Microwave sensor for measuring dielectric constant and magnetic conductivity of magnetic medium material

A technology of microwave sensor and dielectric constant, applied in the field of microwave, can solve the problems that it is difficult to measure the dielectric constant and magnetic permeability of magnetic medium materials, it cannot measure the dielectric constant and magnetic permeability at the same time, and the sensor has a single function. Achieve the effects of high sensitivity, high sensitivity and Q value, and ensure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below with specific embodiments in conjunction with the accompanying drawings.

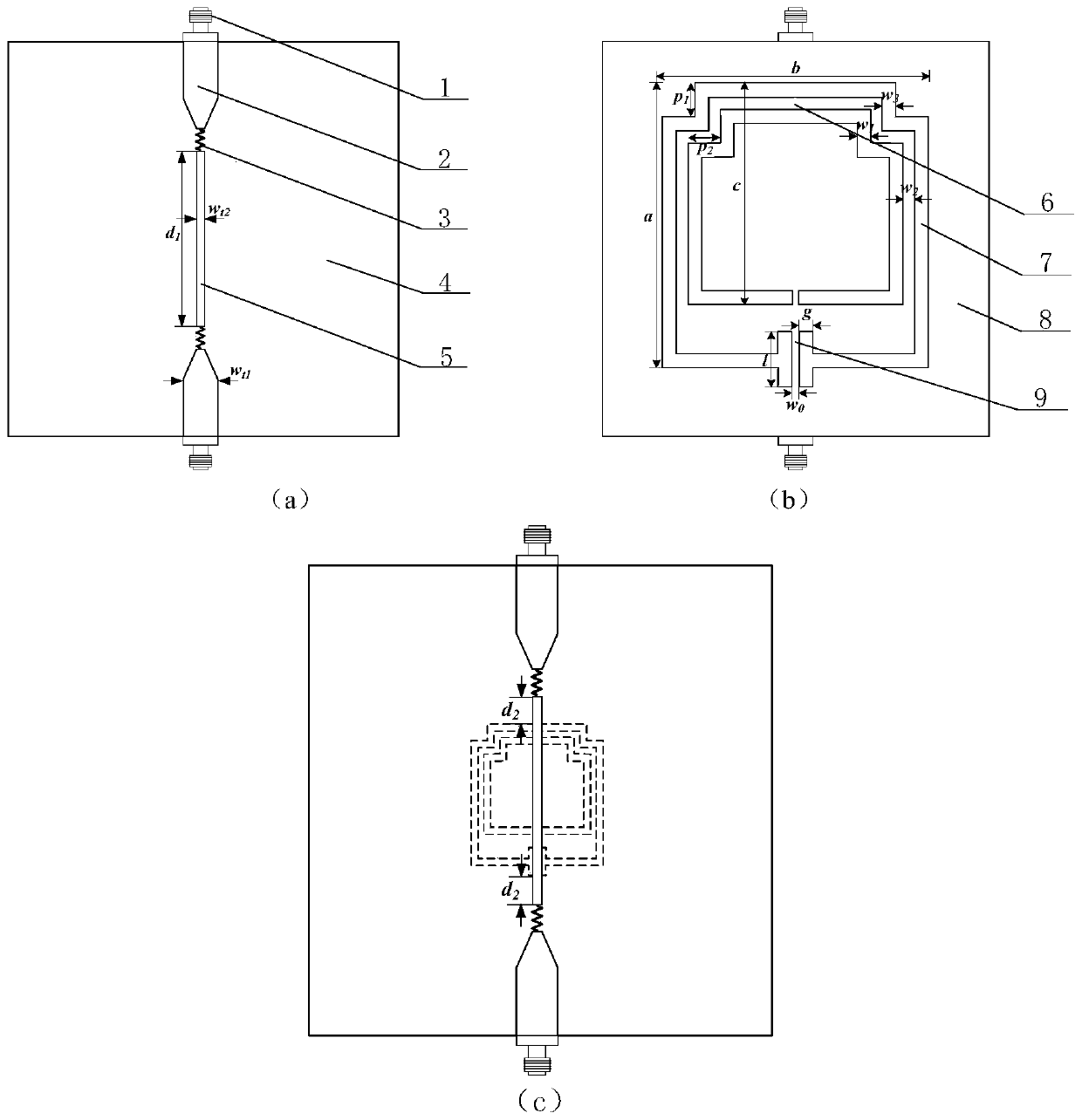

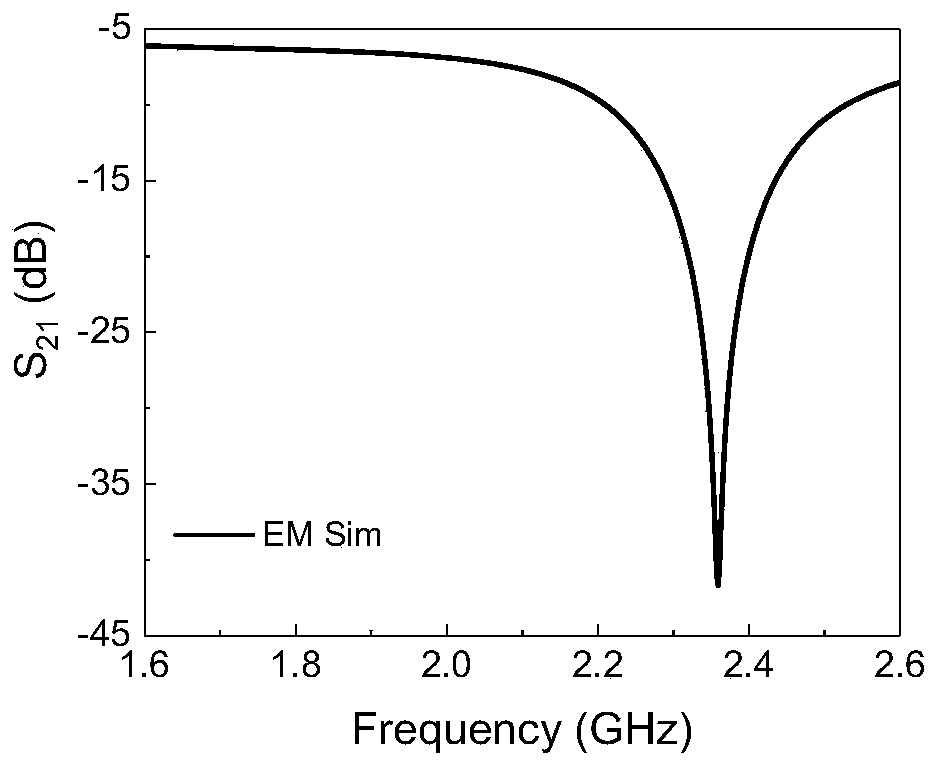

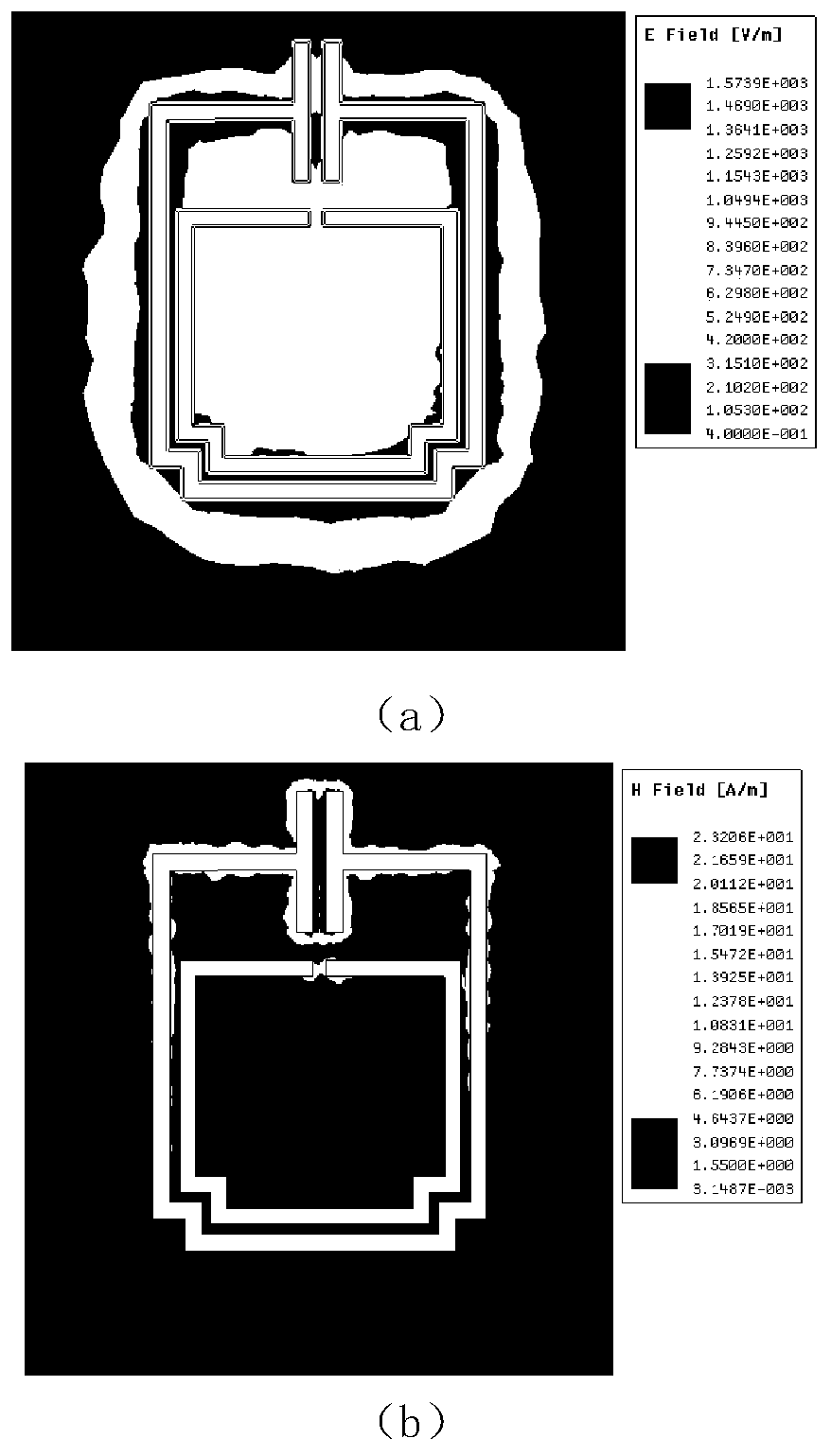

[0027] Such as figure 1 Shown is the structure schematic diagram of the present invention, and the sensor of the present invention comprises the CSRR slot ring 7 that top layer microstrip line, middle layer PCB board 4, bottom metal sheet 8 are etched; Top layer microstrip line includes two sections of microstrip line I2 and A section of microstrip line Ⅱ5, a section of the first microstrip line Ⅰ and microstrip line Ⅱ5, and the other section of the first microstrip line Ⅰ and microstrip line Ⅱ5 are respectively welded through two 50Ω resistors 3, and the microstrip line Ⅰ2 is extended to feed The long pin is used to connect the SMA connector 1; the microstrip line II 5 is coupled to the underlying CSRR slot ring 7;

[0028] The grooved metal CSRR structure is composed of inner and outer groove rings; the inner and outer groove ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com