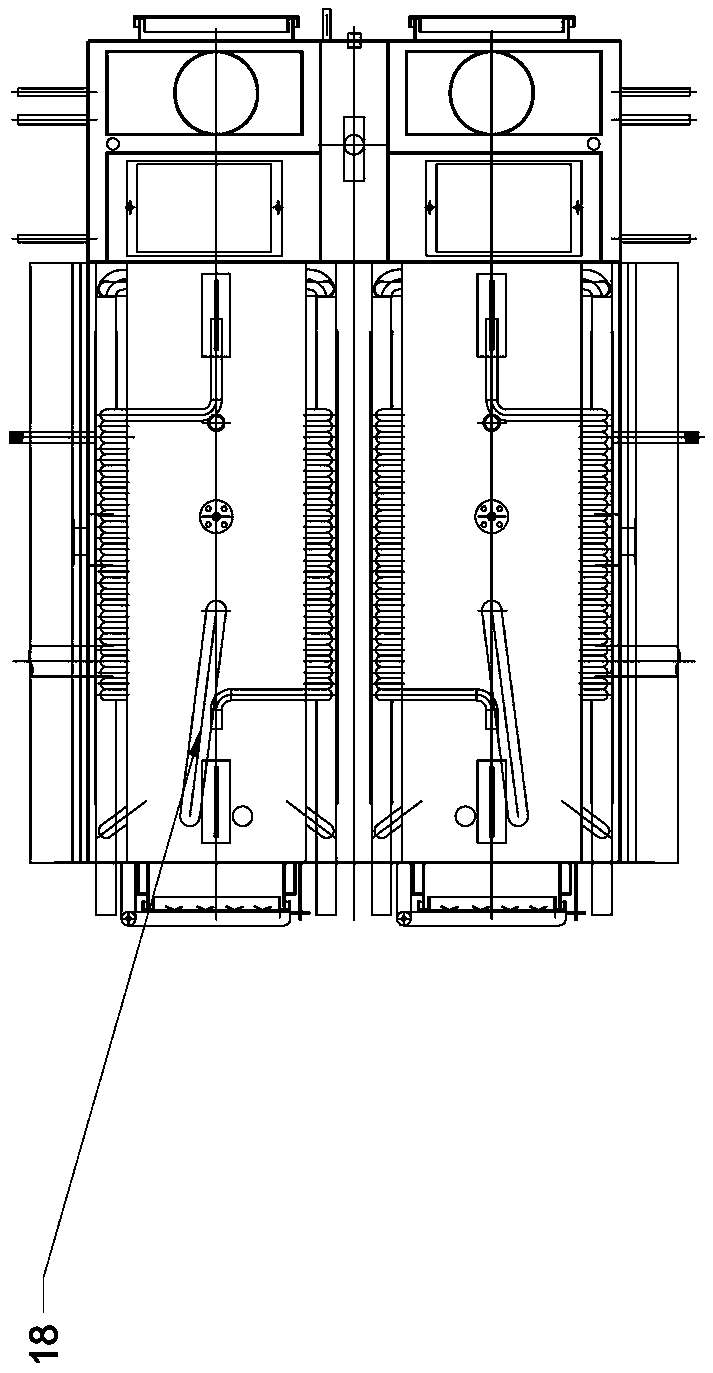

[0029] Such as Figure 1-12 As shown, the object of the present invention is achieved in the following way: A combined integrated steam evaporator includes an evaporator body, the evaporator body includes a base support 1, a grate assembly 2 arranged on the base support 1, and arranged on the furnace The lower header 3 on the row assembly 2, the intermediate furnace 4 arranged on the lower header 3, the front panel 5 arranged in front of the intermediate furnace 4 and the rear panel 6 arranged behind the intermediate furnace 4 respectively; the intermediate furnace 4 Correspondingly, there is a cylinder assembly 7 on the top, and several groups of serpentine heating surface tube assemblies 8 are arranged between the cylinder assembly 7 and the lower header 3. 6 are arranged in sequence; between the cylinder assembly 7 and the lower header 3, several groups of downcomers 9 are arranged in cooperation, and several groups of the evaporator body are arranged side by side, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com